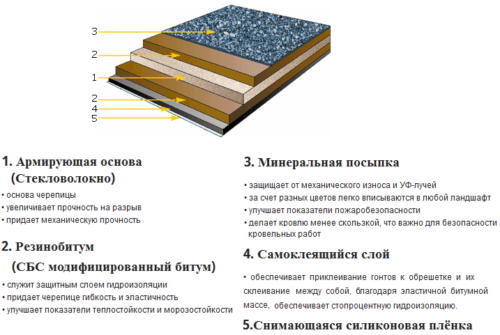

The term "soft roof" combines several types of roofing materials that differ in composition, form and method of installation. Most of these coatings are made of glass cholester, impregnated with bitumen. The top layer is a mineral crumb needed to protect against mechanical damage and sun rays. The bottom is a special adhesive bitumen, closed by a safety film or silicon sand. About how to properly cover the roof of soft roof, the nuances of performance of work - in the materials of this article.

Content

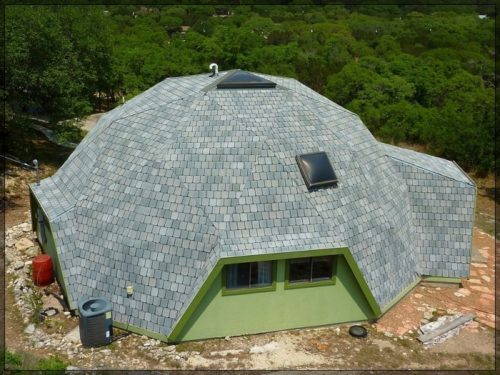

Basic information about soft roofs

To make the right choice, it should be first to study the species of the soft roof, the advantages and disadvantages of materials. Distinguish the following types of materials:

- Rolled: There are undoubted (bizol, isol) and with the basis. The first are panels manufactured from filler and additives (plasticizers). Materials with the basis (rubberoid, linocur, uniflex) is a fiberglass impregnated with bitumen and a roofing cardboard.

- Polymer membranes: also shipped in rolls. The material is based on a reinforcing mesh impregnated with a polymer (usually polyvinyl chloride).

- Bituminous tile: its elements are essentially sliced \u200b\u200bon the rowed parts. The kit is the shaped parts necessary for the roofing device of various configurations.

Features of the soft roof, the composition and technical characteristics give reason to prefer this material to others. Pros and cons of use of a soft roof (at the beginning of the pros):

- flexibility, elasticity, allowing to carry out the installation of roofing complex coatings;

- lack of waste: Rolled materials are cut in size, and bitumen tiles is consumed rationally, due to the small size of the elements;

- the ability to complete installation alone;

- the ability to operate in a wide temperature range (from -45 to +110 ° C);

- simplicity laying;

- good soundproofing characteristics;

- aesthetic attractiveness of bituminous tiles;

- dielectric properties, thanks to which you can not fear in the roof of lightning.

The minuses of the soft roof refers:

- low mechanical strength;

- the need to use open fire when installing and repairing;

- significant number of butt seams.

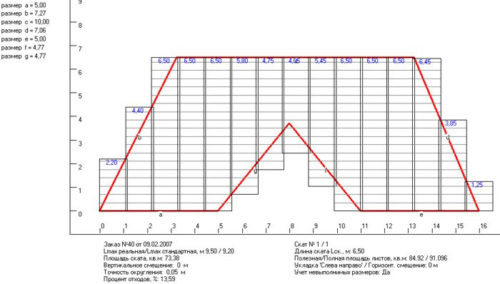

Calculate the costs of soft roof

To know how many and what materials it is necessary to work, it is necessary to make calculations. The calculation algorithm is as follows:

- Determine the roof area. Rectangular does not cause difficulties. For the roof of a complex form, a breakdown is required for individual figures, the area of \u200b\u200bwhich is calculated according to the rules of geometry. Folding all the squares, we get a general result. It is necessary to add 3% to it to obtain the amount of roofing material that should be purchased.

- We measure the length of the cornese swells and the skate bar. It is necessary to know the amount of flexible tiles of a special form. Metal strips are purchased on the same size.

- Calculate the number of consumables. We will need nails (for tile), glue or bitumen mastic. The number of nails (in kg) is defined as the result of dividing the area of \u200b\u200bthe roof at 10. The bitumen and glue is purchased in accordance with the costs of the flow rate indicated on the package.

Tip: In order to do not have problems with the materials while working, during the calculations of the number of rounding it is recommended to make up the increase, and each position must be purchased with a margin.

Mounting soft roofing technology - bitumen tile

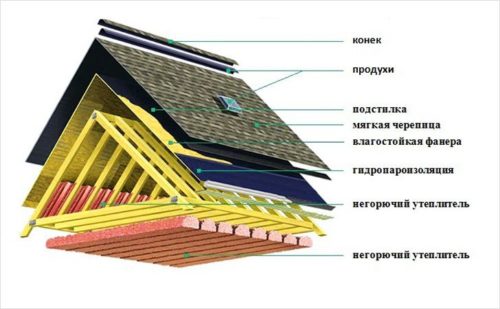

Laying bitumen tiles requires compliance with certain rules. First of all, it is necessary to prepare the basis of the roof.

- The manufacture of crates under the soft tile should be performed so that it can withstand the weight of the USB panels, the weight of the roofing material and the weight of the installers, as well as ice and snow. For this, the distance between horizontal bars (boards) of the crates is chosen not large - 150 mm (along the length of the element of the bitumen tiles). Section of timber - 15 × 100 mm.

- Brussia should not have damage in the form of dropped bitch, transverse cracks, signs of rot and "sinushnia". Material moisture - no more than 20%.

- When a solid crate of the board, the distance between them (about 5 mm) should ensure the expansion compensation due to changes in temperature and humidity.

- Natural ventilation must be provided.

- The USB plates are stacked so that their joints coincide with the installation site of the rafter.

- All wood must be treated with an antiseptic twice.

IMPORTANT: The design of the crate should provide for the presence of air ventilation passes in the field of cornisses and near the skate bar - for exhaust.

Tools for covering the roof of soft roof with their own hands

You can start working after the installer will have the necessary tool and fixtures. Next:

- bitumen mastic for gluing tiles;

- putty knife;

- sealant for filling the seams between tiles and vertical areas of ventilation channels and chimneys in places of their adjoining;

- roofing nails;

- hammer;

- construction stapler;

- construction knife;

- roulette;

- level;

- gloves.

Installations of installation of soft roof

After the maker will be ready, proceed to further work if weather conditions allow. The air temperature should be not lower than + 5 ° C, without precipitation.

- Over the solid crate of the USB slab, the lining material is laid, the base of which is a glass cholester impregnated with bitumen or polyester. From above, the lining canvas has a basalt sputter, it is protected from silicone film from below. Stacking it starts from below and continue to a skate with the adopted top canvase on the lower. The mount is carried out by a construction stapler, and at the bottom - nails.

- The edge of the eaves on top of the lining material is closed by cornice planets. They are needed to protect wood from moisture.

- Tile laying begins from the bottom row, along the cornese swell. Each next row closes the nails caps that the lower row is attached. In addition, the tiles are glued with cold bitumen mastic, which is applied with a spatula on the back side after its degreasing.

- The skate elements are stacked at the end of the coating mounting from left to right or vice versa. They must close the fastening elements of the tiles of the upper row.

- In the locations of the antennas, ventkanalov and chimneys, passing elements are mounted.

Tip: If a flexible tile from various parties, you need to mix all the items to avoid a sharp difference in color.

Installation of a soft roof - laying of rolled materials

The technology of installation of bitumen rolled materials depends on the presence of a self-adhesive layer. Ruberoid does not have adhesive base and therefore is placed in the following way (consider on the example of a flat roof with concrete overlapping).

- Preparation of the base of the roof: the screed is cleared, processed by primer. Cement-sandy mortar close chips and cracks.

- Rolled material is cut on the bands of the required length (determined by the length of the roof) and leave for the time for alignment, after which they are again unwound.

- Covered with a bid with bitumen mastic (primer). To work with mastic, they use quasha from the vet. At the same time, the roll is unwound, heated with its gas burner and pressing the rubberoid to the screed.

- Each next roll unwind over the edge of the previous one - at least 10 cm.

- The number of layers of roll material should be at least three.

- The outlets of the antennas, chimneys, ventilation channels are sealed with silicone cone-shaped seals.

- In places of drains to the walls, the ruberoid is stacked with 10-15 cm.

Similarly, laying the rubberoid on the surface of the scope roof, the design of which consists of rafters and a solid crate.

Installation of rolled material with adhesive base is performed without the use of bitumen mastic. The roll is unwinding with a metal kocher, having warmed it in the crucible place to the base.

IMPORTANT: Open fire work only in tarpaulin clothing, specialobuvi, safety glasses and gloves.

Main options for repair work soft roof

Soft bituminous roofing materials have weak resistance to mechanical effects. Branches of trees, strong wind, stretching antennas, cables and construction trash - all this can cause local damage. If they are critical - the roofing coating is subject to a complete replacement. The repair algorithm provides for performing work in a certain sequence.

- With the help of an ax, spatula and other tools, an old coating is dismantled, the base of the roof is carefully cleaned.

- Repair of the foundation is performed: cracks are eliminated, irregularities.

- The new coating is placed on the technology described above.

Local damage requires smaller time and materials to eliminate them. The method of repair in this case is as follows.

- Small holes and cracks are eliminated by the imposition of lathes. Initially, there are crushed cuts on the place of damage, wrapping the edges of the material aside. Pour bitumen mastic and put the latch carved in size. Disposable edges of the material back and pressed. On top of the bitumen mastic stick one more lathe.

- Swimming pierced, squeeze the air and pour the place of puncture with mastic. If "Dutes" are filled with water, they are repaired after the removal of moisture. To do this, after the cover of the coating uses a construction hairdryer.

- Separated joints restore: turn away the edge of the upper panels, they apply to it bituminous mastic and press the coating, carefully smoothing it.

In addition to the article on how the soft roof is stacked and repaired - vividly demonstrating the process.