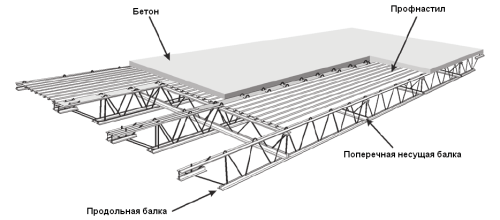

Reinforced concrete structures are used everywhere today. Concretion is widely used when the foundations are founded by various structures. In addition, it is successfully used when carrying out installation work for floors of buildings and frames. And the monolithic concrete structures were used more often. They have a number of advantages. For example, their cost is less. In addition, they can be given almost any shape and size. Often, the overlap of the monolithic sheet is used to build buildings with a metal frame. Thanks to them, the design becomes more rigid and stable.

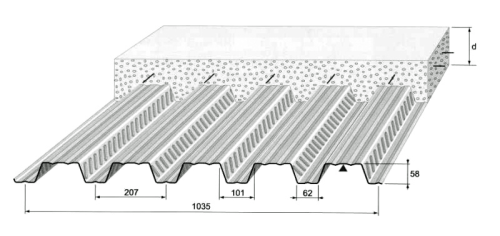

Today, a non-removable formwork has increasingly become used in concreting, made of professional flooring. This design, among other things, performs the role of external fittings. At the same time, it will partly compensate for the load on the lower reinforcement grid, which, in turn, increases not only the strength, but also the carrying ability of the overlap. In addition, the monolithic slab with a straightener has a coating that performs simultaneously a protective and decorative role, which can be avoided by spending on carrying out facing works.

Content

Calculation of overlapping for professional flooring

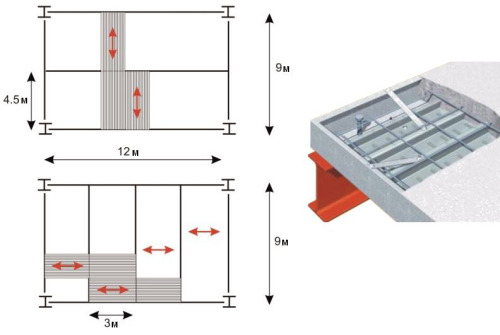

Dimensions of the formwork profile, the thickness of the overlap of the professional flooring, as well as the cross section of the metal rods depend on the load arising during operation, as well as the length of the span existing between the support beams. As for the stove thickness, it is usually determined depending on the length of the span with a ratio of 1:30.

When calculating, the sizes of the future building must be taken into account, the weight of the construction structure. In addition, it is necessary to take into account the calculated load on the overlap and the characteristics of the foundation of the most built. From these parameters, it depends on what kinds of metal beams and colors will be used.

Drawings of the monolithic overlap according to the professional flooring are performed anyway. By itself, this building construction is very important, and requires a strict compliance with safety regulations when installing strict safety regulations. Therefore, before you start basic work, you must prepare project documentation. It is usually performed by SNIP II-23-81. On it, the design is calculated.

These calculations are considered rather complicated. Therefore, a special software was developed that facilitates the calculations and allowing to create work documentation. It, in particular, includes drawings of formwork and reinforcement, as well as estimates for the purchase of materials.

At the design stage, more technical and economic calculations are performed, which allow you to determine how it is advisable to do exactly the monolithic overlap for a particular building. The fact is that its price is higher than on a monolithic reinforced concrete structure, made with a conventional formwork. It should be understood that errors in the calculations entail not only additional costs, but also can threaten the lives of people. For this reason, if you did not do such a computing, it is strictly recommended to seek help to professionals.

It is more expedient to use professional flooring for overlaps with non-standard dimensions. In such structures, there are quite a few technological openings. In this case, the individual panel formwork will be more expensive. In addition, it will not be possible to use it many times.

Work cannot be started without making sure that all the necessary calculations were fulfilled. In addition, possible loads should be defined. As a base, columns of metal and beams are usually used. Their sizes also need to be determined in advance. To do this, you need to calculate the load on the overlap. It should take into account the fact that the beam step depends on the material of the professional flooring. So, the height of the profile is greater, thedes between the beams are less than the distance. This is due to the fact that the strength of the fill with concrete will be not very high.

If all the conditions and requirements are fulfilled, then you can handle the monolithic overlap of the professional flooring. This will require only special equipment. The technique of performance cannot be called complicated. Moreover, in order to reduce the cost of their conduct, it is recommended to simply rent the necessary equipment, and not buy it.

Device of monolithic overlap

All works are quite able to make it yourself. To do this, it will be needed, as already mentioned above, prepared documentation, in particular, plans and drawings. It is necessary to follow all the requirements specified in the instructions. In general, carrying professional flooring requires a careful relationship, he does not tolerate mistakes. Overlapping under the foundation is one of the main components of the construction of any home. If the layout is incorrect, then the whole design can be unsuitable for operation. To avoid this, you need to carefully carry out all construction work. Therefore, if there is no experience, it is recommended to consult or even enlist the help of a specialist.

The main stage on the construction of reinforced concrete overlap is the fill of the formwork. When the monolithic design is ready, it can be used as a finished ceiling, without the need to carry out additional refinement and finishing work.

Another important link in monolithic overlap are profiles. They allow you to get a ribbed section. Due to the presence of edges, the reliability of the overlap becomes much higher. In addition, the costs of acquiring reinforcement and concrete mix are reduced. What in turn reduces the cost of construction as a whole.

The overlap of the professional flooring can be viewed as a formwork, just not removed. It will then be covered with a layer of concrete. At the same time, the metal frame of the overlap will perform the role of support. Such a reliable design makes it possible to use smaller materials to build walls. After all, part of the load from the overlap falls on a metal frame, which in turn reduces pressure on the walls.

Thanks to the design of the professional flooring, it is possible to use cheaper foundations during the construction, and this is one of its main advantages. In other cases, the construction of massive buildings requires a bookmark of the base of the tape type, and it will require considerable costs of installation and acquisition of building materials.

If the load is transferred to the frame, then it makes it easy easier. In these conditions, the pressure is reduced directly to the foundation itself. Therefore, it is allowed to use a cheaper option of the basis - Column. At the same time, to make such a frame, you will not need large financial costs. It will save both money and time. If a column foundation is used, we must not forget that each column is able to normally withstand pressure only for its part.

Installation of flooring from corrugated

Mounting Consider on the example under the following conditions:

- between the beams, the distance is no more than 2.5 m,

- material brand - TP-75,

- a sheet thickness is 0.9 mm.

Before calculating the required length of the professional flooring, it is important to consider that in the end he must reliably rely on three beams. Thanks to this, the sheet will not be overtaken in the future.

The sheet to the metallic base is quite difficult to attach. To do this, it is recommended to purchase a screw with an enhanced bromard. This feature allows fastening to easily go to the channel. And even if the hole was made for him. The overlap of the professional floor can be done with armor-piercing (32 fasteners).

The attachments themselves are recommended to be placed in each zone, where the professionalist has contact with the base beam. The fact is that the load on such a construction will be high enough. The joints of the joints of each of the sheets also need to be fixed with the help of smaller self-sizes. Moreover, screw them should be so that between them was the distance of about 20 mm. When the professional flooring is ready, you can begin to prepare reinforcement.

Overlapping for professional flooring: reinforcement

Armature, in fact, plays the role of a framework, thanks to which the bold concrete can withstand workers. If the formwork is fixed, the monolithic overlap will be less durable. Consequently, reinforcement must be carried out in all the rules. The bulk structure is performed from longitudinal 12-millimeter rods, which are stacked in each trades of the professional flooring. In addition, the so-called upper reinforcement is used. In this case, the longitudinal parts are made of 12 mm thick, and the transverse - from 6-millimeter routines.

Parts of the reinforcement frame between themselves are connected by welding or steel wire. The welding method is good in that the design in the end is quite durable. In addition, such a connection is pretty quickly made personally. However, it is better to use the wire. Framework framework is erected from wood. The boards themselves must be protected by film or runner.

Pouring overlap by profession

Overlap are performed from a high-class brand of concrete. To get the maximum strength, the fill must be performed at a time. Consequently, everything necessary for work should be "at hand". Concrete, mixed with her own hands, is better not to use. It is best to order ready. In addition, the Pouring will need a special equipment. In particular, concrete pump and a belt type conveyor.

After the overlap is flooded, it must be aligned. Do not forget to install several additional backups before the concrete mixture. They will help to avoid the deflection of professional flooring under the severity of the reserted mixture. These supports usually dispose directly between the beams.

When the composition gives sufficient strength, the supports are cleaned. For this, under normal conditions, at least 30 days are required. The fill should be done only if the air temperature is higher than zero. So, in 12 days, the concrete can dial up to 70% of strength. Upon other conditions, for a set of strength, concrete requires more time.

If you have to work in dry and hot weather, then in order to prevent the appearance of cracks, the compound is required to periodically moisten. If freezing may occur during work, it is recommended to book a mixture that has special additives. It can dial the necessary strength even at low temperatures. However, such funds have a fairly high cost. Therefore, to reduce costs, work on the pouring of concrete is better to spend in the last month of spring or in the summer.