The lattice flooring is a modern design material used in various fields: energy, shipbuilding, road construction, creating ventilation and water treatment systems, drill platforms, stairs, etc. Read more about what is such a lattice, what is its features and scope of application, you will learn from this article.

Content

Characteristics and positive material properties

The lattice flooring is a special metal cloth consisting of a variety of cells. Such a structure allows the material to skip water, moisture and dirt, which is why it is convenient to use such a lattice in the most unfavorable conditions. For example, if made from the flooring steps of the street ladder, in the winter time they will never form icy crust, besides, they will remain relatively clean even in the very slurted weather. To extend the life of the material, making it stronger and more resistant to moisture, manufacturers are subjected to metal galvanized.

The lattice flooring has a lot of positive qualities, we will analyze them in more detail:

- The metal grille is a non-combustible material, therefore it is considered safe in the event of a fire. In addition, the metal is environmentally friendly and safe for health.

- Due to the low weight, the lattice flooring does not have strong pressure on the designs in which it is used. Because of this feature, such material is conveniently used to create racks and shelves.

- Despite the small mass, the flooring has very high strength and is able to withstand significant loads, for example, on 1 m² of the area of \u200b\u200bthe flooring may have to 1800 kg.

- The metal grille is perfectly withstanding dynamic loads, as a result of which it does not bend and is not deformed, while maintaining its original look.

- The cellular structure misses the light, and if it is laying out of such a flooring, even the lower shelves will be sufficiently lit.

- Since the lattice flooring is made from high-strength galvanized steel, it has a sufficiently long service life. The material is not damaged to rust and does not destroy under the action of moisture.

- The lattice layer looks very aesthetic and neat.

- Details from such material are easily and quickly collected and dismantled. If for any reason the part of the design must be replaced, the desired fragment can be removed, without disassembling the entire structure.

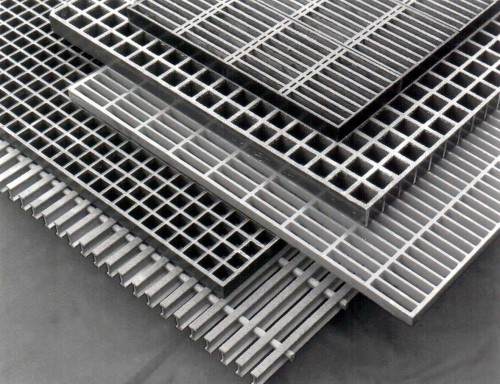

Species of the lattice galvanized flooring

There are 2 types of similar material that are classified according to the method of production: extruded and welded flooring. Consider more details of each of these species.

Pressed lattice flooring

Inexpensive, high-quality, lightweight and high-strength extruded flooring has a kind of cellular material and is made using special equipment. The process of manufacturing such a lattice lies in the fact that carriers and binding bands are interconnected by the method of cold pressing. The pressure that is used is equal to 100 tons. The extruded lattice flooring is made mainly of stainless steel, which passes the galvanization process and is as a result becoming more resistant to moisture and corrosion formation. Sometimes small carbon steel is used for the manufacture of flooring.

Since the process of production of pressed flooring allows you to create various sizes and shapes of lattice modules, such a material can be used in a wide variety of areas. Often, such a lattice is used as an anti-infamous coating in places of large cluster of people.

The price of galvanized flooring, as well as the features of its use depend on the technical characteristics and size of the web, namely, from the thickness of the bearing strips. Material manufacturers produce products of various dimensions: the minimum indicator is 500x1000 mm, and the maximum - 2400x2400 mm. Blinds the flooring and sizes of cells. Popular sizes are considered as follows: 33x33 mm, 33x11 mm, 33x16 mm and 25x25 mm.

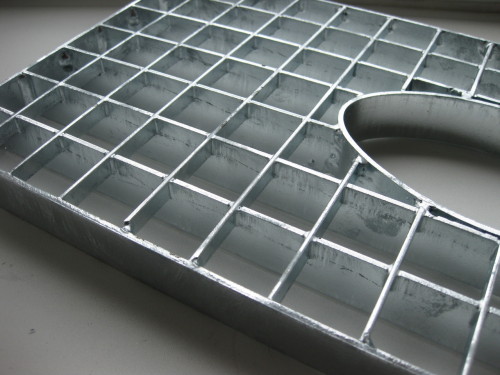

Welded lattice flooring

The second variety of material is a welded flooring, which is a metallic design of a cellular type. The base of the welded flooring is the bearing strips, which are connected to the covering rods by grasshuscular press welding. Such a lattice is sufficiently strong, it is not subject to corrosion and deformation, it looks neat and beautiful, and also easily mounted.

The welded lattice flooring SP was widely used in industry and in the household sphere. From such a material, there are steps for stairs, various bridges and transitions, shelves for racks, platforms, etc. In addition to high strength characteristics, welded flooring has an attractive appearance and a small mass. Designs made of it, not only look light and air, but also are in fact.

Welded flooring is made in different dimensions and configurations, moreover, its cells can also have different sizes. If you equip the lattice with special anti-slip teeth, the surface will not be slippery even in the conditions of ice.

A similar material is made of high-strength low-carbon steel, which is covered with a layer of hot zinc. However, there are also non-zero varieties of a welded lattice. In the production of galvanized flooring, manufacturers adhere to the requirements and standards of DIN, so products are obtained very durable, reliable and have a long service life.

Due to the fact that the welded flooring easily transfers static and dynamic loads, it is widely used in the creation of various platforms and platforms. Often, such material can be found in the industrial sphere, for example, as coating channels and communication paths. Lattices with a cell size of 30x32 mm have 780 welded connections - this is due to the high strength of the flooring and the possibility of its use even in the most unfavorable conditions.

Such products are produced in several sizes. The largest dimensions are 2500x2200 mm, and the smallest grilles have a size of 500x1000 mm. Cells in the welded flooring are also different, the most popular sizes are as follows: 34x38 mm, 34x100 mm, 34x76 mm and 34x50 mm.

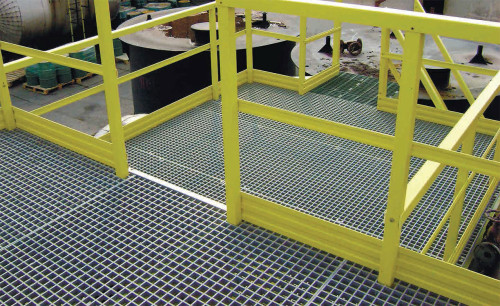

Areas of using lattice flooring

The lattice flooring can be called a universal material, since the sphere of its use is extremely wide. Such a lattice can be part of the structures located both indoors and in the open air. Thanks to the anti-corrosion properties, the flooring is not terrible precipitation, water, high humidity. Consider more in which areas can be used galvanized lattice flooring:

- The material is used to create industrial sites and pedestrian zones. For such purposes, lattices of different heights are used, which fluctuates from 20 to 40 mm. As for the sizes of the cells, it can also be different, for example, 33x33 mm, 33x36 mm, 33x11 mm and 33x22 mm. Sheets of flooring are fed up with U-shaped profile or bandage steel.

- Another area of \u200b\u200buse of the material is to create stripes for the passage of forklift trucks or cars of passenger and cargo types. In this case, the flooring is used with a cell size of 33x33 mm, which is also framed by the edge of the U-shaped profile or bandage steel. The direction of laying the lattices plays an important role in the design of such structures, because the bearing strips of the flooring should be placed across the movement of motor vehicles.

- Steps of stairs and staircases are another area where the galvanized lattice is successfully applied. Such structures can be both direct and screw types. For standard straight stages, strip steel 70x3 mm in size, equipped with bolt holes. Stairs for stairs should not be slippery, therefore, according to DIN requirements, they are focused on a special anti-slip edge. As for the screw stairs, they often perform not only practical, but also decorative functions, being the original design detail of the interior. Among other things, the screw structures allow you to save space. If you make a similar staircase from the lattice flooring, it will turn out not only beautiful and original, but also safe in operation. Galvanized flooring has an openwork, with the result that the entire design looks pretty air.

- From the lattice flooring, the panels for fences are produced, when creating bearing strips are placed in the vertical direction. Such panels around the entire perimeter have edging from a flat steel strip. On racks, elements of fences are fixed with bolts or other fasteners. Fences can have different heights, but the maximum indicator reaches the mark of 3 m. The highest width of the lattice floor panels is considered to be 2.4 m. Manufacturers deliver goods with various decorative fences, as well as with galvanized fasteners. Lattices for fences can be painted in the customer chosen by the customer. Similar structures are performed not only protective functions, but also are an element of design.

- The lattice galvanized flooring found its use as details for ceiling structures. The surface decorated with such material looks original and attractive. In addition, with the help of lattices, you can not only decorate the ceiling, but also hide various communications and wires.

- The metal flooring is quite commonly used in the production of racks and shelves. Such products have a lot of advantages: they have a small mass, easily assemble and disassembled if necessary, transmit light and provide good visibility. Among other things, the shelf from the steel lattice passes water, which can be useful if the fire occurs in the warehouse. If, for one reason or another, part of the shelving must be replaced, dismantle the selected fragment and install in its place the new will not work. Since the designs of the lattice flooring have a small weight, the racks will not create a large load on the overlap, so the designs can be made any height.

- From the galvanized flooring also produce ramps - structures designed to lift or lower the wheel transport from one level to another. Thanks to ramps, wheelchairs and baby carriages can easily call on a high curb or climb along the stairs to the front entrance of the building located on the elevation.

- The elements of galvanized lattice flooring are used in ventilation systems, filtration and water purification. For example, with the help of such a lattice, you can close the ventilation holes in the raised floor. It is used for flooring and as filtration lattices intended for delaying garbage from the flow of water. Since galvanized steel is not subject to corrosion and has good strength, it can be used for a fairly long period of time.

- If the customer needs to buy a lattice flooring a non-standard configuration or size, most manufacturers provide a service for manufacturing goods under the order.

Grid flooring, photo:

send the strength of the lattice 2 pcs 1 m per 1m

send a grain of a grate 1 met for 1met My phone 89037997411 Mikhail

And where are prices?