Installation of the heating system is one of the most important stages of the construction of each house. From how correctly the elements of the system elements will be made and installation works are made, not only heat in the house, but also the consumption of energy carriers. One of the main components of the heating system are pipes. It is they carry the coolant from the heating device to radiators. Reliability and durability of pipes - a guarantee of good heating in the house.

Content

If a couple of decades ago, there were no alternatives to steel pipes, then both metal-plastic and plastic (polypropylene) pipes are currently widely used. Both the first and the second are substantially reduced and facilitates the installation process of the entire system, thanks to the absence of the need for welding. On how to carry out the installation of heating from polypropylene pipes with their own hands, let's tell later in the article.

Advantages and disadvantages of polypropylene pipes

Speaking about the advantages and disadvantages of polypropylene pipes, it is customary to compare them with metal-plastic. Steel pipes, even stainless steel are now used extremely rare, due to their high cost, installation complexity and short-life. That is why now the heating system is mounted on the basis of plastic or metal-plastic pipes.

The advantages of the heating system from polypropylene:

- Cheap fittings. Connecting fittings for plastic pipes are made from the same polypropylene, so they cost much cheaper than fittings for metal-plastic pipes made from brass.

- The soldered connection is made monolithic. Simple words, a soldered corner or a tee becomes a continuation of the polypropylene tube, which is the key to a solid compound. The disadvantage of mechanical fittings is that, when heated and cooled, the metal is respectively expanding and compressed that over time leads to a weakening of the compound and the flow of moisture from the system. Pour a couple of times a year all nuts in a big house - the lesson is not pleasant.

Disadvantages of polypropylene products:

- The polypropylene tube cannot bend. If the metal-plastic pipe can be beaten almost at any angle, then no special corners do not do.

- The process of soldering must be carried out very carefully. The pipe of each diameter is heated only for a strictly specified time. Overheating or insufficient heating can affect the quality of the connection and its reliability.

- For the installation of polypropylene pipes require a special soldering iron. It is not too expensive, but it's not worth buying it for one-time use, it is better to rent it.

Types of polypropylene pipes for heating system

Contrary to the existing opinion, not all plastic pipes can be used for the heating system. Before making the purchase of pipes, you need to know which marking on them is applied and what it means.

- PN10 pipes. These are thin-walled pipes, the work of which is calculated for the maximum pressure of 10 atm.

- PN16 pipes. Have a working pressure up to 16 atmospheres. Typically, the thickness of the walls of such a pipe is 3.2 mm, and it can withstand the temperature of the coolant at level to + 85⁰s.

- PN20 pipes. Have nominal pressure up to 20 atm.

All of the above pipes are used exclusively for cold water supply. The fact is that they have a high linear expansion coefficient. With constant heating, such a pipe can be fastened and change the form.

For heating only reinforced pipes are applied. The reinforcing layer is made of foil or fiberglass. Due to this, they withstand the temperature of the heating over + 95⁰s.

The most optimal for heating is the pipe PN25 reinforced foil. Such a pipe withstands pressure up to 25 atm, and is able to work for a long time with a temperature of up to 100 ° C.

Typically, the labeling of the pipe is as follows:

- PPR-GF PN 25 25 × 2 Class XXXXX TU Xxxxxxx.

- PPR-GF means that the pipe is made of copolymer random. This is the most popular material for heating and hot water pipes.

- PN 25 - nominal pressure for the operation of this pipe. It is believed that at such pressure the pipe should be over 50 years old.

- 25 - the inner diameter of the pipe in mm.

- 4.2 - wall thickness in mm.

Next should indicate the class of pipes and technical documentation for its manufacture.

Fittings for mounting the heating system based on polypropylene pipes

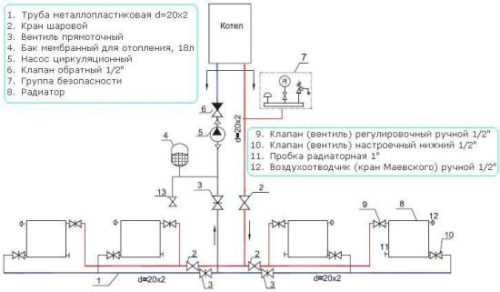

For mounting the heating system based on polypropylene pipes, the following products are used:

- Couplings. Couplings are: direct, transitional, with steel threads (both internal and outdoor). They are designed both to connect pipes by soldering, and for attaching to polypropylene pipes of steel or metal-plastic. They are also suitable for connecting shut-off valves and heating devices.

- Transient couplings.

- Cranes and valves. It is also like metal threads and without them. They are installed on heating devices, as well as trunk contours so that it is possible to turn them off for repairs and prophylactically work.

- Cross and tees. Similarly, like clutches, may have a soldered or combined compound thread. Required for connecting multiple pipes.

- Corners. Used to connect pipes at right angles.

- Plugs. Used to close temporarily unused compounds.

Before you start buying fittings, you need to draw the drawing of the entire system with the designation of all its elements, their size, diameters. Only in this case can be accurately determined how many and what connections you need to buy.

Types of mounting of the heating systems of the private house are:

- Single-mounted system. In such a layout, all radiators are connected in series. In this case, the total length of the pipe length and the number of connecting elements must be minimal. In such a system there is one big drawback - the further "pipe" the radiator is installed, the less it will be heated. Therefore, in the house heating the rooms will be uneven.

- Double-circuit. This system is the most popular. Each radiator connects to two circuits: "Feed" and "Fitting". Thanks to the parallel connection, each of the radiators has the same heating temperature.

- Multi-mounted. With this system, the room has several heating circuits that are connected using a heating manifold. With such a system, it is possible to adjust the flow of the coolant to each contour, due to which it is possible to use the energy resources more optimally. This system requires a large number of pipes and connections.

- Experts should be engaged in the design of heating systems for a private house. Otherwise, the likelihood of building a system that will not respond to the requirements of heated premises are high.

Polypropylene pipe soldering

Before starting work, you need to prepare tools and equipment necessary for installation.

- For soldering of polypropylene pipes use a special soldering iron. Its design is made in such a way as to simultaneously heat the inside of one element and the outside of the other. For each of the diameters of pipes in a set of soldering iron, there are nozzles. Each device is equipped with a power regulator, thanks to which you can adjust the heating temperature.

- Also need a sharp knife, and tools for stripping pipes that are reinforced by foil.

- The soldering time depends on the diameter of the pipes and ambient temperature. Cut pipes can not. Otherwise, the melted polypropylene will create a natural blocking of the flow of water at the junction site. So for a pipe with a diameter of 20 mm, the heating time is only 5 seconds, while the pipe with a diameter of 75 mm must be heated for about 30 seconds.

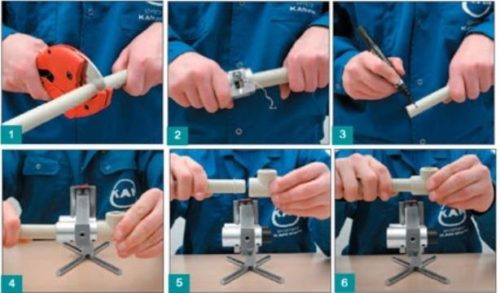

The process of soldering pipes is pretty simple:

- The first thing on the heating part of the soldering iron dresses nozzles that correspond to the diameter of soldered pipes.

- Then the soldering iron turns on the power that corresponds to the recommended pipe type.

- Two details are dressed on the nozzles (one outside, the other inside) and the necessary time is withstanding. In the process of dressing (stretching) connected parts to the nozzle, there is an influx on the surface of the polypropylene, which plays the role of the side.

- After a certain time, the parts are removed from the soldering iron and are connected to each other. In order for polypropylene frozen, it is necessary to hold them for 30 seconds.

- It must be remembered that when heated or connected, it is impossible to rotate the parts. Otherwise, polypropylene "eats" and the connection can be not hermetic. This is the main rule of installation of plastic pipes.

- Currently, the manufacturers of nozzles made a special mandrel, which signals that it is time to stop heating. It simply made a small hole. When polypropylene is already heated, it begins to flow through the hole. In this case, the details are removed from the soldering iron. Thus, absolutely all polypropylene pipes, including heating pipes, are soldered.

Useful tips on soldering polypropylene heating pipes

Important tips and recommendations that should be followed by:

- With a through passage of the pipeline through the wall, it is necessary to provide for the presence of steel sleeves. They will protect polypropylene from mechanical damage.

- In direct areas of pipelines, more than 5 meters long need to provide compensators.

- When soldering shut-off cranes and valves, it is necessary to think over their position in advance so that they have a free and complete move. This is a very widespread newcomer error.

- We should not forget about the brackets-clips that will support the sword pipes. They should be installed in advance.

- If there is no confidence as a welded seam, it is better to cut it off and remake. Work at the ready system in the case of leaks will be problematic.

- When docking the heated elements, it is necessary to take into account the docking marks on the details. You can adjust their position after a compound by 1-2 mm.