If you built a bath in your country, it is sooner or later you will have to shut it with her stove. An excellent option will be a metal furnace for a Russian bath, made with their own hands. If you do everything yourself, you can save well, while your design will not be worse than the shopping option. In this article, we will try to fully disclose the question associated with the propelled assembly and installation of a metal cooker.

Content

General characteristics of metal furnaces for a bath

So that in the bath was nice to steam, it is necessary to install the corresponding furnace in it. Take advantage of this issue with full responsibility, then you can choose the appropriate option. There are several options for bathing furnaces, it can be a cast iron or metal and a classic bath on firewood. You can also meet gas stoves that are gaining increasing popularity.

Advantages of metal furnaces for a bath

Baths equipped with metal furnaces are quite widespread. The popularity of such furnaces is due to a fairly easy way to manufacture and editing.

The main advantages of metal bath furnaces include the following:

- heating rate. With the correct selection of parameters, metal furnaces are able to warm the room in 1.5-2 hours. If compared with alternative embodiments, such indicators are the highest;

- cheap manufacture. Compared to the rest of the options, the metal furnace, manufactured independently, will cost much less. At the same time, it will not give up according to the characteristics possible analogues;

- long service life. If you selected the correct material, in accordance with the parameters of the heated room, then such a design may be served for a long time (up to 25 years);

- reliability. You may not worry about the problems associated with the smoke of the room of the bath. The main thing is to initially make the right assembly, as well as adhere to all instructions during operation;

- creating designer forms. A little imagination and you can create an exclusive furnace according to our own drawings, the main thing is that its internal device is not impaired.

As we can see, metal furnaces have quite a lot of advantages, thanks to which they can be attributed to the popular way to equip the Russian baths. To the furnace, with each heating, it worked accordingly, it is necessary to make installation in accordance with the safety regulations. Otherwise, the oven will not produce the necessary heat, and maintain a constant temperature.

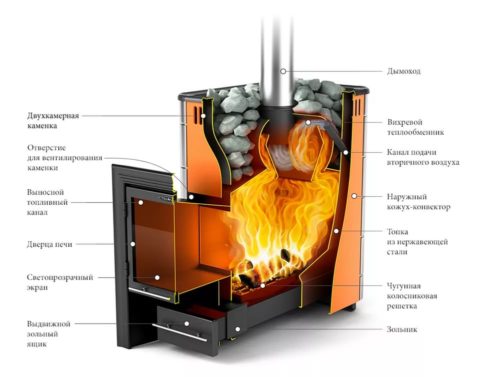

Bath Metal Furnace Device

Before considering the main stages of the manufacture of a metal furnace, it is necessary to figure it out in its device. All stoves made of metal have about the same stuffing consisting of several parts.

Metal bath furnace has the following components:

- fuel chamber (fuel), which includes: pissed, ash tank and door. The chamber serves fuel (firewood, coal, briquettes), where under the influence of the combustion process was carried out. With the help of the ash, the remains of burnt fuel (ash, ash) are collected. For this, it contains a special grid that must be cleaned periodically. The fuel can be placed as inside and outside;

- capacity with stones (bunker). Located in the top of the fuel chamber, and is a grille, with stones placed on it. The bunker can be executed both in the open and in the closed version. If you need to replace stones or simply add a steam, then the container is equipped with an additional door. Note that the bunker in this case should be closed;

- water tank (capacity). It is usually located in the upper part of the furnace. Capacity ishing the chimney, which allows it to heat up in the process of the harvest. The tank is equipped with a special drain crane, which allows access to hot water;

- chimney. Usually made of metal pipe, and allows the gases that arose in the process of combustion of fuel, outward the premises.

The functioning of the metal furnace in the bath is impossible without using all of the above elements. Interacting with each other, they allow the ovens to produce heat as much as possible, gives us anything with any comparable pleasure.

Metal bath furnace

As yours has already stipulated, the fuel is equipped with a hopper with heated stones that help maintain the necessary heat for a long time. Without stones, the walls are not capable of holding the desired temperature for a long time. In addition, in the heating process, the metal highlights strong infrared radiation.

To avoid overheating of the furnace, you need to equip it with a furnace using one of the following methods at the same time:

- Futher on firebox. This method provides for the facing of the furnace furnace with the help of heat-resistant brick, laying it on the edge (thickness 60 mm). In this case, a significant part of the useful heat goes into the brick that protects the room from IR radiation. Heated stone longer keeps heat in itself, however, the lining has a negative property. Since smoke having a very high temperature takes part in this process, this method is sufficiently flawed. To somehow cool the smoke, the furnace is equipped with water tank. There is also a more complex option when the furnace is equipped with a special heating shield.

- Sarcophag - laid out around the furnace screen of bricks. In this case, the metal walls are equipped with windows or doors that allow you to adjust the temperature in the bath. However, such a method also has a drawback - with constant heating, the metal is badly cold, and roars. For this option, it is better to acquire thick metal.

Professional Council: Most often, the back and top of the furnace goes around. When assembling a metal furnace, for these parts, use the sheets of the greatest thickness or heat-resistant steel. They will determine the service life of your design.

In any case, choosing one or another method of furnace furnace, note that the metal furnace should be tightly welded. Seams are most susceptible to root. The thicker the angular connection will be welded, the longer you will serve a stove.

Homemade metal furnace with their own hands

If you have gathered yourself to make a metal furnace for a bath, then you will need some knowledge, without which the installation will be impossible. Failure to comply with the rules of installation over time can lead to undesirable consequences, for example, insufficient prevocation of the premises or the root of the metal. Below, we give an example of the assembly and installation of a homemade metal furnace standard size for small rooms.

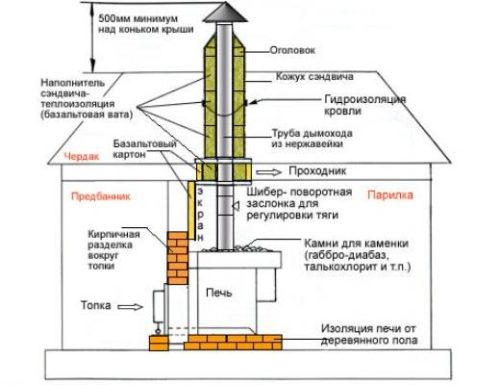

Metal furnace installation rules

To spend all work correctly, follow the following recommendations:

- as a base for a furnace arrange the foundation. For this, it is perfectly suitable for a brick, laid on a specialized mixture in several rows. The base area should be clearly in the level to the horizon, while matching the sizes of the future furnace. One of the common sizes of the base is 700x700 mm and 200 mm thick;

- if the furnace is mounted in a wooden room, and is lined with brick, it must be installed at least 200 mm from the wall;

- if the oven is purely metallic outside, then it should be from wooden walls at least 1000 mm;

- if the premises parameters do not allow to follow these rules, the special layer of thermal insulation or reflector can be mounted on the walls;

- to separate the bath from the pre-banner, install the brick partition.

As you can see, all of the above rules are simple enough, and aimed at improving the fire safety of the room. Follow our recommendations, then the bath will serve you not one year.

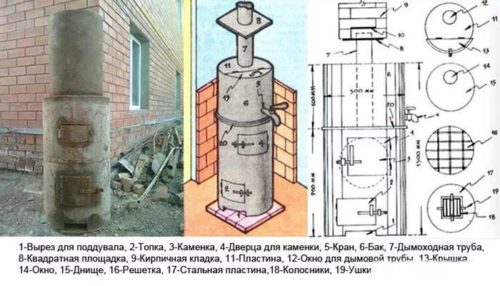

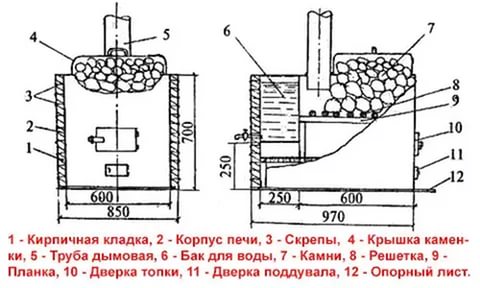

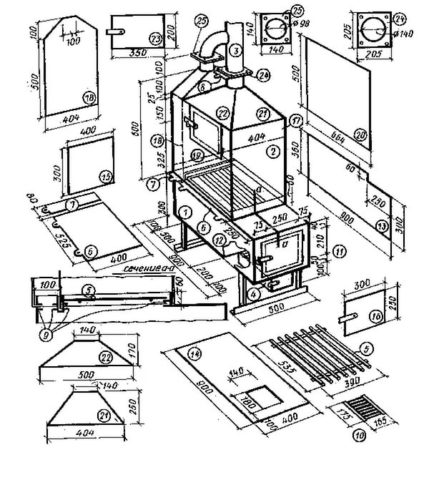

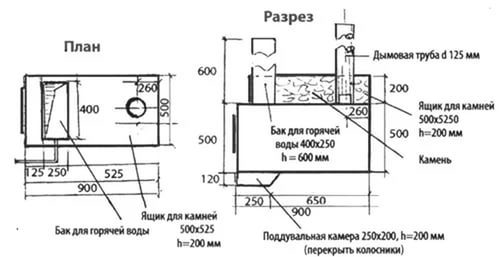

Drawings of a metal furnace for a bath

As in any other case, the creation of a bantal furnace requires preliminary design. Before proceeding with work, you need to create a design project, with all the desired sizes in the drawings.

Below, we give several options for drawings with which you can build a high-quality furnace:

Tools and materials

Since the installation of a metal furnace provides not only the masonry, but also welding work, then it is necessary to thoroughly prepare. Next, we give a list of all necessary to create a furnace with a diameter of 700 mm and a height of 1600 mm.

For this, we advise you to purchase the following tools and materials:

- welding machine, Bulgarian, drill;

- level, roulette, carbon, marker;

- saw on a stone, a file, shoulder, spatula, trowel;

- discs for cutting and stripping metal, disk on stone, nozzle-mixer;

- electrodes (in accordance with the thickness of the selected metal);

- metal sheet 10x1000x2200 mm;

- pipe 10x700x1600 mm;

- pipe for chimney 10x100x1000 mm;

- steel rod (rolling) d \u003d 10 mm;

- cast iron grille, 3 pins, 8 loops;

- ball valve for water tank;

- reflector or thermal insulation, specialized brick adhesive, brick;

- protective mask, glasses, gloves, special equipment.

Such a set of tools and materials will significantly simplify the process of manufacturing and installing a metal bath. In case you use an old metal barrel Go any other material that has already been used, keep in mind that the service life of your product will be short. Be sure to purchase only thick metal. We also recommend to produce a furnace in a square or rectangular design, which will be much easier and faster than the design of intricate forms.

Step-by-step instruction for assembling a metal furnace for a bath

Immediately, I would like to note that the assembly of such a kind involves the use of some skills when working with the welding machine. If you have never come across this, it is better to start strain on metal trimming.

To independently make and install a metal furnace for a bath, stick to the following sequence of actions:

- Mock first pedestal (base). In a pre-marked place 700x700 mm, put the brick on special glue into three layers.

- Make sure the solution is frozen, and the brick is laid in a horizontal level. Use the construction level.

- With the help of a grinder, cut the pipe into two parts: 700 mm and 900 mm.

- From the bottom of the long section back down to 80 mm, then with a marker draw a rectangle 200x50 mm.

- Up the tube, parallel to the previous rectangle at a distance of 40 mm from one another, draw the same.

- Cut out of the pipe both rectangles. Note that after cutting, they need us more as doors, so follow all neatly and carefully. Thus, the bottom hole will play the role of the ash, and the top - for fuel loading.

- The pipe is welded hinges, and door - latch. You can then connect the door with the pipe.

- The metal sheet draw a circle 700 mm in diameter. Cut it with a grinder.

- In the middle of the cut circle cut hole which corresponds to the dimensions previously purchased lattice.

- The circle with a hole is welded to the pipe. Make sure all joints are well cooked.

- More above through a pipe, cut another hole. It will be used for loading stones. Do not forget that from the cut material is also necessary to make the door.

- Make a grate for stones. The material used wire rod, which must be welded to the step in accordance with the size of the stone (so they do not fall into the furnace).

- Cut another metal circle 700 mm in diameter. He will play the role of a cover for a container with stones. In the middle of the circle is cut a hole diameter of 100 mm. We need it for the chimney.

- The resulting structure is welded to the top of the pipe.

- Now cut the pipe 700 mm in length 100 mm. Is welded to the structure from above, that we turned the water tank.

- In doing tank hole of corresponding diameter, and then welds or ball valve is screwed into it.

- Again cut a circle of 700 mm diameter. Circle need cut it into 2 unequal parts.

- In most of the cut opening 100 mm below the chimney, and to a lesser welds loop.

- Most of welds completely to the top, and a lower hinge, so you can later add water.

As you can see, their own cook and install a metal stove for a bath at home is quite realistic. Needs a bit of patience and skill, then the process does not seem like that difficult. Always follow the safety rules. And remember the main thing - the thicker the metal, the longer the life of the furnace. Pay particular attention to filling welds.

We hope our article helped you deal with the issue of bathing the bath in cottages using a metal furnace. Do everything consistently and carefully, then excellent feelings from the steam room in your own bath you are provided.