The process of smoking products is applied by people for a long time. Fish, meat and even cheeses, after processing smoke, not only amazing flavor and attractive appearance, but also stored much longer. Currently, products are sold in grocery supermarkets, smoked with the help of the so-called "liquid smoke" - chemical composition, after processing which they become similar to products with real smoke smoke, but only externally. Naturally, nothing can replace natural smoke branches of oak or cherry with the addition of twigs of juniper, which give smoked splashes and fragrance.

Content

To cook smoked product, you need to have a special device - smoking. Cottlen designs are quite a lot, ranging from compact portable devices to large semi-dimensional chambers. However, the principle of their work is the same. Make a smokehouse is not too difficult for yourself, since its work does not provide for complex processes. At the same time, it is possible to use for this process, everything that is at hand, ranging from the old bucket, and ending with the housing of the refrigerator, failed. About how to make a smokehouse for giving with your own hands, let's tell further.

Smoking processes of food and varieties of smokehouse

In order to make the smokehouse with their own hands, it is necessary to understand what processes pass inside it and how to prepare smoked smoking.

There are two process of smoking products that differ in both their current and the quality of the outgoing dish. Constructions for these processes will have differences, so when choosing the most optimal product, it is worth thinking about which product is given as a result:

- Hot smoking. In this type of process, flue gases that are treated with meat or fish, have a high temperature. Due to the fact that the furnace is located at the bottom of the smoke mine, smoke does not have time to cool while it comes to the products located in the mine. As a rule, the process flows 2-3 hours until complete readiness depending on the number of products and sized pieces. Due to the high preparation temperature, the products do not have time to give all moisture, due to which they remain juicy and soft. The reverse side of the hot smoked is that the cooked products cannot be stored for a long time. Extend storage time you can only dry them. The advantage of hot smoked smoking is a simple design, thanks to which you can make a portable version of this product.

- Cold smoking. As you can already understand from the name, smoke, which are processed by delicacies, loses its temperature, on the way to them. Because of this, the cooking process slows down, and the products are losing almost all their moisture. Due to this, the storage time is significantly increasing. This was the reason that this smoked method became more popular.

The main principle of operating the smokehouse of any design is that the smoke is distinguished by non-burning firewood, but the smoldering chip, which heats up from firewood. As chips, finely chopped branches are usually used. In order for the smoke to be thick, it is possible to put a little fresh herb to chips.

Hot smoked smoking smoking technology

The manufacture of hot smoked smoking does not represent anything complicated. The difference from models intended for cold smoking is that the furnace for creating a high temperature for the production of smoke is directly under the smoke chamber.

For the manufacture of a simple smokehouse will need:

- Metal barrel volume of 200 liters.

- Bricks - 6 pcs.

- Metal rods (you can use a wire with a diameter of 4 mm).

- Cement, sand.

- From the tool you will need Bulgarian, electric drill.

Order order:

- First of all, it is necessary to clean the barrel from the remains of the substances that were stored in it. An ideal option will use a barrel from alcohol. It does not require special processing. If it used to stored butter or other petroleum products in it, then it must be carefully flushed and evaporated.

- After that, in the barrel, you must remove the lid. It is possible to do this with the help of an electric bike or a grinder. It is necessary to work very carefully, applying mittens and protective glasses. Cutting the cover, you need to handle the edge with a file, finally removing the residues of the metal.

- The housing of the smoke of the metal barrel is almost ready. In order to place in it a ride to hang out products, at a distance of 150 mm from the top edge you need to drill 6 holes in a circle. Their diameter should be 2-3 mm more than the diameter of the jerdoma. If the latter is used for the latter with a diameter of 4 mm, the holes must be at least 6 mm.

- A slightly above must be drilled by several holes to remove smoke from the smoke chamber. They should be at least 12.

- Now at the bottom of the barrel you need to cut a hole to load sawdust. It is cut with a grinder. Next to it welded the door on the hinges. If the loading hole is not closed, smoke will pass through it.

- As the top cover can use a wooden board, by which to enclose the seal segment burlap or other dense tissues.

- The next step must be built an improvised barrel furnace. To do this, you need to dig a small pit, fall asleep with gravel and pour concrete. After it dries, 6 bricks are placed on its surface: 2 rows of 3 bricks. It is necessary to do it so that the barrel on them stood smoothly and not swinging. Bricks are put on the usual cement-sandy solution.

The process of smoking in such ancitel is quite simple. Prepared products are suspended by the trap thread of large diameter and suspended on the rod. Through the loading hatch to the bottom of the smoke, the chips are stacked, purified from the crust. The top of the smoke is sealed and closed with a shield. The fire is divorced at the bottom, and the smoking process lasts 2-3 hours until the preparedness of the products.

Instructions for the manufacture of smoked smoking

It is somewhat different from the above that the flue gases approached to the smoke chamber have already managed to lose temperature. To do this, the location of the firewood is separated from the camera with a long branch.

For this work, you will need:

- Metal box or barrel. An excellent option can be the housing of the old refrigerator, which must be cleaned of plastic and rubber parts. Leave only metal. Since the door is made of fine iron, it is better to enhance it with a small steel corner. The bottom of the box can be completely cut.

- Metal or ceramic pipe 3 meters long.

- Brick.

- Solution.

Installation is performed in the following sequence:

- First you need to dig 2 pits. One of them will perform the role of firebox, the smoke chamber will be installed above the other. The size of the second pit must correspond to the size of the smoke cabinet. There is a trench between the chimney styling. Its depth must be at least 50 mm plus the diameter of the pipe itself.

- For chimney, it is better to use ceramic pipes. Such are often used to mount the chimney in the heating systems of residential buildings. The advantage of this material is not subject to corrosion.

- I dug the trench, it is necessary to lay a small layer of sand, which should then be mounted the pipe (it is released by sections). It is necessary to do this in such a way that its ends come out behind the walls of the same pits.

- On the bottom of the holes layer of gravel and sand. Then the wells are laid out of the brick. At the same time, the protruding tube is placed brick. The height of the fuel well should be 1 brick above the ground level, the height of the well on which the camera will stand - 3 bricks above.

- After the brick laying is over, the distance between it and the walls of the holes falls asleep with sand.

- Now on the surface of the well, where the smoking chamber will be installed, a grate grid is mounted. It is needed in order to put the pallet for fat. After that, a metal drawer is installed on the surface of the well. If the "raw" metal is used, it is better to operate it with several layers of heat-resistant paint. In the side parts of the box, holes should be made to exit part of smoke.

- It is also necessary to adjust the door so that it closes tightly.

- In the chamber are installed in the pendant of the products.

Making a hiking homemade smokehouse with their own hands

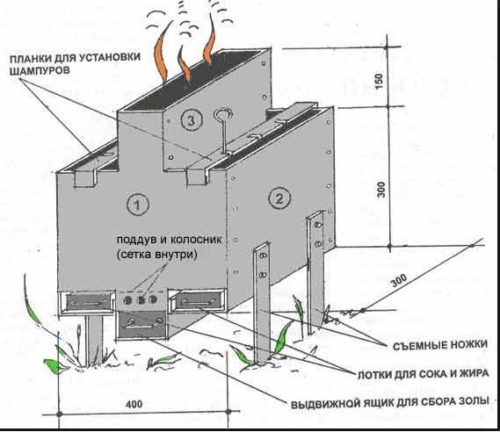

In order to make a hiking variant of smokehouse, which is useful during fishing or picnic, it is necessary to make a box with a tightly closing lid from a thin sheet metal. The sizes of the box are selected individually depending on the volume of products that are planned to smoke. Next, work is performed in the following order:

- In the middle of the drawer height, a removable grill is installed for booking. A hole for the exit of smoke is done in the lid, and the pens are attached on the sides.

- This portable smoke can easily fit in the car's trunk, and it is quite simple to use it.

- The bottom of the box is stacked small wooden lumps peeled from the crust. You can use wood chips. Then the lattice is installed on which prepared products are stacked. After that, the box is covered with a lid and is installed on the fire.