The correct adjoining of the roof to the chimney is one of the most important conditions when the roof is arranged. The reliability of the design and operational period of the roof depend on the quality of the work.

Content

Features of assembly work

Sealing issues of contact elements are solved in the design of roofing design. All factors are taken into account:

- roofing material;

- form and location of the chimney;

- pipe manufacturing material.

The simplest occupation will be the waterproofing of the roof of the chimney located in the highest point of the scope design. In this case, the snow will not accumulate near the pipe, and the moisture will not be able to penetrate into the inner part of the roof.

There will be no problems with waterproofing the adjuncing of roofing material to the pipe, which is below the skate. If the chimney will touch the bottom of the pitched roof, the pipe is additionally equipped with slit elements with slips.

It is not recommended to mount the chimney, which will intersect with the endo. There is a high probability of depressing roofing.

Based on the foregoing, it should be noted the possibility of the pipeline in any part of the roof. The only requirement is presented to the height of the chimney above the roof, which may vary depending on the distance to the skate:

- up to 1.5 m - the minimum height over the skate is 0.5 m;

- 1.5-3 m - the pipe can be at the level of the skate (or slightly higher);

- over 3 m - the upper part of the chimney is placed on the line, which is 10-12º exceeds the level of the skate.

The pipe itself is also desirable to close with a special umbrella. It will protect the chimney against precipitation and condensate, which in frosty weather can cause to be laid. That will lead to a deterioration of thrust in the heating system and reduce the life of the chimney and the roofing material.

Chimney and roofing pie

In order for the roof pass to the chimney differed with the maximum reliability, it is necessary to observe the only requirement - the lamp under roofing material must have increased rigidity with a uniform load distribution emanating from the elements of the roof and natural factors (wind, snow).

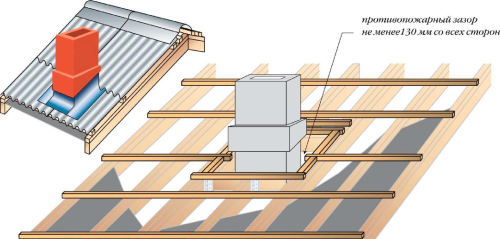

When installing a chimney, which has a rectangular shape, in most cases on a certain section of the roof, it will take a disassembly of the frame. Usually the removal of the part of the rafter legs.

Naturally, the best option will be the creation of a separate zone in the node of the flue of the chimney through the roof. The pipe should be separated from the roof using rafters (in the lateral part of the chimney) and transverse beams between the rafters (at the top and bottom points of the pipe).

In order not to reduce the carrying characteristics of the structure, the chimney is equipped with an additional crate with steam barrier and waterproofing on it. The waterproofing material is fixed with a frame, and a vapor barrier film - elements of the crates intended for fastening the finishing material.

To create the most efficient protection of the design from the negative impact of a wet environment, waterproofing and vapor insulation materials are stacked throughout the roof without breaks. The stacked materials are protected from moisture using a special adhesive tape, which connects materials with a pipe and wooden elements without jams.

To achieve optimal fireproof, the distance between the roof elements, which are made of flammable material, and the chimney itself should exceed 13 cm. The passage of the chimney through the roof is filled with non-flammable material (for example, stone cotton).

Right docking chimney and roofs

Tile to chimney pipe

For the arrangement of the adjustment of ceramic (or sand-cement) tiles to the chimney pipe should be used:

- special aprons;

- elastic ribbons, during the production of which was used aluminum.

The sealing process itself consists of the following steps:

- adhesive side of the tape are stuck on the joint;

- one half of the tape should be located on the roofing material, the second - on the pipe;

- the upper part of the elastic ribbon is fixed with a metal bar that is fastened with a dowel;

- wire of screwing up dowels and plank joints close up with sealant.

The sealing technology of the roofing unit made of flexible tiles is similar to the above. The only difference lies in the fact that the elastic tape is replaced with tiles, in advance in the chimney.

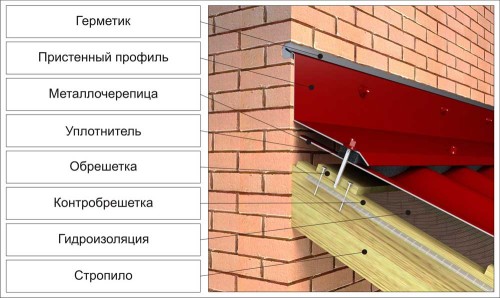

Metal tile for chimney

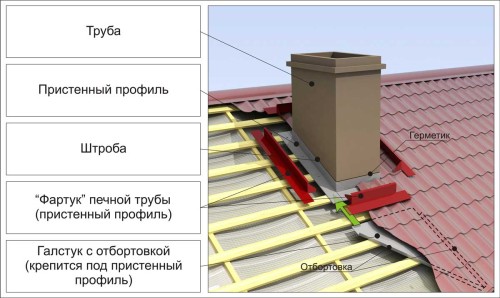

When climbing the smoke of the chimney through the roof made of metal tile, it is necessary to use the apron with the upper and lower straps:

- the bottom plank is applied to the chimney and the location of its upper edge is noted;

- according to the markup made, shtrtob (its depth is 15-20 mm);

- the surface of the chimney is cleared of dust;

- the installation of the planks is made (the backstage is 15-20 cm);

- the insertion of the top of the planks in the stroke is carried out;

- everything is treated with silicone sealant;

- a metal sheet is inserted below the apron, which is designed for water flow;

- hammer and passage in the sheet, the side is made;

- the masonry metal tiles around the pipe occurs;

- installation of the upper slats is carried out directly to the wall of the chimney (it is not necessary to stick it);

- the joints are sealed.

To obtain the most reliable adjustment before creating an internal apron, it is necessary to lay a heat-resistant waterproofing material, the top edge of which is fixed using a tape.

Round pipe adjoining

For sealing roof adjoins to a pipe that has a round shape, special products are used. They are plates that consist of two main elements:

- flat sheet of steel;

- apron Cap.

Sealing adjoining implies the following actions:

- circumcipation of the upper part of the apron-cap (the pipe should enter it as tight as possible);

- fixation of the plate on the same plane with roofing (applied screws with rubber gasket);

- pressing the top edge of the cap to the pipe (used steel clamp, equipped with an elastic gasket).

It should be noted that the plates are produced that are intended to close the roof adjoins with the most occurring corner of the roof slope. If the plate is not suitable, then around the pipe to build apron will have to be independently.

The easiest way is to envelop the junctions of an aluminum or lead ribbon. To ensure high quality installation work, the surface on which the tape is pasted should be dry and clean.

You can use the finished oval product made from lead. Why exactly lead? This is explained by the fact that this metal has elevated resistance to temperature differences, corrosion processes and exposure to ultraviolet rays.

Video about creating a reliable roof adjustment to chimney: