To date, most private houses use natural gas for heating and cooking. Due to the high degree of automation of heating devices, blue fuel, many use it precisely. However, gas supply service is available in all regions, so wood ovens remain the main device for heating.

Content

- Types of metal solid fuel furnaces

- Principle of operation and design stove bourgeiske do it yourself

- Bourgeois stove bunching long burning with their own hands. Parameters of the furnace

- Installing the stove bourgeitors of long burning with their own hands

- Bourzuyka stove do it yourself: drawings, photos

- How to make a burgundy from the gas cylinder: video

The myth of the ineffectiveness of solid fuel furnaces has long been dispelled. Boilers and furnaces that work on stone corner and firewood, thanks to innovative solutions for their efficiency, if they were not equal to gas and electric boilers, at least approached it. Systems with thrust adjustment, automatic loading pellets, pyrolysis type of combustion of fuel are not involved in popularity. The reverse side of the hard-fuel furnace medal is their value that does not always allow them to establish them in non-residential premises, such as garage, bath, summer kitchen, etc. For such buildings where constant heating is not relevant, it makes no sense to install an expensive furnace or boiler.

The most optimal option can be the construction of a simple but efficient furnace with their own hands. If there are welding skills, this work will not seem too complex, and the result will exceed all expectations. About how to make burguly with your own hands - Next.

Types of metal solid fuel furnaces

- The most popular model of a solid fuel metal furnace is "bourgeitog". Its design and principle of operation are quite simple, which makes it easy to do at home. It is able to quickly heat the room, however, the firewood in it go beyond very quickly, which implies the need for constant loading of the furnace. In addition, the metal has a high thermal conductivity, because of which the burzhuyka also cool down, as he heated.

- Buleryan. This furnace is an improved version of the burzhuyki. The innovation of this model is to install the belt from the large diameter air pipes around the furnace housing. When heated, thanks to convection, cold air is absorbed into the pipe and it turns out hot. This effect allows the bulers to damn the premises of a large area.

- Furnaces of long burning. Recently, the homemade "bunch" has achieved great popularity. Such a gentle name oven received due to its creator. The principle of operation of this furnace is based on small air access to the furnace, so far the fuel is much slower. Production of the stove of the bourgeitogian cottages with their own hands is an easy task. This design due to long-term combustion is able to reduce the frequency of fuel loading.

Furnaces made of metal have a lot of advantages in comparison with their stone "relatives":

- One of the most important advantages is their mobility. Such a furnace can be transferred if necessary to another place, while without damaging it. It is impossible to do this with a stone stove.

- The next advantage of metal furnaces is their small weight, which allows when building a bath to abandon the construction of a massive foundation.

- Designs made of leaf or tubular rolled products are rather durable with proper manufacturing and care.

- Due to the high thermal conductivity of steel, the furnaces from this material pretty quickly heat the room.

- In such aggregates, any kind of fuel (firewood, coal, liquid fuel, etc. can be used.

- They have a simple design, due to which it can be done at home to a person familiar with the welding and processing of the metal.

True, it is worth noting that with the mass of its advantages, metal furnaces have some drawbacks:

- This installation is quickly heated, but also cooled with the same speed, so it is better to use solid wood solid so that there is no need to constantly throw firewood into the furnace.

- Heat from it is uneven, so for large rooms, it is better to install two furnaces.

Principle of operation and design stove bourgeiske do it yourself

The idea of \u200b\u200bmaking ovens or boilers of long burning is not new. Before making the first bubafoni, the Lithuanian company "Stropuva" created a boiler that had an unusual look at that time. The boiler was high enough and had a loading chamber in the middle of the case and several compartments.

The principle of operation of the boiler was in burning fuel not from the bottom-up, like most furnaces, but on the contrary. In this case, the air was supplied to the furnace in the dosage volume and heated to a temperature of + 400 ° C. A large amount of fuel is loaded into the furnace. With the help of flammable liquids, it is arson. Then the fuel lowers the pipe with nozzles for air supply. Fuel should slowly break. As the boiler exits the operating mode, pyrolysis gas, resulting from heated fuel, is surrounded in the chamber above the furnace, which increases the efficiency of the boiler. The combustion rate is adjusted by the air damper. In the bag of pyrolysis gases, a special regulator is installed, which switches the boiler to work with firewood or coal. In the boiler there is a water circuit that serves to heat the coolant.

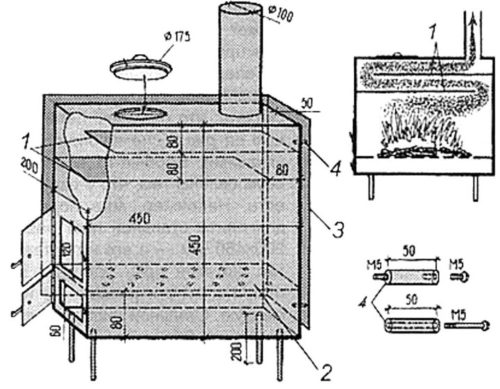

The developer of Bubafoni took the overall idea of \u200b\u200bthe boiler, a little simply simplified, finalized and made a simple oven, which consists of two cameras. The first fuel burns, pyrolysis gas burns in the second. Unlike the STROPUVA boiler, the bubonia does not have a water shirt, so only air can be heated. Another difference of Bubafoni from the factory boiler is the design of the air distributor. In the bub, it has a round view with branches. This allows you to maximize the sealing of the furnace and improve the burning in it.

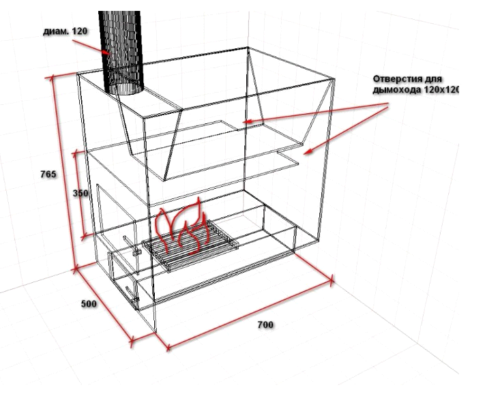

Bourgeois stove bunching long burning with their own hands. Parameters of the furnace

For efficient operation of the furnace, you must adhere to certain parameters.

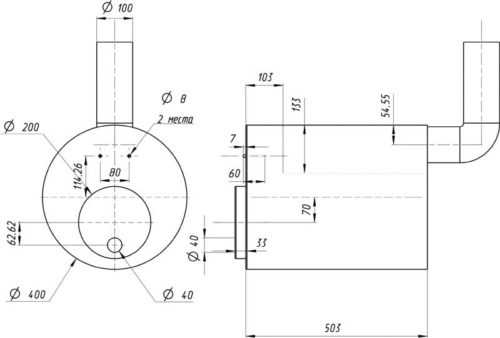

Thus, the size of the bubfoni hull should have the proportions from 1: 3 to 1: 5, where the first value is the diameter of the case, the second is height. This is very important, because with an increase in the diameter it will be almost impossible to achieve normal combustion of fuel at the walls of the furnace. Good burning will be only in the middle. This can lead to a seating of a pancake-dispenser, which can simply swam. With too small diameter, the incoming air furnace is not enough for normal combustion of fuel. It is just thrown out. The most optimal range of diameters of such furnaces ranges from 300 to 800 mm.

Metal thickness The furnace case depends on what purpose it will be used. If a water jacket for the heating circuit is dressed on it, then the thickness of the housing walls should be at least 4-6 mm. If the furnace is used for air heating, the thickness of the metal metal can be less. Recently, metal barrels of 200 liters have become a popular material for the manufacture of bubphones due to their cheapness. However, too thin metal with intensive use can simply turn around. For a small oven, the thickness of the metal of 2.5 mm will be enough.

The following main parameter of the bubphony design stove burzhuyki is the size of the disk. The gap between the disk and walls should be no more than 5% of the inner diameter of the furnace. A special role is played by the thickness of the disk blank. According to the experience of the development and operation of these stoves, it can be said that the thickness of the workpiece is inversely proportional to the diameter of the furnace. If you do too heavy pancake, it can simply zagasya all the flames by pressing the fuel with its weight. In the opposite case, not only the upper, but also the bottom layer of fuel can be omitted in the absence of a normal press. In this case, the effect of the reverse thrust may occur when the air will be absorbed through the chimney, and carbon monoxide goes through the air duct. For an oven with a diameter of a housing is 800 mm, the thickness of the pancake should be from 2.5 mm to 4 mm.

In the manufacture of bubfoni, it is important to calculate the height of the ribs of the air ducts. This parameter is proportional to the furnace diameter. So for the housing with a diameter of 800 mm, the height of the ribs should be at least 80 mm. In this case, the fuel will get a normal oxygen volume to maintain the optimal combustion process. To improve the work of the furnace blades on the disk can be welded in the form of curved blades.

Next, one of the most important parameters of a solid fuel furnace is calculated - the diameter of the chimney nozzle. The cross-sectional area of \u200b\u200bthe chimney is calculated by multiplying the energy estimates of the furnace to the coefficient of 1.75 (derived by experimental way). At the same time, the energy estimation is calculated as a product of the mass of fuel and its specific heat transfer. In this case, the mass is calculated depending on the volume of the furnace and the specific coefficient of fuel bookmark.

Air supply pipe, which is optional to damn, must have a diameter of at least 76 mm. Otherwise, the oven simply does not have enough air. A typical mistake of many masters who are trying to boil with their own hands, is that they do not apply a protective collar. At the same time, the slot between the pipe and the hole in the furnace arch contributes to the suction of excess air into the afterburning chamber of pyrolysis gases, which reduces the efficiency of the furnace.

Additional calculated parameters that need to be considered in the production of bubfoni:

- Height of the lower edge of the loading door from the lower end of the furnace.

- Distance from chimney to the furnace arch.

- The height of the door pissed.

- Air supply pipe height.

All welding works on the manufacture of bubfoni must be carried out carefully, not allowing the appearance of holes through which air can leak. The lid pondered and the loading hatch should fit tightly to the body so that the air does not succeed through them. In this case, the combustion will occur more intensively, which will reduce the KPD of the furnace.

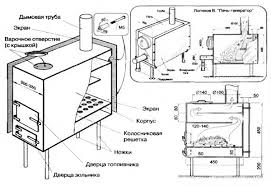

Installing the stove bourgeitors of long burning with their own hands

After the furnace is made, it must be properly installed. It is necessary to take into account the fact that the burning of fuel in it takes place to the nose itself, so the lower part of the furnace will be exposed to high temperatures. Under these conditions, regardless of whether the bubfoni legs will be in or not, it must be installed on the foundation from refractory materials. Simple concrete from high temperature will simply begin to crack.

The height of the chimney tube should be at least 4200 mm. Otherwise, the furnace does not have enough thrust for fuel survivors in the second chamber, and she just suffocates.

The length of the horizontal flue of the chimney to the insertion into the vertical often should not exceed 400 mm. However, it is not necessary to make it too short, can break the thermal balance of the furnace.

The vertical pipe of the chimney of the stove bourgearies should have a condensate collection with their own hands. Usually the end of the pipe is brewed below 300 mm from the scene of the horizontal nozzle and the ball valve is screwed. In the process of combustion of even dry wood, a certain amount of steam is distinguished, which will be dragged along the walls of the chimney into the condensate collection. After a certain time, condensate merges through the crane.