Chimney is the most important element of the building engineering equipment. They are needed not only when equipped with furnace heating, but also when creating wood stoves, fireplaces that connect to them are derived to the roof. Most often, the chimneys are equipped with ceramic bricks, but under the action of high temperatures and other factors, this material will eventually begin to collapse, which worsens the traction and combustion products fall into the residential premises.

Content

Modern chimney systems can prevent such a situation, which, on operational characteristics, far exceed traditional bricks:

- from heat resistant ceramics;

- of steel;

- stainless steel, etc.

At the same time, they consist of modular standard elements, convenient to assemble and during transportation.

Chimney functions:

- ensuring the necessary thrust;

- retraction of smoke from the heat chamber.

Thus, depending on the used building materials, as well as the design of the chimney, it is possible to significantly increase the efficiency coefficient of the heating system and reduce the risk of fire formation.

Chimneys for boilers

Modern heating boilers have a fairly large efficiency, so after using heat of combustion products, they are eliminated and favorable conditions for the occurrence of condensation are formed.

The chimneys presented at the homewater have certain advantages and disadvantages, respectively, their choice should be based on the architectural features of the structure, knowledge of the technical characteristics of the system, the preferences of the consumer, etc.

Types of boiler chimneys

In the form of the lumen there are:

- rectangular;

- square;

- round.

The round variant of the chimney is less inclined to accumulate soot, has excellent traction and has good aerodynamic characteristics.

Types of round chimneys:

- coaxial chimney (pipe in a pipe) - It combines the function of supplying fresh air into the combustion chamber and the function of smoke removal;

- sandwich chimneys - a double tube, the space in which is filled with insulating material;

- single - created from stainless steel and have a type of pipe.

Materials based on chimneys:

- from asbestos-cement pipes;

- from glass;

- from chamota (ceramic chimneys);

- of steel;

- from brick.

Chimneys from Steel

Fir-resistant metal steel pipes are designed to change this material outgoing in the past as a brick.

Advantages:

- ease of assembly;

- the possibility of mounting in buildings in which the heating system was not originally expected;

- small specific weight.

The system of such a chimney resembles a constructor, the components of which are firmly inserted into the grooves, are summarized to the heating unit and are fixed on the outside of the house. Thanks to the round shape and smooth inner walls, the maximum thrust is provided and there is no sediment inside the soot.

Stainless steel chimneys

This modular chimney includes:

- umbrellas;

- headplains;

- tees;

- swivel elements;

- pipes, etc.

Chimneys that are produced from stainless steel sheets have a thickness of 0.5-1 mm.

With such a variety of components, it is possible to collect systems absolutely any configuration.

Advantages:

- the diameter of the chimney can be from 8-20 cm;

- thanks to the rapid heating of the walls, a good traction is installed;

- durable;

- the walls of such chimneys have good strength, which allows you to carry your weight even at a small height of the structure;

- due to the presence of a circular cross section, a quick removal of combustion products occurs;

- easy to clean;

- resistant to temperature differences.

Types:

- bonded;

- single.

Ceramic chimneys

Such chimneys are made from fire-resistant building materials - ceramics of refractory or chamot. Channels from ceramics are mounted into special shells from porous concrete, which give the design stability and serve as wonderful heat insulation.

Advantages:

- eco-friendly;

- durable.

Chimneys Sandwich

This type of chimney is similar to the Russian Matrychka - the small pipe is inserted into the largest, and the insulating system is stacked between them. However, during installation work, you should carefully treat the connection, since the flange is much more complicated than bayonet. By virtue of its fireproof, such chimneys are the most optimal for wooden buildings.

Gas chimney

Such chimneys are equipped with a modular design and are made of good quality steel, which is resistant to moisture, high temperature, aggressive environmental impacts and acids. They are pretty simple in installation and operation, and also provide effective operation of the heating system.

Views:

- double-wall;

- single flexible;

- single.

Installation of chimney

The installation of a workable, reliable and correct chimney involves high-quality design, which provides the normal functioning of the tap channel for a long amount of time. The diameter of the chimney and its height should be determined in accordance with the parameters of the fireplace insert, furnace and boiler, so during the creation of the project, the following requirements must be taken into account:

- in a heated building, a non-insulated pipe for chimney can be used, but the "sandwich" should begin at least 60 cm before the overlap;

- it is forbidden to pass uninsulated pipes through overlaps;

- chimneys that pass through the non-heated attic should be insulated;

- the height of the chimney should be from 5 m;

- it should be created the correct ratio of the force of the thrust, the diameter of the pipe and height;

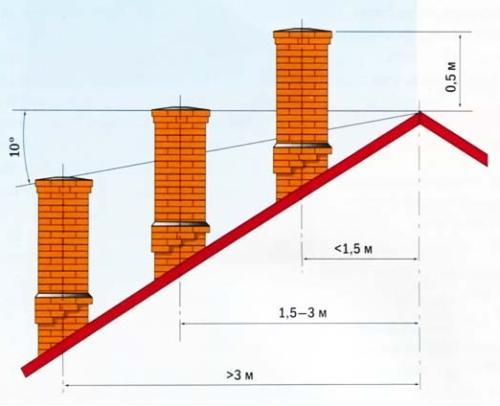

- the ratio of the protruding elements, the skate of the building, ventilation channels and the height of the pipe should also be optimal;

- joints should be located outside of inter-storey overlaps and be available for inspection;

- fix the pipe to the wall, in front of the angular tap and after it, you need with the help of a clamp in 150-250 cm increments;

- those pipes that protrude above the surface of the roof of more than 120 cm are attached with stretch marks;

- wooden surface must be treated with antiprens;

- during the passage of the 'sandwich' overlap through use of steel plate with holes and not amenable to combustion heat insulation;

- if there are several furnaces, they are recommended to ensure independent chimneys;

- if you create a painting, it should produce a heat-resistant enamels.

Design and installation of modular chimney

Preparation:

- initially need to define a vertical flue passage of the shaft in accordance with all the guests;

- then must prepare for all mounting elements by clearing them from the film;

- ready tools.

The configuration and location:

- the smoke channel must have a vertical position without any narrowed;

- be not more than 2 deviations from the vertical at an angle of 300 and refers to 100 cm Exceptionally acceptable deviation of up to 450, and include - up to 170 cm.;

- if the length of the connecting flue above 200 cm, it must be equipped with a revision, at a length of 300 cm - should prepare a technical report that extended horizontal portion will not affect the traction;

- furnace flue coupling length must not be more than 100 cm;

- flue height of the grate of the heat generating unit to the mouth of the tube should be between 500 cm and smaller height is permissible only in buildings without an attic.

Types of passes:

- through the wall;

- through the ceiling overlap;

- through the roof.

Passage through the roof:

- first on the roof should be noted location and size required for the passage of the pipe;

- then cut opening;

- further in using a mineral wool insulation should insulate roofing construction materials in places the passage of the chimney;

- then the modular element is inserted into the hole of the roof;

- roofing basis closed all the holes;

- above the cone on the tube set apron;

- the edges of the roof is slid under the horse.

Caring for the chimney:

- at the end and beginning of the heating season should be checked for leaks masonry joints of the bricks, the joints modules, traction;

- if necessary clean the soot;

- inspect the furnace flue compound;

- in that case if the chimney has not been used for a long time, in front of a fire, open the door tee and make sure that it is not clogged.

Installing a chimney for the fireplace video: