As a rule, the final stage of the apartment repairs is the glazing of the balcony. The advantages of the glazing balcony are obvious: an additional room appears, which can be used as a cabinet or arrange a floral greenhouse there. In addition, the apartment will be better to look from aesthetic point of view, glazing improves sound insulation, helps to save heat. But before proceeding to work, it should be sorted out when it is better to glass a balcony, what kind of frame design. These and other questions here can be found.

Content

How to make a glazing balcony. What you need to know about the types and design of balcony frames

The glazing of the balcony is performed according to one of the two options: "Cold" and "warm." In the first case, the task of protecting the balcony from the rain, snow and wind is solved. "Warm" glazing also protects from street noise, from cold and hot sunlight.

Depending on the material from which the profile is manufactured, the frames are:

- wooden;

- aluminum;

- metal plastic.

It is less commonly used in the form of a glass solid wall. Together with the advantages (high light light and originality of the appearance), such glazing has drawbacks: high cost, instability to strong wind loads. In addition, the solid walls are poorly protected by a balcony from temperature drops, since their design is monorable.

Ram classification for glazing balcony

We list the types of material for glazing the balcony, the advantages of each option and disadvantages.

- Wood frames: differ in aesthetic attractiveness and environmental friendliness. Modern products are structures from multi-layer glued wood of different breeds. In this case, the fibers of the adjacent layers are directed opposite to each other, due to which the frame is not deformed due to temperature differences and moisture changes. Wood is protected by a special impregnation, thanks to which the life of the frame is long. Glazing is performed using double glazing. Failure frames from wood - high cost.

- Frames with aluminum profiles. The metal from which such frames are manufactured is not subject to corrosion, has sufficient strength and aesthetic appeal. Their negative quality is the high heat-conductivity of the material, which is why they are more often used by structures for the "cold" glazing (with monostecl).

- Metal-plastic frames for the balcony are made by multi-chamber: within each profile - several jumpers. Due to this profiles have good thermal insulation characteristics. Strength The design is obliged to a metal insert located in the middle of the profiles. Rama color is usually white, but it may be laminating a film from PVC "under the tree" or other color.

By the method of opening and type of accessories, balcony frames are with sash:

- sliding and sliding;

- obliquely slide;

- swing (swivel-folding).

The latter can be with the impost (jumper between two sash) and without it. In order to ensure the best natural lighting in the apartment, install glazing over the entire height of the balcony - from the bottom plate to the top ("French windows").

Tip: For balcony glazing, a design with a broken central part without an impost is better. Sliding flaps may refuse to stick snow and glaciation.

Glass classification for glazing balconies

High-quality glazing of balconies involves installing frames with double-glazed windows.

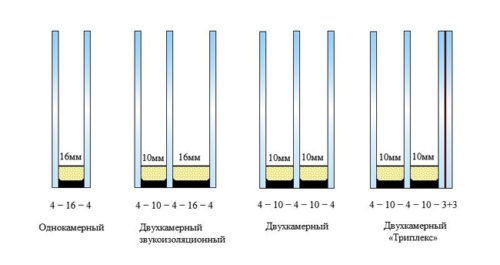

The microclimate in the room largely depends on the choice of glass packs for the frames. By the number of cameras, they are divided into:

- single-chamber;

- two-chamber;

- three-chamber.

Read more about the design of double-barakers.

- Single-chamber glass stack consists of two glasses, between which is a camera filled with air or inert gas. Accordingly, a two-chamber double-glazed glass is assembled by their three glasses, between which are two cameras, etc.

- For the manufacture of double-glazed windows, glass is used with a thickness of at least 3 mm. External glasses are usually 4 mm. The glass pack parameters indicate a set of numbers, for example: 4-10-3-16-4, where the 1st, 3rd and 5th numbers mean the thickness of the glasses, and the 2nd and 4th - the distance between them (the thickness of the chamber ).

- The energy-saving characteristics of the entire balcony glazing depend on the thickness of the glass package. This, in turn, determines the temperature at which condensate is formed on the glass.

Glass windows made of glass with various characteristics, as well as with filling the chamber inert gas (usually argon, in some cases xenon or crypton). Types of glass windows:

- sunscreen;

- structuring ("Triplex");

- tinted;

- heat-saving;

- energy saving;

- mirrored;

- noise insulating;

- patterned;

- painted;

- laminated.

Tip: For balcony frames, it is better to choose single-chamber double-glazed windows (due to less weight), but with the filling of the chamber inert gas.

Determination of the size of the balcony glazing

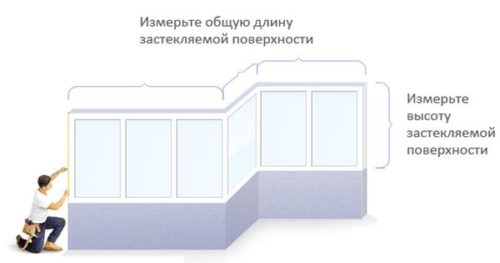

Before ordering a frame, you need to know how to remove the size of the balcony for self-glazing the balcony. At the same time, it is necessary to consider the following.

- Before removing the sizes, you should dismantle the old frame or partially release the measurement zones from all materials and fasteners.

- The opening, in which it is planned to install a balcony frame, usually improper geometric shape. There may be significant deviations from the horizontal and vertical of its respective parties. In this regard, it is necessary to remove the size in three to four places when determining heights and also - when determining the width of the opening. The final size for the frame is chosen on the basis of the smallest values \u200b\u200bobtained.

- To mount the frame in the opening, a gap of 20-30 mm is needed from each edge for the insulation of glazing. In addition, the installation of the windowsill and a standal profile should be taken into account.

- Before determining the size of glazing, you need to evaluate the state of the parapet. If necessary, it is at first strengthening.

Balcony glazing technology

After the balcony frame is made and delivered to the installation site, you should take care that the necessary tool for glazing the balcony should be taken at the disposal. It will take the following to work:

- level;

- roulette;

- hammer;

- electric drill;

- perforator;

- screwdriver.

In the event that the glazing will begin with the strengthening of the parapet, the Bulgarian and the welding machine will be required.

The priority of the performance of the glazing of the balcony is the following.

- The basis for the future balcony frame is strengthened by welding a metal frame or brick (gas block) masonry.

- The construction knife with the edge is neatly approaching and plastic strokes from the windows are removed, double-glazed windows are extracted. It is easier to install the frame in place without them, as well as drill holes for anchor screws or screws on the inside of the profile.

- The front frame of the balcony glazing is based on the basis and temporarily fixate with wooden wedges from all sides. Between the basis and the frame laid the sonological gasket. At the same time, they exhibit the frame vertically and horizontally. Using the level, check all planes from different sides to prevent deviations and distillations.

- Fasten the front frame to the base (to parapet) and to the top plate of overlapping with screws. In the event that the frame is installed on the removal structure, additional fasteners are required - plates. Distance between fasteners - 0.5 m.

- Clean temporary retainers - wooden wedges.

- Fill the mounting foam clearances around the frame perimeter.

- Install the glass windows, window fittings and closed the sash. They cannot be opened until the foam is completely free.

- Similarly, the side frames are installed and connected them with the front frame of the angular profile. Between the wall and the frame also laid sicken gaskets. Slap closes the gaps between the wall and the frame profile.

- Perform the mounting of the top visor and low tide at the bottom. Their angle of the slope should ensure the possibility of rainwater.

- From the inside, the windowsill is installed.

After that, you can proceed to the interior of the balcony. It is important to remember that this is not allowed to use combustible materials.

Glazing balcony in terms of legislation

Before starting to glazing, you need to find out when you need permission to glazing the balcony and what coordination is required to get. It is necessary to consider the following.

- In the event that the balconies in the house were not previously glazed, any change in the appearance of the building is redevelopment. This requires coordination with the relevant executive authorities.

- If the house is an architectural monument, the glazing of the balcony is prohibited by law, and for violation of this requirement it faces a fine.

- The design of the glazing creates an additional burden on the balcony slab. In this regard, an architectural project should be developed for further design in BTI.

- Plastic profile must comply with fire and sanitary safety standards.

Addition to the above information on how to glacit the balcony: video with explanations of an experienced master.