An oriented chipboard or OSB-stove is another way of intelligent application of non-glazed wood. This composite material was invented in Canada, and now it is universally in demand in construction, in the manufacture of furniture. The proposed article will introduce you to the species and characteristics of OSB, will tell about their use.

Content

A little about production

Plates are produced by the method of pressing wood waste 6-9 cm long and thickness from 0.5 to 0.7 mm of coniferous and hardwood. At the same time, coniferous apply European manufacturers, and in America and Canada - deciduous. The secretion of the OSB stove resistance lies in the fact that the inventors are located chip in 3 or 4 layers of material:

- in the upper layer, it has a longitudinal, relative to the axis of the plate, orientation;

- on average - transverse, at an angle of 90 degrees to the upper and lower layers;

- ships in the lower layer is located as in the top.

Simplified production technology looks like this:

- Form wood carpet on special presses under high pressure and at high temperature.

- Imprete for a bundle with phenol and formaldehyde resins, waxes.

- Cologain to standard sizes.

Why this material is so popular

Every year the supply of OSB plates increases due to growing demand. Why did these three-layer plates won such popularity? The answer is obvious:

- visually they are attractive;

- compared with the chipboard more than 2.5 times;

- do not smell, inside there is no emptiness, bitch, so they are also called "improved wood";

- no special tools are required, processed by easy toothed carpentry tools;

- hold nails, screws are very firmly, because The composition has adhesive supplements;

- have a small weight, so when applying for frame construction does not need a powerful foundation;

- keep strength characteristics even after a daily stay in water;

- environmentally friendly, since the percentage of formaldehyde resins in the composition is insignificant;

- have excellent heat and sound insulation properties;

- resistant to chemicals and mechanical damage;

- have antiseptic properties due to the presence of special additives;

- calculated for long-term operation.

On this list of QSB advantages does not end, such qualities can be attributed to this list:

- small tolerances;

- high density;

- ideal faces;

- uniformity properties anywhere;

- elevated fire resistance.

Types of OSB plates

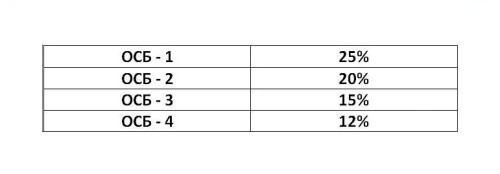

Industry manufacturing 4 types of chipboard plates:

- OSB-1 - use for the manufacture of unloaded elements of furniture, packages, plating walls indoors in conditions of reduced humidity.

- OSB-2 - Recommended for dry rooms in the manufacture of loaded structures.

- OSB-3 - withstands increased humidity and heavy loads. It is used as a base under flexible tile in frame construction, for floors and overlaps, for the device of stairs.

- OSB-4 - designs are manufactured by significant mechanical loads in combination with high humidity. Used for the manufacture of repeatedly used formwork, etc.

Color gamut plates is in the range of light yellow-brown and depends on the breed used for the manufacture, wood, pressing technology, the form applied to the ligament of the resin.

Characteristics of OSB plate

OSB plates must comply with the European standard EN-300, which puts forward the following requirements for humidity:

As for the strength characteristics, they are as follows:

From the plates given, on the OSB plate, characteristics, follows:

- OSB-4 has the greatest moisture resistance and excessive strength suitable for extreme conditions;

- OSB-3 optimal option for construction. This isb plate, the price of which is noticeably lower than the OSB-4.

Sizes of OSB plates

Industry manufacturing plates with the following dimensions:

- 122x244 cm;

- 122x366 cm;

- 125x600 cm;

- 125x250 cm;

- 125x370 cm.

It should be known that the OSB plate, the size of which is the same, can differ significantly by weight due to different thickness. Therefore, they are classified according to this parameter. It varies from 0.8 to 2.6 cm. At the same time:

- Sheets, up to 1.6 cm thick, are used mainly for cladding walls, plating floors on wood, substrate devices under a soft roof.

- Where a significant load is assumed, calculated by hundreds of kg per 1 kV. m, the thickness of the OSB plate is selected above 16 mm. Of these, the floor is laid, carrying roofing structures.

Features of processing OSB plates

When processing OSB, the same tools are used as for working with a massive tree, but should be given the advantage of carbide drills, saws, mills, nozzles. Distinctive features of working with OSB are as follows:

- Feed rate is somewhat less than used to treat natural wood.

- Fastening the sheet, when working with it, it is recommended to perform with ring and spiral nails, and smooth nails are better not to use.

- Arriving the supporting structures from the OSB should choose fasteners of a material that does not rust.

- By installing OSB, it is necessary to provide between the plates of the gaps for insurance. This will protect them from deformations when changing the surround characteristics in case the humidity changes.

Plate of OSB. Application

Such a building material, like an OSB plate, the use of which makes it easier and speeds up the implementation of many construction work, is used when they are erected:

- frame structures;

- fast-based interroom partitions;

- floor coverings;

- formwork;

- temporary buildings;

- scaffolding;

- garden houses, gazebos;

- complete bases for some roofing materials.

In addition, the plates are used for the manufacture of furniture, decorative elements of the interior.

Installation OSB is not possible without prior preparation:

- when the floor is installed, lags are installed;

- under the roof from the OSB fulfill the crate;

- when the walls are trimmed, a framework is required, for a set of which special profiles are used.

How much costs isb stove

Many factors affect the cost of OSB plates. We call the main:

- manufacturer. So, domestic plates are several times cheaper than European and American;

- brand;

- specifications.

In addition, there is a classification of OSB plates in 2 categories:

- tipped, which are mainly used for flooring;

- plates with standard edge.

Depending on which technology was manufactured by the OSB plate, the price also changes.

Overview of manufacturers OSB plates

The main volume of OSB production plates falls on the USA, Canada, European countries, but there are both domestic manufacturers whose products are presented in the wood and slab products market.

OSB from the Novovyatsky Ski Combine

This manufacturer launches OSB-3 chipboard from coniferous chips with a length of 0.6-0.9 cm. Specifications are as follows:

- Density - 700 kg per 1 cubic meter. m.

- The absence of odor of formaldehyde, which is sometimes present in low-quality products.

- Dimensions:

- 1850x2500x6;

- 1850x2500x9;

- 1850x2500x12;

- 1850x2500x18;

- 600x2500x9;

- 600x2500x12.

OSB from Hillman.

Another domestic manufacturer - Hillman Co., Ltd. Products of this company refers to premium class. The feature of the plates is that a large chips of birch used for their production. It allowed:

- achieve high physicomechanical indicators;

- get a certificate for compliance with plates by European standards.

OSB-3 plate size:

- width - 1.25 m;

- length - 2.5 m;

- thickness - 0.9 cm.

Manufacturer Norbord (Norbord) from Canada

Plates measuring 2.44x1.22 m, which produces a Canadian Norbord manufacturer from coniferous wood, differ:

- minimal moisture absorption;

- maximum rigidity;

- resistant to different atmospheric effects.

Their cost, of course, is higher than the OSB from Russian manufacturers.

Flat chip-oriented stove from Krono Swiss Group

The Krono Group of Companies unites European manufacturers such as KronoSpan, Kronopol, Kronosta and is running Kronotex GmbH. Enterprises are located in Bulgaria, the Czech Republic, Romania, Lithuania, Poland. German specialists strictly follow that European standards are respected in these countries, therefore:

- plate quality complies with EN 300 "OSB" standard;

- OSB has a stable geometry;

- the condition of the surface of the plates is closer to the piston;

- given a guarantee for 25 years.

Standard slab size from these companies - 2.5x1.25 m.

Consmos Osb Plate from China

The construction market often meet OSB plates from Chinese manufacturers. The most popular among them plates with CONSMOS marking. They differ:

- very democratic price;

- acceptable quality;

- wide selection of various varieties.

Leaf dimensions are as follows:

- thickness - 6, 8, 9, 10, 11, 12, 15, 18, 21, 22, 25-30 mm;

- dimensions - 1220 × 2440 mm / 1250 × 2500 mm.

As can be seen from the foregoing, the plates are oriented-shake - the material is reliable, durable, lightweight, many times cheaper than natural wood, so the demand for it will only increase.

About where the base plate is used, video with specific examples: