Even the most primitive work is difficult to fulfill without the use of the tool. And in order to deal with the metal, a special tool is needed - metal-cutting. About its appointment, species and production will be discussed in this article.

Content

Metal cutting tool. What is needed and requirements for it

The metal-cutting tool is necessary when processing metals by cutting. The layers of material in order are separated and go into waste - chips. Thus, at the end we will have a semi-finished product or product, which it was intended. The metal-cutting tool must meet the main requests:

- operated with proper return;

- perform work with a guarantee of given tolerances.

To all, he must:

- do not lose the working state after non-disposable effects. Time in minutes during which it will be operated from one bed to another, determines the tool resistance;

- securely secured in the shortest time.

Views

- The metal cutting tool, the types of it are conventionally rank to:

- manual;

- machine.

Manual metal processing tool

A group of metal-cutting tools that can be operated without attaching it to equipment is classified as manual. So use:

- chisel;

- manual hacksaw;

- shabra;

- files;

- nadfils;

- tags;

- dies (Lersky).

Many have acquired drills, perforators, corner-glazed machines that feed from electricity, working from hydro and pneumatic actuators, and their active part is the same tool that is called manual. There are sets of tools on sale, which is very convenient. Well, for example, take at least:

Bison 28119-H110

- The manufacturer is the Russian company "ZOMB". Having in the farm such a set will be possible:

- performing metric threads in holes, both with normal and small pitch;

- cutting the tubular thread, both in the holes of dead end and end-to-end;

- get the exterior thread, on steel products, and from metals belonging to color.

The composition and features of the Komson kit 28119-H110 of 110 items:

- dice (lark), taps. Material - Steel 9xc Alloy tool;

- a suitable drill is attached to each taker;

- for drills having an above-handed profile and a cross-shaped statement, the material is the high-speed steel; The kit is equipped with tester-holders having a screw mechanism that locks the shanks. Laid the opportunity to regulate it;

- you can easily approve the threads in places with limited access due to the presence of a skipper-holder with a special chain.

Metal cutting machines and tools

The definition of metal cutters, the following machines fall:

- drilling;

- turning;

- revolving;

- boring;

- coordinate boring;

- milling;

- planing.

The metal-cutting tool, which is used as machine, has such zones:

- Clamping. This is the part that is fixed in the cartridge of the machine in a strictly required position;

- Cutting or calibrating, having direct contact with the part. This includes the following elements:

- blades;

- grooves to exit chips;

- chipsautifiers;

- channels for which the lubricant or fluid is cooled;

- basic elements, etc.

The form of these parts is different, but still, for all products, the constructive design of the part of the cutting does not have many variations. All of them include:

- front surface;

- miscellaneous number of rear surfaces.

What kind of data is given to the cutting tool, is determined by the orientation of the working surfaces regarding the part when working with it. Looking at what task the machine tool is performing, it is referred to:

- coatless;

- making or processing holes, and such an operation also includes drilling, and zenching, and deployment;

- abrasive;

- diamond;

- thread-cutting.

Cutters

The cutters are an actuator for machines:

- turning;

- planing;

- fucking;

- boring;

- turning and revolving;

- carousel.

Operations performed using cutters

With the help of cutters:

- decorated and robing holes;

- processing surfaces complicated and absolutely smooth;

- sleep the grooves.

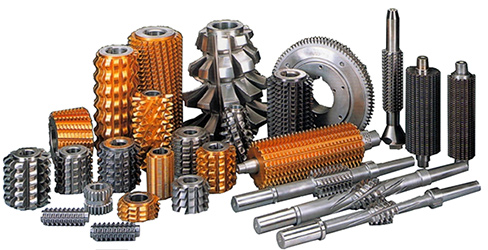

Cutters

Cutters are placed on milling machines. They have a lot of sharp sharpened blades and rotating, perform:

- operations with the most different planes;

- cutting blanks.

Stripping from the geometry and the position of the cutting blades in relation to the instrument, which makes the rotational movement, cutters are:

- cylindrical. They are an active working body for horizontal milling machines;

- forky. Equipped with vertically milling machines;

- end. They are treated with large depths;

- disk, without which milling grooves, grooves are not possible;

- corner. When they are assisted, there are grooves corner and plane inclined;

- shaped, which are treated with all sorts of shaped surfaces.

Broach

The tool has many cutting edges, adapted for operation on an outcrop. It is processed:

- holes passing through;

- exterior surfaces.

On the shaping form can be:

- cylindrical;

- married;

- keyword;

- slotted;

- shaped external;

- flat outdoor.

Tools intended for performing and processing holes

Tools forming and machining holes are presented:

- sweeps;

- drills;

- cekhovka;

- zenckers;

- boring plates;

- zenkovka;

- combined tool.

Tool tool tool

The brown tool is cut and processed:

- gear wheels;

- worms;

- toggle rails.

This group includes:

- lari (dice);

- taps;

- thread cutters;

- cutters.

Abrasive tool

Abrasive tool is performed:

- grinding;

- polishing;

- digging.

The list consists of:

- honing heads;

- circles for grinding;

- emery caved;

- bars.

Diamond tools

The cutting part is diamond. Diamond is not necessarily natural, sometimes synthetic. The species is presented:

- hona;

- bars;

- grinding circles;

- cutters;

- cutters having diamond plates;

- fILERS, etc.

What affects the quality of the metal cutting tool

The ability to fulfill the task is well due to many factors, namely:

- as executed sharpening cutting part, at what angle, what is her configuration;

- those properties are endowed with the material from which the working part is manufactured;

- depth, speed of cut, feed.

Material for the cutting element

The main indicator when choosing a material is a redstone. What it is more significant, the harder material. In the production of a metal-cutting tool, more precisely, its active part is used:

- Steel instrumental to which belongs to both carbon and alloyed, and high-speed. The tool is working when the finishes are subject to details from simple materials, while do not expect high cutting speed, it will not be possible to achieve it. The redstandiness is the lowest - from 200 to 250 degrees C.

- Solid alloys with high wear resistance. Usually they are doped with tungsten. If you compare with tool steel, then the cutting speed is capable of reaching a tool from a high hardness alloy, up to 4 times more. Collaneness in 600-620 degrees C. If high-strength or heat-resistant steel is processed, then the need for applying a metal-cutting tool with a predominance in its composition of molybdenum, vanadium, cobalt, but the percentage of tungsten is reduced. At the same time, with increasing hardness, the fragility increases. It cannot be used, performing uneven sharpening and shaped milling on a large depth.

- The cutting portion is reinforced by mineral incelamic super-harden plates. The basis of the material is aluminum oxide, which is added molybdenum and chromium. Red hardness is very high - 750-900 degrees C. However, despite the enormous hardness, ductility characteristics of this material are low, it is very fragile, can not be said about diamond and cubic boron nitride.

Manufacturers of cutting tools

Production of cutting tools, present in our market, engaged in both ours and foreign companies.

domestic

Among Russia's enterprises leading in this industry can be called Nir CJSC - Closed Joint-Stock Company "New Instrumental Solutions", which produces a monolithic tool, exclusively from solid alloys. To its benefits include:

- the presence of a special nanoclay;

- greater wear resistance;

- the ability to quickly shift the tool;

- reducing the cost per battle.

Another oldest domestic manufacturer: Moscow Instrumental Plant (MIZ). Releases a teubrous, thread-cutting and threaded tool. High accuracy is ensured. Quality is focused on world standards. Using this tool:

- cut the threads of different types;

- processed on the lathes of pipes and couplings;

- receive non-standard threads.

New offers of this manufacturer appeared on the market:

- worm cutters with a slightly enlarged active part with a reduced size of the outer diameter, which increased their durability;

- instrument with a difficult multilayer coating.

Overseas

A great cutting tool in a considerable assortment presents a company from Israel ISCAR. The sale of the ISCAR metal-cutting tool in Russia is carried out by INTEHSERVIS LLC. Acquire a tool for:

- milling;

- sharpening;

- drilling;

- also supplied metal cutting equipment.

A good tool supplies ARNO (Germany). They are treated:

- titanium;

- aluminum alloys;

- stainless steel:

- cast iron;

- steel steel having a hardness of 70 HRC.

How does Arno tool behave in work, look at this video yourself:

Good reputation and from a metal coating tool produced by the Japanese Sumitomo Corporation. They are made of:

- solid alloys;

- diamonds;

- CBN.

Application area:

- drilling-milling;

- turning.

There is always the demand for a metal-cutting tool that performs milling grooves and processing of longitudinal grooves, the German company Paul Horn GmbH is the most solid tool manufacturer in Europe. The nomenclature consists of:

- tool Super-mini boring manual with a minimum diameter of 0.2 mm;

- the tool of the boring MINI, where the removable plate has a frontal mount;

- milling tool, allowing to apply a circular interpolation method when processing grooves. Diameter, at least 0.96 cm;

- processing internal grooves. The smallest diameter is 0.3 cm;

- cutting the thread inside the holes. Diameter - minimum of 0.3 cm;

- processing grooves with a diameter of a minimum of 0.5 cm;

- cBN and PCD tool, where the basis is the boron cubic nitrate and polycrystal diamonds, respectively.