The roofs covered with metal tiles can be seen in any city and suburb. This is a popular building material that has deserved a reputation as high quality, durable and relatively inexpensive roofing. However, if you want to save on the services of specialists and carry out work on the installation of metal tiles on the roof yourself, it is necessary to carefully study the material and technology. Only in this case we can talk about a long service life and quality of the coating.

Content

Product specifications

Metal tile is inexpensive and versatile material. It can be used with the same success to build cold and insulated roofs of residential buildings and technical buildings. There are many varieties of metal tile, differing from each other with dimensions, forms and structure, not to mention the performance characteristics.

Before you go to the metal supplies for purchases, you should thoroughly study the subject of the survey to understand which grade metal tile is needed specifically in your case. At first glance, it seems that the material does not constitute anything complex - a regular sheet of metal - however, it turns out that the metal tile profile consists of a plurality of layers. The basis is a sheet metal with a thickness of 4-5 mm. On both sides, it is covered with corrosion-protecting galvania. From the outdoor side of the sheet they apply a primer that increases adhesion, after which the surface is covered with a plastic protective-decorative composition of a certain color. From the back side, a special aluminum passivating spraying is applied on top of the galvanized, after which they are covered with primer and protective varnish. The result is a high-strength resistant to moisture and temperature drops of the product. To mount the roof of metal tile, it is necessary to pay special attention to the protective and decorative coating. It can be made of various materials, excellent properties and marking.

The finish coating of metal tile can be from:

- Polyester (re) - is a polymer dye that gives a brilliant glossy surface. Is the cheapest of all coatings. The advantages include high resistance to ultraviolet radiation, but the coating is rather unstable poorly tolerate mechanical damage and strong temperature differences.

- Matte polyester (Rem) is a polymer-based dye with the addition of teflon and additional protection of the lacquer layer. This provides high resistance to mechanical and atmospheric influences.

- Polar (PU) is a polyurethane substance with the addition of polyamide. This coating is not terrible temperature differences and mechanical damage. Working with him is very simple and fast, but the cost is quite high.

- Plaserisol (PVC) - in the people such a coating is called PVC. Gives a plastic surface that are not terrible heavy loads and mechanical damage. However, the plastisol has one serious drawback - the color quickly burns under the sunny rays, so if you want to stay on this cover, you should not buy metal tile of saturated shades.

- PVF2 (PVDF) is a polymer-acrylic mixture, which gives a high-strength atmospheric coating that allows the use of metal tile on industrial facilities. However, due to fairly high cost in private residential construction, it is rarely applied.

The most problematic situations during installation and calculation of the roof of metal tiles are related to its finishing coating. Very often before the installation on the roof it is scratched, it is cleared, peeling, etc. Any mechanical damage will inevitably lead to rapid corrosion, so you should not leave even small scratches without attention. In the process of transportation, loading, unloading, raising metal tiles to top of the sheets can bend. If the finish coating is cheap or poor-quality, it is quite capable of peeling. Very undesirable to curb large sheets with a small thickness, otherwise he will not be able to lie tightly on the crate.

To avoid all these troubles, follow the simple rules for handling metal tile:

- Transfer the material, holding the longitudinal edges and protecting the hands from sharp edges with dense textile mittens.

- Do not delete the factory package until the installation.

- Raise sheets on the roof very carefully.

- Do not allow metal tile contacts with sharp objects.

- If after buying the tile will be stored for more than a month, put each sheet with boards or wooden bars. Do not store material vertically!

- Do not put anything on sheets - grazing and point loads will lead to deformation.

Mounting technology of the roof of metal tile

Before you begin the description of the installation instructions for the installation of the roof of metal tile, it is worth talking about how to make calculations. This will prepare the desired amount of material and fasteners.

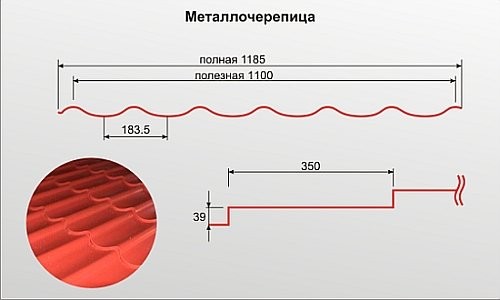

The most comfortable and visual way will make the image of the roof on the scale and "impose" metal tile on it. If you have the skills of working in editors, make a circuit of installing the roof of the metal tile is even easier. But for a more accurate calculation, it is better to resort to old-good geometry, separating the largest length of the sheet used on its working width (the worker means without taking into account the docking adhesive). The resulting value needs to be rounded in a large direction (calculation horizontally skate).

To calculate how many sheets will be required for one row, measure the length of the slope from the top edge of the roof to the bottom, while consider that it is necessary to take about 50 cm. The vertical sheets will go to the row. If the lengths of the sheets are enough to block the whole range, it is not necessary to take into account the nestling. Summarize all the obtained indicators and get the required length.

Useful information: often manufacturers cut the sheets according to individual standards. In such cases, the calculation of metal tiles should be engaged in their representatives. The length of the sheets can vary up to 70 cm to 12 m, but it is most convenient to work with 4-4.5 m products.

Features of laying and fastening the roof

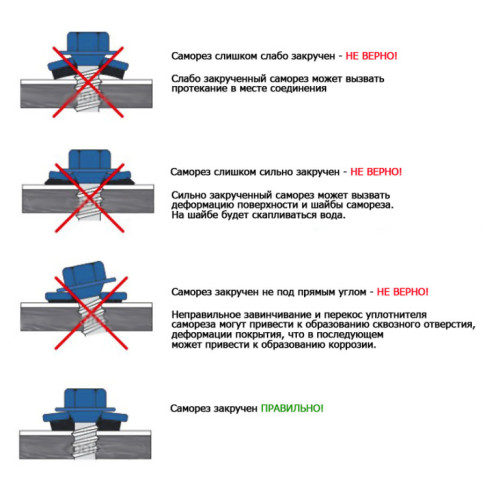

The roof and between the metal tile is mounted with standard 4.8x28 mm sammers with gaskets. On 1 m² of the surface should have about 8 pcs. It is very important to correctly calculate the strength of screwing the fasteners. They should stand strictly vertically and enter through metal tile in the crate to minor flexing of the gasket. If you screw the scout or override, the metal tile is deformed. After installing each self-press, it is necessary to remove the metal chips with a soft brush so that it subsequently scratched the surface. You need to screw in the deepening between the two "waves" of the tiles, retreating about 1 cm from the stamping line.

For the manufacture of crates for metal tile, they use equal in width and thickness of the board, attaching them to the frame at a distance on which fasteners will be mounted. Skating and cornice boards can be slightly thicker and have another setting step. As a rule, a carnice board for 10-15 mm is thicker than the rest.

Sequence of installation of the roof metal tile:

- Connect the "Waves" sheets to create protection from the lateral gusts of the wind. Self-tapping screws at the same time bring the top sheet wave crest.

- The first to fix the longitudinal joints.

- Docine sheets around the rows, screwing up each wave to the crate.

- On the edge of the carnis, metal tile can be attached differently depending on the contrarous features of the roof and the presence of drainage. If there is a chute on the roof, the sheets need to be pulled out by 5-7 cm and screw the screws for 5 cm above the stamping line through the wave. If the geometry of the roof is non-standard or costs a stepped cornice, the water will first flush on the cornice bar, and then go to the chute. In this case, the topboard of the crate will serve as a support for the ski board. It should be on a centimeter thicker than other boards to stay a small air gap. Self-tapping screws are installed every 80 cm, attracting the skate bar to the metal tile and screwing them into the ridges.

- At the ends of the skates fastened through the "wave".

- Face planks are fixed in the ridges, attaching to the frontal board.

Video Instructions for mounting the roof of metal tile will allow to better understand the above information:

Noise isolation of the roof of metal tile

One of the main deficiencies of metal tile as roofing material is the absence of any noise insulation. Blowing droplets of rain or hail, knocking of birds of birds or the branches of the tree branches will be clearly audible inside the house. If you do the installation of a cold roof from metal tile, prepare for such inconveniences. The work will cost cheaper, but a relaxing holiday in the summer house can be disturbed by a sudden noisy thunderstorm.

However, the noise level may be different depending on the correctness of the roofing coating. Most of the problems with noise insulation arises precisely because of non-compliance with the installation technology.

Why make noise metal roofing:

- Incorrect installation of crates from boards of different thickness and widths, resulting in areas where the tile is seated.

- Sheets are not fixed sufficiently hard or for fixing too few screws were used, as a result of which vibrate and clap from the gusts of the wind.

- Too small roof slope - the less the angle of inclination, the higher the noise level.

How to eliminate noise:

- Increasing the coating rigidity by properly fixing sheets to the crate.

- Increase the number of self-tapping screws (8 pieces / 1 m²).

- The correct installation of the rafter system in 80-110 cm increments.

- Alteration of crates using elements of equal width and thickness.

But even if the income and fastening of the metal tile is perfect, it will not be possible to avoid the appearance of noise due to the characteristics of the material itself. The metal surface in any case will resonate and rattle, but the installation of the warmed roof from the metal tile can solve the problem of noise, and the problem of heat loss. This option is suitable for residential buildings and warm business buildings, for example, the most for animals and birds.

For noise and thermal insulation of such roofs, it is used inexpensive and practical mineral wool. It is sold in rolls or plates (the plates are more expensive, but it is more convenient to work with them). As a noise absorber, any materials with sound absorption coefficient of 0.4 can be used. At the Minvata, it is 0.7-0.95 depending on the thickness. This is due to a special structure - mineral fibers are located in chaotic order, while between them there is some space filled with air. The material is quite elastic and perfectly opposed to sound vibrations.

How to properly do the sound insulation of a metal tire roof:

- Along the rafter, put the waterproofing material by fixing it with the help of a construction stapler. As a waterproofing, you can use a thick building film or a thin runner.

- Make a wooden crate and attach mineral wool to it. To improve the heat and noise insulating characteristics of the roof, you can lay cotton in two layers with sutures.

- For noise insulation, mineral wool should be labeled between rafters. Insulation layers need to be cut so that they are a little more than the size of the place where they need to be squeezed. Material elastic, so do not be afraid to make efforts to bind it between the rafters. So that the reservoir does not squeeze, first insert it in the opening between the middle rafters, and then press the edge, moving from the center.

Noise isolation is an integral part of roofing pie if the use of metal tiles is planned. The installation itself is roofing, as you can make sure it is not so complicated. The main thing is to carefully handle the material during transportation and unloading, and correctly screw the screws with compression beds. Also, do not forget about the safety of safety when performing high-altitude work.

Finally, we suggest familiarizing yourself with another useful video about the installation of the roof of metal tile: