Moody floors - a coating that has long established itself as a reliable, high-quality, and having a long service life. Even modern building materials that gradually come to replace him, often cannot replace such an eco-friendly and good version.

Content

The main feature of the wooden flooring is that it justifies itself to almost any soil and in any type of room. This is the perfect decorative solution, easy care, the possibility of restoration and local repairs.

Wood suitable for flooring

Most often, boards made of coniferous breeds are used to arrange the agony floor. Thanks to their use, it turns out durable and wear-resistant flooring with a variety of advantages during operation.

Tree breeds:

- pine;

- spruce;

- fir;

- larch;

- cedar.

It is these breeds that have a very elegant structure of the fibers and may not be covered with paint. If you palate dense and light boards, you will get a brilliant floor with a natural tint. Over the same expensive and therefore prestigious species - oak, dark and light walnut, alder, mahogany - have a unique texture, but they can afford to not many.

Recommendations:

1. Regardless of which you use lumber for the facility floor, it should be well succeeded. If we raise the floor with boards that have an increased humidity or vice versa are too overproed, it will soon arise clearances, non-psychic slits and the warp warning will begin.

2. During the acquisition of building materials, see that it has been carefully processed by special antiseptic drugs, which warn on the occurrence of rot and fungus.

3. Before mounting the flooring from boards, lags and gaskets should also be treated with an antiseptic agent, and put mastic, paint and varnish on the front side.

4. To protect the floor covering from wood rodent insects, treat boards and lags insecticide in a paste-like state.

Types of wood floors:

- massive and parquet products;

- milled;

- unedged and edged boards.

In this case, the device of the boarding gear may vary, but the design itself most often remains the same:

- beams or lags;

- he himself flooring from the selected type of sawn timber;

- layer of paint or varnish.

Do it yourself

The high-quality technology of the device of platform floors is focused on certain climate conditions. It is best to start construction work in the summer season, after a long warm and dry weather, as well as at the end of the heating season. This is due to the fact that the tree has the property to absorb a large number of moisture from the air in the summer. Accordingly, such a flooring for the winter can disappear.

Staying of the female:

1. First, pre-marking should be made.

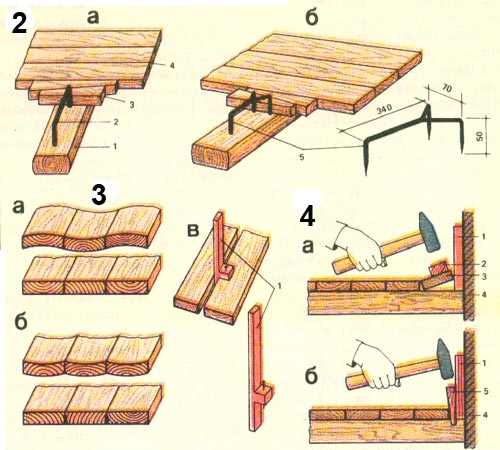

2. Wooden boards are put on the pre-prepared lags at an interval of 0.1 cm. In this case, end edges should not come into contact with the walls. The joints have a lag on horizontal faces. Staying of the female is created in different directions by annual layers.

3. Next, check the technological indents:

- between the inner walls and boards should be a distance of 10 mm;

- between the outer walls and boards - 20 mm.

Such a precaution allows you to protect the boards from the posting and moisture, which is transmitted by cold walls.

4. Then the possible defects are detected:

- chips;

- cracks;

- spots resinous;

- pollution and so on.

If you are detected not varieties, they must be postponed to arrange a rough floor or to discard.

5. Using chalk or marker, make the board numbering.

6. The first board is installed with the help of nails 10-12.5 cm. 2 nails are consumed on each floor, which are driven under a small angle on both sides. Hats should be flattened and drown in wood.

7. To the first half of the created label, two boards are applied to the label. The fasteners and scales of Smolyakov are driven into lags with a gap of 50 mm from the edge of the extreme floorboard.

8. In the resulting clearance, it is necessary to insert a prevention bar, which is located close to the edge of the extreme floor. In the same place the wedge is driven wide a little more than a gap between the bracket and the bar. Thus, the planning of boards is created, as well as tight pressed to each other edges.

9. Next, the boards are nourished on both sides and the brackets are removed. In the same way, the following one or two boards fixed.

After the surface is fully shown, the stocks are created. Small drops of flooring, which can be formed in the joints of the joint, eliminate the lining of rubberoid, cardboard or roofing.

The locations of the wall and floor covering must be closed by plinths or cartoons. You can also apply models with deposits and grooves, but in this case you should create a grid for ventilation on the floor surface. The most convenient option is a plinth, which is equipped with a locker. The optimal building material for such a detail is a coniferous tree. As for plastic products, they are not recommended to combine with wooden boards.

Floor-made in the apartment made of edged or unedged boards

Recommendations:

1. Installation of such a floor should be produced so that the annual rings have different directions. Such a flooring will provide an ideal surface and a rather pleasant drawing.

2. If you are using edged boards, they need to be shifted from the front side and sfig. This type of flooring is carpentry, as it allows the boards enough to feel tight towards each other.

3. In the installation process, the first board must be mounted at a distance of 1-1.5 cm from the wall. Then, with the help of the brackets are as follows. Wedges are inserted between the boards and the wall.

4. The last board is selected in width and mounted using a laying and a small hammer tapping. After the flooring, all the boards are fixed to the base of nails.

Milling Board Board Scheme

Milling boards - wood products that are produced by the factory way. They have a groove and a comb, located on the opposite sides. Their width is 7.4-14.4 cm, and the thickness is 2.8-3.6 cm. This type of flooring is sufficient simply installed, and in order for the boards to be densely adjacent to each other, they are combined with a small bevel on the front side.

Progress:

1. The first board is put in a groove to the wall with a small indent.

2. Nails are clogged into each beam (lag), and the caps are cut down by 0.3-0.5 cm.

3. Upon completion of the work, the resulting traces are covered.

4. The second board is applied to the first, then they are compressed with brackets or wedges. After that, fixed by nails.

Double boat floor

If your home is located on a problem ground, you should create a draft wooden floor and lift it above the ground by no less than 50 cm. And the space that is formed between the black and clean floor is filled with thermal insulation.

Floor design from top to bottom:

- coating chisty;

- insulation;

- beams;

- waterproofing;

- brick columns;

- concrete screed;

- clay soft;

- soil rambered.

Progress:

1. Wooden paper shields are fixed to beams.

2. The shield surface is covered with clay lubrication or rubberoid.

3. The slag, clay granules, mixtures mixed with lime or tiled insulation are used as thermal insulation.

4. From above, the rubberoid or pergamine.

Installation of the first floor:

1. The installation is carried out on the top of the beams.

2. The corners create ventilation holes.

3. The direction of the piston version of the board is determined in the direction of movement, or in the direction of light.

Grinding outdoor coating

Grinding allows you to eliminate chips and irregularities of the onset lumber.

Stages of work:

- first, clean the floor from the garbage and check that the hats of nails drowned in the boards;

- then you need to wash the surface with soap water and dry;

- next, grinding grinding with a special drum device;

- corner type of machine will allow to process corners indoors and hard-to-reach areas;

- thin grinding is performed by special equipment with small skins.

Lacquering and floor staining

Stages of staining:

- after careful grinding, the surface of the vacuum and ground;

- next, with a sprayer, brushes or roller, paint is applied in several layers (each subsequent layer must be completely dried).

Stages of varnishing:

- after careful grinding of a wooden coating, the surface is cleared of dust;

- then with a soft brush or roller along the fibers are applied with a lacquer layer;

- the first layer should not be done very thick;

- the second layer is applied after a few hours or a day;

- optionally, varnishing the third layer is allowed, however, before it is applied, the surface should be pulled out by a cell.

Wooden floor arrangement on videos lags: