In the construction of either the repair of the house at first glance it may seem that the main task of arranging the ceilings is their facial finish or design. In fact, this is not the case - as a rule, ceiling structures are a rather complex multicomponent system. When insulating the construction to preserve the optimal air exchange and further ensure the strength of the building, it is important to correctly perform steam barrier to the ceiling, ensuring the protection of the construction of the building from evaporation and exposure to moisture. Competent carrying out such work will ensure heat and comfort in the house.

Content

What does the ceiling vaporizion

At the final stage of construction, either in the process of repairing during the insulation of various surfaces of the house, the task of insulation of the room is often arises. At the same time, it is important to pay due attention to the issue, how to lay steam barrier on the ceiling. It is worth noting that the internal conditions are significantly affected by the microclimate in the room, i.e. The presence of moisture and steam. If there is no vapor insulation layer, then condensate can accumulate on the ceiling, which entails negative consequences in the form of moisture penetration into vapor-permeable insulation and negative impact on structural elements. The moisture deposited on the ceiling will lead to moisturizing the building. Using the installation of proper vapor barrier ceiling, you can avoid similar phenomena.

The vapor insulation material performs the following functions:

- protects the heater of the insulation from penetration and absorb moisture from the wet air rising, in which water vapors accumulate, and helps to maintain the heat-insulating properties of the roof;

- together with the insulation material, it provides an optimal microclimate indoors, contributing to preservation of stable humidity of air and reducing heat losses, regardless of temperature drops outside the construction;

- protects the elements of the building of the building from the appearance of fungi and mold, increases the service life of the used building materials;

- it can also act as an additional hydro and wind insulation of the room from weather influences.

With the help of thoughtful planning, how to sharpen vaporizoation on the ceiling, and carefully completed installation, together with the insulation, you can significantly increase the efficiency of sources of heat in the premises of the building. As a result of the work done, it is quite realistic to significantly reduce the cost of heating and electricity.

Types of materials for vapor barrier ceiling

Earlier, the choice of vapor barrier materials was small - rubberoid, polyethylene film and parchment were used to arrange ceiling structures. Currently, a significant amount of modern materials for the ceiling vapor barrier is presented with various permeability indicators. When choosing the most suitable material, it is necessary to consider for which surfaces it is planned to use, as well as the necessary bandwidth of such isolation. So that it serves for a long time, it will be necessary to take into account the material strength indicators.

For vapor barrier ceiling, you can use the following materials:

- polyethylene film - for hardening it is reinforced with a grid or cloth. Standard polyethylene film (non-perforated) is an impenetrable barrier that is tightly isolating moisture and warns the appearance of condensate on roofing structures and insulation. In addition, produced perforated polyethylene film with microcenes for better evaporation of condensate;

- pergamine - rolled material made of dense cardboard impregnated with bitumen. This material is characterized by low cost and low durability;

- polypropylene film - one of its sides is covered by cellulose fibers or viscose for optimal absorption of moisture. Thus, water drops are delayed with material and gradually evaporate. This material is characterized by a higher strength relative to polyethylene vaporizolation;

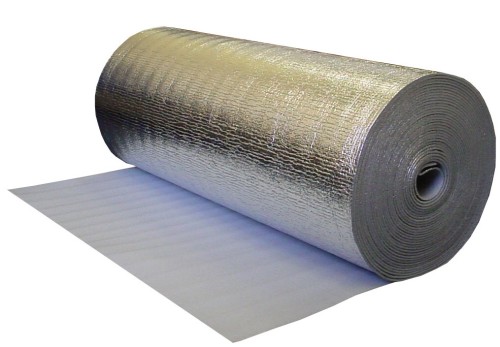

- aluminum foil performing the function of thermal radiation reflector, on a paper basis or on a layer of foamed polyethylene. These materials are distinguished by high vapor insulation properties and delay heat in heated rooms with an increased moisture mode. The most relevant use of such vaporizolation for the ceilings of the bath and sauna;

- diffusion membrane film - this microporphorized material, combining nonwoven polypropylene and polymer film, is one-layer and multilayer, single and double-sided. Modern membrane materials are created on the ceiling structures a barrier for a steam characterized by limited permeability and allow you to provide high-quality vapor and waterproofing. The diffuse film does not delay the surplus of moisture - getting into such a surface, they evaporate quickly enough. Extremely efficient and cost-effective vaporizolation can be ensured using double-sided membranes;

- lucky and masts with a membrane effect that do not pass by moisture outside and not interfering with an outflow of steam out of the room.

Polyethylene film is considered not too successful for mounting the ceiling vaporizolation, since with its use, the construction turns into a hermetically closed box that needs constant ventilation (otherwise moisture indoors can accumulate on the walls in the form of condensate and provoke the fungus or mold) . A similar effect provides pergamine - however, it is often used quite often due to low cost. The most effective vaporizolation allow membrane materials, reliably protect the ceiling from moisture exposure and not preventing excess steam outflows from the room outward.

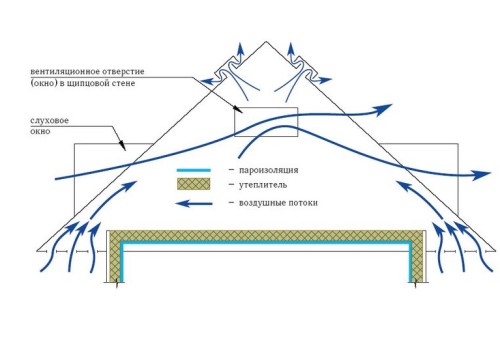

How to install vaporizolation

In most cases, a protective vaporizoation coating is mounted from the inside of the house when laying the insulation material. If the area in which the construction is located, is distinguished by harsh climatic conditions (in cases where the air temperature drops below -30 ° C), it is advisable to perform the installation of the ceiling vaporizolation on both sides - this molding method will ensure the most reliable protection against steam and save in House maximum heat. The outer insulation of the construction should be performed by placing the components of the structure as follows - vapor barrier, insulation and one more layer of vapor insulation material.

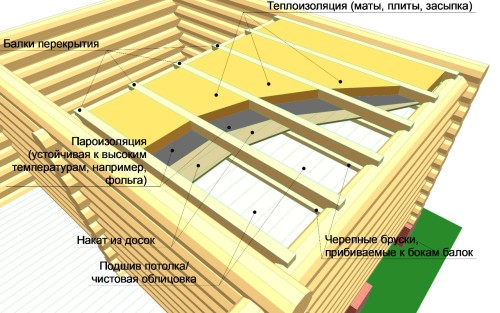

Tire ceilings can be equipped with both wooden houses and bricks - as an alternative to reinforced concrete plates. Under the action of moisture, wood is exposed to deformation, rotting and destruction, in addition, a significant heat leakage can occur through wooden structures. Thus, the installation of vapor insulation of wooden ceilings in heated houses is a necessity. This is especially true for premises located near places of the likely water leakage (under kitchen, bathroom, bathroom). In addition, mounted over the attic floor or an attic with a flat roof layer of vapor insulation material will also serve against blowing heat and to protect against wind.

Reinforced concrete ceiling floors also need high-quality vaporizoles, otherwise the condensate accumulating on them can cause fungus and mold appearance.

There are characteristic features of laying vaporizolation on the ceiling of the bath. It is necessary that such a building keeps the maximum heat, so it requires a "thermos effect". To do this, at the stage of construction, it is necessary to provide high-quality insulation from water vapor. As a rule, steam insulation in the form of an impenetrable energy-saving film or kraft paper with a metallized reflective layer (foil) is placed on the bath ceiling. Such material reliably protect the construction of the construction from the impact of high humidity and will serve in order to preserve heat indoors, as well as to protect against wind and penetration of cold air outside.

Installation of vapor insulation material: Useful Tips

Parosolation materials can be purchased in the form of sheets or rolls. The technology of their installation is simple, however, there are certain nuances that need to be taken into account when performing work. When planning, how to lay vapor insulation on the ceiling, it is worth considering the following features:

- this material creates protection for insulation from a wet steam, so it should be laid on the insulation from the inside of the warm room;

- many beginner masters find it difficult to determine which side to lay paosoolenia on the ceiling. When making installation it is necessary to take into account the following - the membrane material should be placed down towards the room by a rough surface, delaying moisture, while the smooth side will be seamless to the insulation. Materials with a foil side intended for reflection of thermal radiation should be located foil outwards;

- the film should be laid in such a way that it completely covered the entire surface of the ceiling, and at the same time lay slightly freely, without excessive tension, otherwise the material breaks may appear as a result of temperature deformations;

- to ensure reliable vapor barrier of the ceiling surface, it is required to lay a protective material with a holistic continuous layer without breaks and cracks. Separate paosity of vaporizolation should be attached to the flashes at least 10-15 cm - the basic staple brackets and on a thin rail, which tightly fit the material to the elements of the ceiling design. To ensure complete tightness, vapor insulation material in areas adjacent to the windows and doors, it is necessary to carefully smoke with a special scotch. In the angular places it is necessary to lay a solid cloth, which will qualitatively block the entire angle.

Sequence of steam barrier installation

Before laying a vapor barrier material, the surface of the ceiling should be prepared. To do this, it is necessary to clean it from dirt and dust. Steam barrier should be mounted after a complete burnt of the ceiling from moisture. If you plan to apply painting vapor insulation materials, it will also be necessary to close the surface irregularities.

Stages of work:

- at the installed layer of the insulation, it is necessary to sequentially to word in the vane vapor insulation film, fixing it in the joints of the joints with a bilateral adhesive tape. To eliminate the appearance of slots around the ceiling perimeter and properly seal the design, the material should be laid, capturing part of the walls;

- between the ceiling overlap beams, the vapor insulation material is necessary in a step of 30-40 mm to secure nails with wide hats or with a construction stapler;

- to fix the vapor barrier material on the draft coating, a crate of thin wooden or plastic rivers is used, a metal profile can also be used. In the case of the use of sheet vaporizolation, it will be necessary to build a frame from a special profile with grooves in which the sheets of the material are inserted. After that, the vapor insulation layer should be further consolidated on the self-tapping screw.

Ceiling pasting rubberoid for vaporizolation is performed using a preheated bitumen or bitumen-crooksol mastic applied uniformly and without skipping to the treated surface. In the angular zones and on the joints, the rubberoid should be placed with a naughty of several centimeters, and fasten with nails with wide hats. Ruberoid edges must be consolidated with special rails or exposed under the layer of insulation.

Liquid vapor insulation materials (heated bitumen or bitumen-crooksol mastic) are applied by a scraper or using an asphalt sprayer using a hose with a diameter of 28 mm. Lucky on the basis of a chlorinator or polyvinyl chloride is placed in two layers, while the second should be applied after complete grazing of the previous one.