If you like to engage in construction and own the dacha, then sooner or later the question arises about the purchase of pipe-bend. This mechanism allows you to bend profile pipes under the desired angle and do it without the slightest errors. Why do you need pipes in the country? Of them are building frames for greenhouses and arbors, as well as other useful facilities. But buying a device for flexing pipes is quite consistent, so hard-working owners immediately comes to mind: "Why not make it with your own hands?". In this article we will speak just on this topic and tell in all details how to make pipe bender for the profile pipe.

Content

Device and principle of operation

Pipe bender is a special mechanical machine, invented for working with metal products. It makes it possible to beautifully and quickly bend profile and ordinary pipes on the installed radius.

The need for bent pipes occurs when installing heating systems, water supply, manufacturing of all kinds of frames, details of complex forms and other construction needs. The most common example is the greenhouse or arrangement of the veranda in the country. Working manually, it is absolutely impossible to control the bending radius of the pipe. The pipe bender bends in accordance with the specified settings and has a uniform force, which leads to the preservation of the strength and durability of the metal. The profile pipe bend is easy, but if you do it about the knee, you just spoil the product.

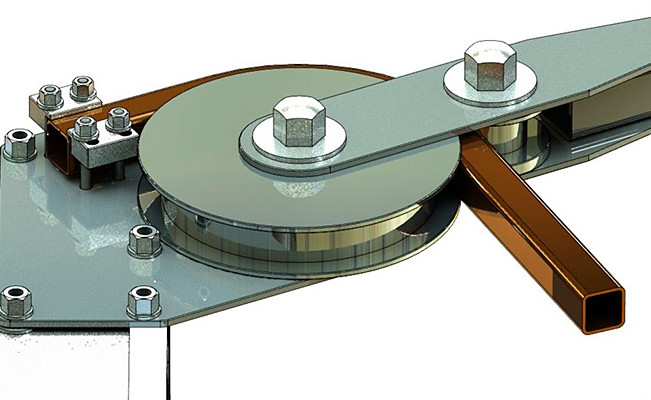

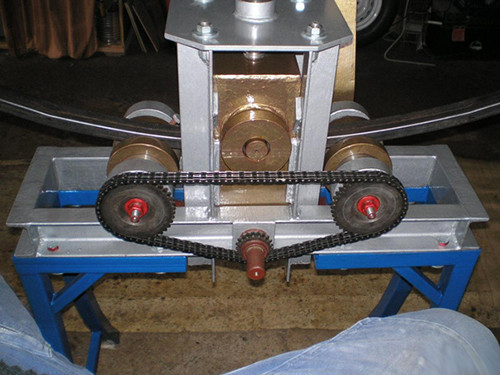

The most common variety is a trilding hand-made profile pipe bender. It consists of several rollers located in the form of an equilibried triangle. The width of these rollers is equal to or exceeds the cross section of the workpiece of the metal blank. They are connected to each other at the base of the chain drive. Located at the top of the triangle, the roller communicates with a screw clip or press and can move vertically back and forth. The workpiece is placed on two rollers at the base of the triangle and tightly press the top, then turn the winch knob and stretch the pipe. After it goes through the mechanism for the first time, the wizard slightly twists the clamping screw and again drives the workpiece through the pipe bending, and the bending radius decreases. The cycle is repeated until the pipe acquires the desired form.

The manufacture and principle of work of the profile tube - in the video below:

In simple disposable structures, the bend is obtained using rods recorded on the side of metal or wood. The pipe is bend at a time, attaching only the power of their own hands, and pamal on the bed control the radius. The bed is usually made from a wooden pallet, a concrete or metal plate or just a smooth area of \u200b\u200bland in which the rods are driven. Of course, it is not necessary to talk about the high quality of the bent item in this case, since in most cases the profile tube "wrinkles".

Varieties of mechanisms

The choice of pipe bending for the profile pipe for the most part depends on which the pipe itself is made and for what purposes it must be bent. So, for plumbing works in an apartment or private house, not only metal-plastic, but also metal pipes may be needed. Then preference is worth paying pipe bending for steel products. For cold flexing seamless pipes, use profile pipe bending, and for copper - pipe bender with a manual drive for flexible products. The latter is not suitable for pipes from steel, since copper is softer and plastic material.

Depending on the method of work, the following mechanisms distinguish:

- The arbal type - in the role of the bending part protrudes the form with a given diameter.

- Spring with manual drive - created for metal-plastic pipes and affect the material with powerful springs.

- Segmented - in these structures, the bending occurs due to the turnover of the pipe around a certain segment.

- Dornish - use to work with thin-walled pipes that need to be bent on a small radius. Dorn can be made of brass, plastic or steel.

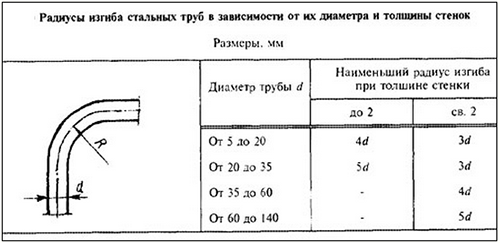

Products with different diameters, thick and composition have personal possible bending radii, which should be taken into account during operation. You can get acquainted with the allowable radius in relevant reference books. If you do not comply with these rules, not only the quality of the bend can suffer, but also the operational characteristics of the pipe itself.

Production of pipe-bend

It seems that bend the pipe is very simple, but in fact everything turns out exactly the opposite. If you misunderstand the instrument, curvature, cracks, wrinkles arise, the pipe loses its qualitative characteristics. In this chapter, we will tell you how to make profile pipe bending with your own hands and discuss several design options.

The simplest pipe bending

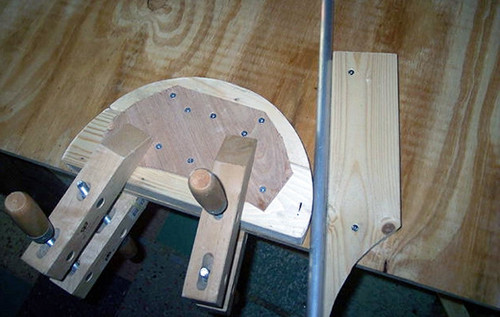

It is easiest to bend a metal or metal-plastic pipe using a predetermined pattern. It is worth noting that the method described below is applicable to bending not only aluminum, but also durable steel pipes.

To make a scheme of profile tube and make a pattern, take wooden boards from a durable wood (beech, birch). The thickness of the boards should be a little more diameter of the pipe that you need to bend. To fix the pipe on the template during the work, cut the boards with a slight inclination inside.

Create the boards with each other and fix on a flat static surface. This can be a table or any other base, on which in addition to the template itself, you can fix the flexible to hold the flexible pipe. Such a simple way you managed to make the simplest pipe bender.

Now you can proceed to work - insert the end of the pipe between the attached pattern and the thrust part. Grab the pipe for the opposite edge and smooth, but bend it with strong movements. This process can be made easier by using a lever. As a lever, you can apply an ordinary reinforcement rod - just insert it into the pipe and pull.

Important moment: Do not attempt to bend the pipe along the central part of the template. First, it is more difficult to do. Secondly, the pipe can burst.

In the same way, the principle can be done not wooden, but a metal hook pattern. Secure them on a piece of plywood, placing the desired bend line. This design has one important advantage - you can adjust the bend line by rearning hooks from place to place.

With the help of such a simple pipe bending, you can bend even thick-walled products, but in this case it will be necessary to make a lot of effort or use the manual winch.

To make pipe bender for thick-walled products, the beep does not need to do. Fixation will be carried out by installing several limiters.

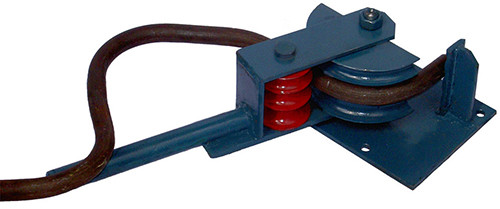

Many masters operate here such pipe bends:

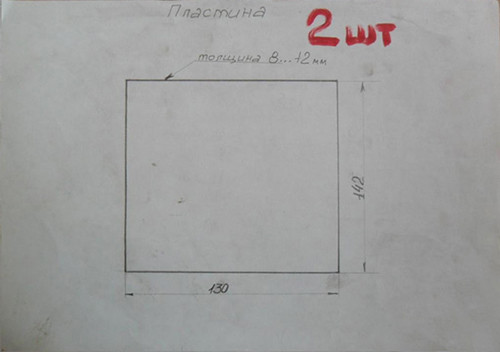

Such a mechanism can be made personally. The most difficult thing in this business is to choose correctly and make templates and roller parts, since the quality of the bend is directly dependent on the pipe diameter. If you need homemade profile tube for flexible products, then instead of steel rollers and template you can use wooden. To do this, it is better to choose solid rocks - oak, birch, beech, ash.

If the roller is metallic, it is pulled out on the lathe if wooden - cut out the jigsaw. In the latter case, you need to cut the circles with a different diameter and a mock from plywood, and then copold them with each other with high strength glue. Ski will play the role of thread. Treat the detail of the sandpaper and strengthen with metal plates from the ends.

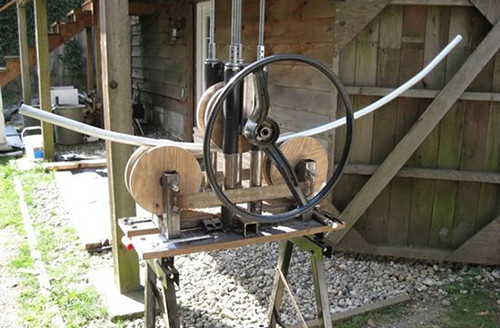

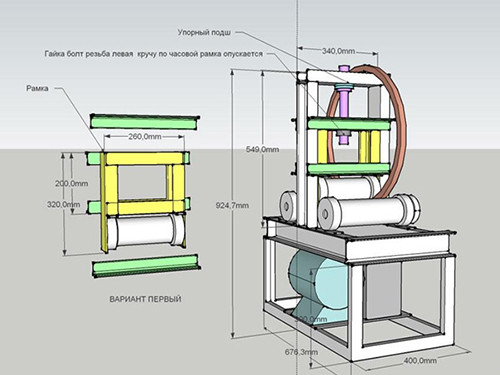

If you need to bend pipes under a large radius, it is advisable to use rolling pipe bending. Technically, their design is extremely complicated than that of the mechanism described above. In fact, the complexity of the design of the pipe-bending depends on the material from which the pipes are made - than it is stronger, the more difficult the device will be.

Rolling tube

If you plan to work with thin-walled or flexible pipes, then all the main details (template and rollers) can be cut on a lathe of wood. Thus, the cost of the mechanism and the complexity of its assembly will be minimal.

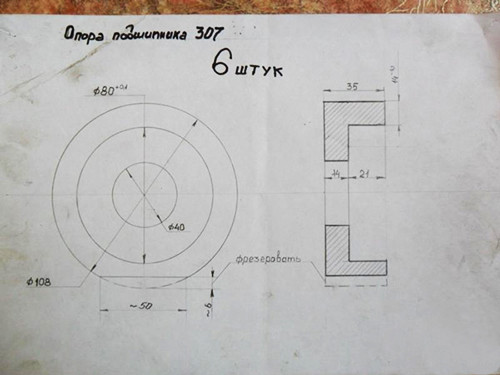

The most responsible task is to make closures for bearings and rollers. If you do not have experience and equipment for such work, order these details in the locksmith workshop. The size of the shaft depends on the stars and bearings. You can not use the first at all by creating a single-olive drive, but in this case the risk is the risk that the design will slip. Instead of a presser screw, you can use the usual car jack.

Important moment: The distance between the rollers determines the effort that must be applied to flexing the pipe, as well as the radius of its bend. The larger the distance, the less strength it is necessary to bend and drive the pipe through the mechanism, but the minimum bending radius is larger, the raw area at the end of the pipe is longer, as well as the course of the presser roller. To make the machine more versatile, it is possible at the drawing stage to adjust the size of the profile tube and set several positions of the lower rollers.

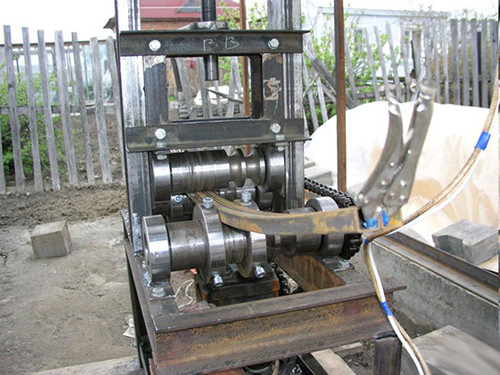

Highlights of manufacturing machine for flexible pipes:

- Bearings will suit the most ordinary, but it is better to purchase self-centered with supports. They are not very expensive, but the quality is much better. The gears and chain should also be the corresponding class.

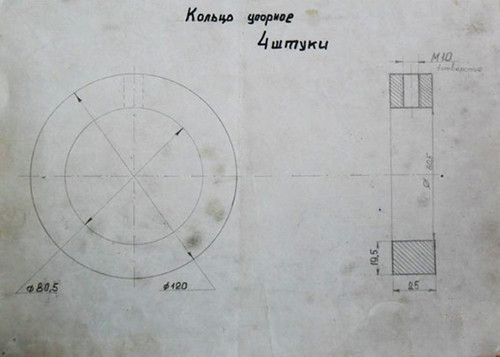

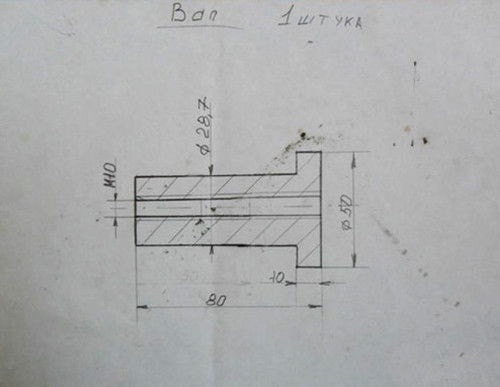

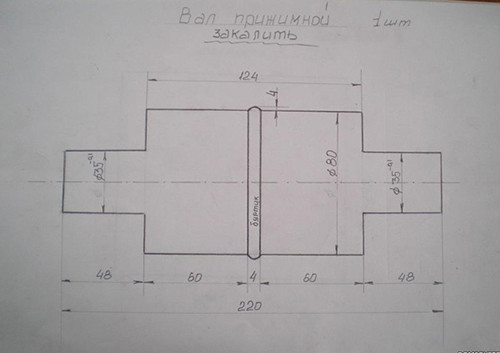

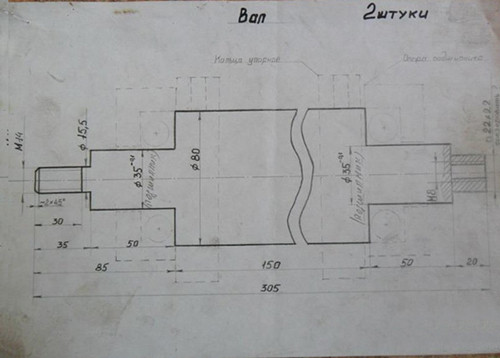

- In the turning workshop, you can order the necessary details according to the drawing of the profile tube.

- Gears will be secured through the key. Drill holes in rings and threads to ensure reliable fixation. Make grooves for the key to secure the gear.

- Remove the holes in the limit rings and make a thread under the protracted bolts.

- Spill part of the channel under the presser shaft.

- Cut one shelf so that it does not interfere with the attachment of the jack.

- Remove the holes and make a thread for fastening bearings.

- Collect the design together and ahead of the "Feet" machine with the help of a welding machine.

- Screw the pressure shaft, adjust its position and breed the nut for the springs.

- Slip the pad to the springs. The top stop at the same time to attach the bolts to make it easier to dismantle the pressure shaft if necessary.

- Make holes and screw the lower shafts.

- Build a chain tensioner. Holding can be made from a magnetic corner.

- Screw the sprocket, after inserting the key. They can be ordered in the engraved workshop. Secure the chain tensioner.

- Do not do the knob to rotate with a spinning handle, otherwise immediately wearing corn. We weld a couple of bolts to the body and install the jack on the site.

- Now you can proceed to testing self-made manual pipe bending for the profile pipe. If you are all done correctly, then the bend will be smooth and without jammed "wrinkles" on the arc.

- It remains only to cover all metal parts by anti-corrosion composition, paint or enamel.

Moistling profile pipe bender with your own hands, you not only significantly speed up the process of building metal structures or assembly of the pipeline, but also significantly reduce the cost of this procedure. Such a solution will like the hardworking and economical owners.

Profile pipe bender: photo

On the images below you will find the drawings of the rolling tube.

More advanced model:

Much of this is quite difficult to get, compressors for examples always took in pneumatic engineering