The use of profiled pipes for the construction and manufacture of metal products has recently become almost ubiquitous. Pipes of square section perfectly proven themselves as light, but very reliable material. It is often used to build ordinary, but durable structures, such as balcony frames, canopies, arbors, greenhouses.

Content

- Principle of operation and device of the pipe bending machine

- Materials for the manufacture of pipe-loading for the profile pipe with their own hands

- Profile pipe bender do it yourself. Safety requirements when working with metal

- Pipe bender for pipes with your own hands with a central adjustment roller

- Making a pipe bender with their own hands with a side adjustment roller

- Pipe bender do it yourself: drawings, photos

- Pipe bender do it yourself: video

Principle of operation and device of the pipe bending machine

Greenhouses, greenhouses, greenhouses, as a rule, have an arched shape, so the pipe will need to bent. You can do this in two ways:

- Manually, preheated pipe. This option is suitable only for small amounts of work. It has a number of significant drawbacks. First, when heated, the properties of the metal change, which can adversely affect the strength of the entire structure. Secondly, in the manufacture of bending manually, it will be difficult to achieve accuracy of each part. Yes, and make the perfect radius manually impossible.

- With the help of a pipe bending machine. This is the most optimal option. The accuracy of the manufacture of parts with a given arc radius, high performance in comparison with manual work - make this method most preferable.

If the pipe bending machine will be used on an industrial scale for doing business, it makes sense to acquire the factory model. If it is needed for a single job, either will need from time to time, it makes no sense to spend considerable funds for the purchase. You can rent it or make it yourself. About how to make pipe bender with your own hands for the profile pipe - further in the article.

Before starting the process of manufacturing a pipe-bender with your own hands, it is necessary to clearly understand what it consists of and how it works.

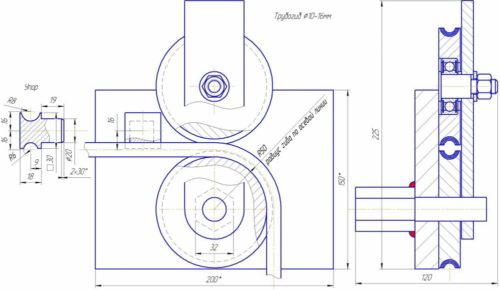

The principle of the operation of the pipe-bending is quite simple. Smooth pipe rolled between moving rolls, one of which can change its position along the vertical axis. Due to the pressure of the central roll, the billet is bending at a certain angle. The applied pressure is not in one, but at several points, is the key to the uniform bending of the pipe, without breaking its surfaces.

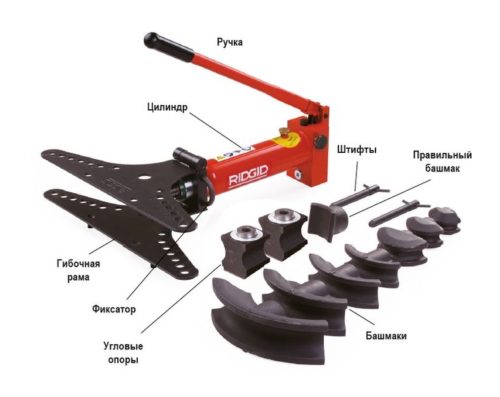

The design of the pipe bending is also pretty simple. The main nodes of the pipe bending machine are as follows:

- Stanna. It is a welded metal structure on which all parts of the machine are installed, including the guide roller, a mechanism for changing the pipe rolling angle, drive mechanism.

- Set of rollers. As a rule, simple pipe bending has 3 rollers, two of which are rigidly fixed on the bed, and the third has a free course. Thanks to this design, you can change the angle of rolling, and, accordingly, the radius of the part. The machine must have a special device for fixing the position of the pipe during rolling, which will allow rolling the design of different sections without displacement.

- Drive unit. To move the workpiece on the machine, one of the shafts, as a rule, is the central upper shaft, should give her movement, simply rotate. For this, the drive is connected to it. It can be an electric, hydraulic or manual drive. In home-made pipe bending, the last is usually used.

The design of the frame of pipe bearing machines is two types:

- Closed.

- Open.

Products made at home are usually completed with additional elements that simplify the operation of the unit.

Materials for the manufacture of pipe-loading for the profile pipe with their own hands

Despite some difficulty design, the manufacture of a pipe bending machine does not require special material costs. Most details can be bought on disassembly or items of receiving scrap metal. At the same time, in comparison with not too strong factory handlets, it is really powerful, even if not so beautiful, the machine that will serve for many years. In order to determine the need for materials, it is better to make the drawings of the profile pipe bending with their own hands.

For the manufacture of the bed will take:

- Schweller with a width of at least 140 mm.

- Several channels 5p with a width of a 50 mm shelf for roller supports.

- In some cases, it is possible to use steel round rolling of solid steel grades.

- For stops, three pairs of bearings are used on the bed. Their inner diameter is selected under the diameter of the shafts.

- If the upper roller is adjustable, then the clamp screw and the nut of the corresponding diameter will be needed for the mechanism of its raising and lowering. In this case, only lower rollers can be driven. An ordinary drive from an old bicycle is welded on their shafts, which leads them to move.

You can make pipe bender with a movable lower extreme roller. Then the bed is not done whole, but the national team, with a movable back. The ordinary hydraulic jack can be stopped for it. In the case of an adjustable bottom roller, manual drive is welded to the top, which will be driven.

As a manual drive, a handle with a large shoulder is necessary. It facilitates the effort that needs to be applied to bending a profile pipe with a large cross-section area.

The last design is more convenient and easy to manufacture.

From the tool for this paper, you will need:

- Bulgarian with a circle diameter of at least 230 mm for cutting thick-walled metal and stripping welding seams.

- Welding machine with a set of electrodes.

- Roulette, ruler, male drawer, chalk.

Profile pipe bender do it yourself. Safety requirements when working with metal

When cutting, welding and stripping metal, it is necessary to strictly follow the safety rules:

- When working with the welding machine, it is necessary to have a fire extinguisher. It is advisable to spend these works together.

- It is necessary to work only in special clothing with the use of personal protective equipment:

- welding shield;

- mask or glasses for working with a grinder;

- mittens.

Pipe bender for pipes with your own hands with a central adjustment roller

In the presence of necessary materials and welding skills, the pipe bending machine can be collected in 1 day.

The order of work is as follows:

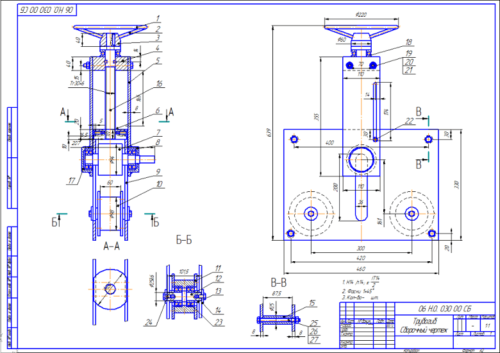

- To begin with, it is necessary to make a bed and focusing for a roller clamp screw. The bed in this case will be solid. Its length is chosen at its discretion. In the center of the bed, the focus for the roller clamp screw is constructed. Its height should not be greater than the free turn of the screw. The P-shaped support is welded from Schweller 5P pieces, processed and welded to the bed. The main metal structures of the machine is ready.

- Now in the center of the crossbar is drilled by a hole, a diameter of equal diameter of the screw. Next, a screw carving nut is welded to this hole. The ideal solution in the manufacture of the clamping mechanism will be the use of the screw of the old clamp. After cooling the nut, it is lubricated with lubricant and drive a screw several times to go free.

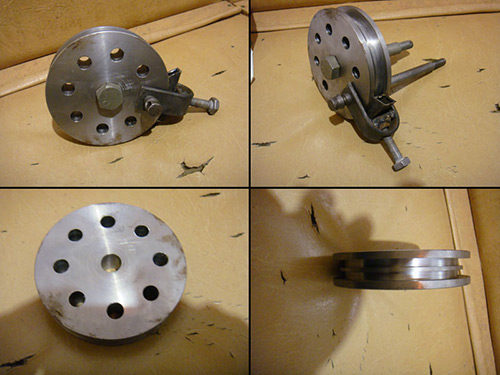

- Next is made by pressure roller. The basis for him will be a piece of channel 5p, the length of which is equal to the distance between the support racks. On the outer side of the shelf, two casings of rolling bearings with an inner planting diameter of 30 mm are welded. The shaft is inserted into the bearings. If you sharpen his problem, you can take a piece of thick-walled pipe of the corresponding diameter or round rolled steel. The ideal shaft landing accuracy is not needed here. So that it does not fall out of the bearing, it is grabbed to the inside of the clip.

- Next, the chaserler welds to the end of the screw. Now, when you rotate the last clockwise, the clamping roller will be descended, when rotating counterclockwise, ride, thereby adjusting the radius of the pipe rounding.

- Now you can install side rollers. For their foundation, two pieces of channel 5p are welded at the ends of the bed, the length of which is 140 mm. Two pairs of bearings are welded at their ends, the same size that was used for the pressure roller device. The identical shafts are installed between them, which also stick to the internal bearing rockets.

- Now the tube rolling mechanism is ready. You must install its drive. The idea is to synchronize the movement of the side rollers to move the workpiece at one speed. To do this, a handle welded one of the rollers on one side. You can use part of the cycling pedal. On the other side of the same shaft welded a drive asterisk (also cycling), which will be connected to the same on the opposite shaft.

- A bicycle chain is used to connect asterisks, the length of which must be adjusted for normal stretch. Now the shafts will rotate at the same speed, due to which the billet will be more evenly rolled.

Making a pipe bender with their own hands with a side adjustment roller

Fundamentally, the machine diagram does not differ from the above. There is also a pair of lower rollers and one top. The only difference is that the adjustment roller is not central, but side. For this, the bed is not done whole, but the team. On one part (motionless), the upper central and lower side roller is installed. At the same time, the central is fixed at a height of equal to the maximum height of the processed workpiece.

On the other hand, the moving part of the bed with rolleropor is attached to the steel loops. A jack is installed under it, which, if necessary, raise it, thereby changing the pipe radius. In this design, the movement of the workpiece provides a central roller, whose shaft is attached to the handle. The welding process and the sizes of the window of the pipe bending machine in two versions are identical, which one is better - it is necessary to solve depending on the purpose and availability of the material.