Ceramic tiles are widely used as a decorative finishing finish, and it is possible to meet it both indoors and on the facades of buildings. This material has gained great popularity due to its wear resistance, durability, a huge range of forms and colors, as well as an affordable price. In this article we will talk about the lining of the walls with ceramic tiles.

Content

Types of ceramic tile

The material of this kind is made of natural components, the main of which are clay and sand. The components are mixed, pressed and burned from one to several times at high temperatures. By adding dyes, applying glaze, drawings and reliefs to the tile of glaze, drawings and reliefs, it is given a final decorative look. Depending on how the coating has a tile, it is separated into two types:

- The unpacked tile is the simplest and unattended material, which, besides, is relatively cheap. Elements of such cladding are often painted in one shade and have a matte surface that absorbs moisture. Due to poor hydrophobicity, the ceramic tile of this type in the facing of the outer walls does not apply. Against the finishes of the facades, this material indicates this characteristic as high fragility.

- The glazed tile is more expensive, but also a more wear-resistant type of decorative finish. A thin layer of durable waterproof glaze is applied to the front of such a material, which gives the tile of beautiful shine and tint, and also ensures the presence of a pattern or ornament. The glossy surface makes the tile of durable, solid, moisture resistant and durable.

Ceramic tiles are made by different technologies, for example, it can be subjected to single or twofold firing. In the first case, the process of creating a material is to connect the components of raw materials, their pressing, the coating of icing and baking in the furnace. The final products will turn out low, dense and strong enough. But the dimensions of such tiles in different batches may differ slightly from each other. When using tiles in outdoor work, this deficiency is not too striking, but the tile itself has a democratic price.

The technology of double firing differs from the first method by the fact that decorative glaze is applied to ready-made burned products, after which they are re-baked in the furnace. As a result, the tile turns out to be smoother, smooth, very attractive and brilliant, not containing on the surface of defects in the form of cracks and shells. It will be more expensive to cost this facing material, but for interior decoration it is optimal.

Classify the tile can also be sizes. For example, the floor tile is produced in such dimensions: 30x30 cm, 40x40 cm, 45x45 cm. Flooring most often has a one-time firing, as it should not necessarily be perfectly smooth, but its strength and low porosity are very important.

Wall tile is produced in a variety of sizes. The mosaic tile is very small, with the sides of 2 cm. There is a tile with dimensions of 5x5, 10x10 cm, but the dimensions of 20x20, 20x25, 15x25 cm are considered standard.

Sometimes it is possible to find rather large elements with 60 cm sides, as well as 60x120-dimensional tiles. For wall cladding, special equipment will have to use such details.

Pros and cons of ceramic tiles

To understand whether to separate the walls with tiles, you need to consider the advantages of this coating:

- The technology of creating ceramic tiles allows you to make the material extremely solid and dense, which greatly affects the wear resistance of the coating and the period of its operation.

- Materials that are part of ceramics are absolutely eco-friendly, do not harm the environment and human health.

- The coating of this type is not lit and is considered to be fireproof.

- The tile is not extended by almost no chemical compositions and is stable before abrasive cleaners. This means that for its washing, any means can be applied. The smooth water repellent surface of the tile makes care for it even easier.

- Ceramics does not conduct electricity, which is an important characteristic of the material that is used in the interior decoration.

- The material is available on sale in a wide variety of forms, sizes, colors and textures. From such an assortment you can choose cladding for any design and style of the room. The price of wall cladding with ceramic tiles will also vary widely, and therefore, almost anyone can find material in its budget.

- The dense and solid surface of ceramics makes it stable before physical influences and mechanical damage. Split the material on the part only with a sharp effect, for example, if you drop something heavy on it.

- Such a coating can be decorate any premises, including those where high humidity is present.

- With the help of the tile, it is easy to disguise insignificant flaws on the surface of the walls.

- Ceramic tile is universal and suitable for both internal and exterior finishes.

I will not lose sight of the minuses of such a coating, which can be attributed to:

- High thermal conductivity. Floors and walls, lined with ceramic tiles, cold-tight, and if it is not a significant disadvantage for the walls, the floor in the house, laid out with a cafeter, will have to be stuck with carpets or tracks.

- The fragility of the material is another of the minuses. It is necessary to transport ceramic tiles to be careful, so as not to break it. But after laying on the wall, the coating will become very durable and it will be quite difficult to damage it in this case.

- Low noise insulation is insignificant, but still a lack of ceramic coating. Putting the floor with tiles, on top of the concrete screed, it is better to put a sound insulation layer in advance.

Laying of ceramic tiles do it yourself

Preparatory work

According to SNiP - building standards and rules, cladding of walls with ceramic tiles should be carried out according to the aligned and plastered base. If we are talking about the interior of the walls, it is better to give preference to the glazed coating, since it is characterized by greater decorativeness and better strength.

Before starting work, you also need to calculate the required amount of material. Studying the GESN, conducting cladding of the walls with ceramic tiles in his own house, is not at all, but it is still necessary to calculate the approximate costs of work. You can approximately find out the tile consumption in the following way: first should be measured by the total surface area, which will be separated by the material, and then divide the obtained digit to the dimensions of one tile. This indicator needs to be increased by 10% to create a small supply. To the cost of the tile, add the price of the required tools, equipment and consumables.

The preparation of walls is carried out as follows:

- First of all, you need to de-energize the wiring and drown all sockets, splitters and fittings in the walls.

- Painted walls are cleaned from the influx. If the surface is painted with oil compositions, it makes frequent horizontal and vertical notches.

- The plastered surface is tested for strength. Departed, swollen, shuffling places are knocked down and plastered again. All deep cracks, depressions, chips close up, screamed.

- Concrete or brick wall pre-plaster. You can simplify work and simply align the masonry, close the flaws, make notches and cover the surface with a liquid cement solution. For this, it is necessary to rinse the wall with water, then apply a solution on it by spraying, lift it with a rail or half-sash and give dry.

How to cut the tile on the part

In the process of work, you may need not solid tiles, and some of their fragments. For this, the material will need to be cut, and this can be done in the following way:

- On the front side, mark the feature on which the part should be divided.

- To this feature, attach a carbon or ruler. Swipe the glass cutter along the ruler, making a strong push.

- Turn over the tile to the back side and slightly catch it up.

- Rotate the item again to the front side up, put a cut on the rib of the table and hit the tile, the splits of it into two parts.

A more convenient way is to use a special cutter, but it is advisable to apply it when you need to cut quite a lot of tiles. If in the ceramics it is necessary to do round holes for outlets, you can use the electric drill with the nozzle "Ballerinka".

Wall Facing Technology Ceramic Tiles

To begin with, consider the process of laying tiles on a cement solution:

- Initially, the wall is tested with a plumb, apply markup on it and install beacons that will mark the levels of the facing coating. When fixing the beacons, you need to take into account the thickness of the solution, which is 10-15 mm. The step between beacons should be approximately 60 cm.

- At the edges of the walls, the slats are fixed, the length of which is 2 m, and the cross section - 4x4 cm. The horizontal cord will later be attached to these rails, noting the location of the facing.

- Tile laying can be carried out both from below-up and in the opposite direction. Before starting work, the material is plunged into the water for a few hours, and immediately before installation, each item is wicked again.

- Then there is a little solution on the tile and pressed it to the wall, slightly rotating in different directions. When laying the material, you need to follow, so that the edge of the tiles touched the stretched cord. The vertical of the seams can be checked with a plumb, and the waviness is a loyal rail. Each tile, laid on a fresh solution, it is necessary to slightly catch up, so that the solution evenly filled the free space between the wall and the facing.

- Forming even seams, special plastic crosses are inserted into the gaps between the tiles. When the laying is completed and the solution will freely freeze, the crosses are removed, and the seams are sealed with decorative mastic.

- At the end of the work, the facing is purified from excess solutions and wipe carefully.

Laying tiles for adhesive

Sometimes ceramic tiles are mounted using PVA mastic. This process is carried out in a similar way: the material is placed with horizontal rows and aligned along the rude cord. But there is in such work and its distinctive features:

- The surface of the primer is applied to the surface of the primer, the functions of which performs a 7% solution of PVA-dispersion. The primer layer should be approximately 1-2 mm.

- Then the wall is covered with adhesive composition using Halfury. The glue layer is smoothed, then the tile is applied to it. Each item is slightly closed with a wooden bar, so that the mastic is evenly distributed in all voids.

- The flattering of masonry is controlled by a plumb. The first row of tiles are installed on a reference rail. Focusing on the first row, the rest is mounted on the wall.

- Glue from under the tiles is removed with a spatula or spatula. So that the seams turned out to be neat, gaskets are inserted into them: plastic crosses, fragments of thick wire, wedges, etc.

- After soaring the mastic, the gaskets are removed, the seams are climbing with a solution, and the finished surface is washed from the remnants of the materials used.

It happens that ceramic tiles are put on special glue. Modern adhesive compositions have good adhesive properties and quickly grab. When using them, the tile does not need to be pre-soaked in water, and the seams fill in the tabs, as the parts are securely kept on the adhesive and not slip through the wall. The process of laying tiles on glue looks like this:

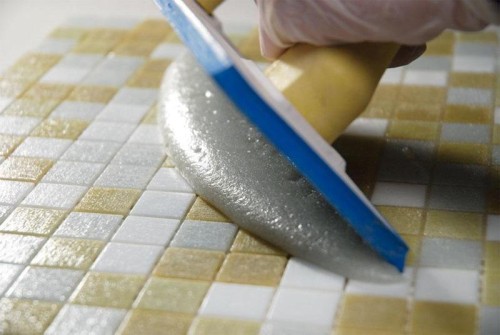

- With a spatula, the glue is applied to the wall of the wall with a uniform layer. Then the withk spatula is moving the mass, so that the final layer was not more than 3 mm.

- On the treated area glue tiles, observing the evenness of the rows. Each item is bold wooden bar.

Opening seams

The last step in the laying of the tile is the batch of seams. This procedure makes the lined surface visually more accurate and beautiful. In addition, it is possible to pick up the mastic of a certain shade to seal the seams, thanks to which the decoration wall will play with new paints. Special silicone sealants protect intercutric seams from mold and fungus, so they are often used in bathrooms and kitchens.

To give the seams of neat species, they are processed by a suitable tool, such as a piece of cable, a thin wooden wand of a circular cross section or a special device - extender. The tool is immersed in a fresh solution that is filled with interlocking space. All surplus and drips are immediately removed. The finished facing thoroughly rub with a wet sponge and wipe dry.

Facing walls with ceramic tiles, photo: