Modern materials intended for facing the outer part of the building are elevated requirements in terms of resistance to the negative impact of natural factors. But not only makes them in demand. When choosing a finishing material, his attractive appearance plays his attractive appearance. One of the materials that meets the above requirements is siding.

Content

What is a facing material

Siding consists of separate panels, each of which includes the perforated edge and lock-latch. In appearance, the cladding of the building by siding can be compared with the boardwalk, since in most cases the material is similar to natural wood.

Dimensions of panels are different. They vary within the following limits:

- length - 2-6 m;

- width - 0.1-0.3 m;

- thickness can reach 10 mm.

Among the characteristics of the siding should be allocated:

- environmental safety;

- resistance to mechanical damage;

- preservation of the initial type and properties throughout the entire operational period;

- easy of installation and care.

There are several types of siding:

- vinyl;

- base;

- metal;

- wood;

- cement;

- ceramic.

The most demanded material is vinyl siding. We will tell about the peculiarities of its application in the instructions for the installation of siding with their own hands.

Creating a crate

At the initial stage, careful preparation of the surface of the base is carried out:

- in the presence of plastered walls, all supling plaster is removed;

- when weaving wooden walls, a replacement of rotten wood and feeding the retired boards;

- all protruding windowsills and lowers are removed;

- drainage pipes, lamps and moldings are removed.

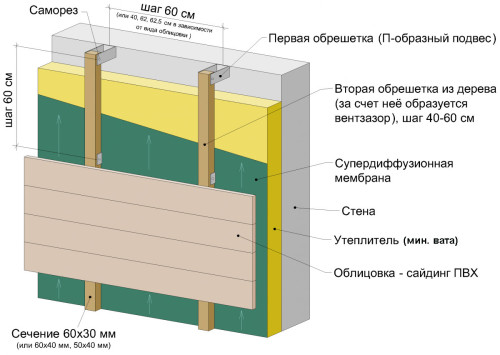

Only after the preparation of the walls you can proceed to the device of the crate. For these purposes, galvanized galvanized profiles are used for drywall or wooden rails. Regardless of the material selected, the main requirement is that the framework must be mounted perpendicular to the siding panels.

According to the instructions for installing vinyl siding when creating a crate, such requirements should be followed:

- between the facing material and the house wall leave space for air circulation;

- the fastening step is 0.3-0.4 m;

- the siding panel on the edges should be adjusted to two adjacent rails;

- the facial part of the crate elements is located in the same plane;

- reiki must come into contact with the surface of siding without distortion;

- corners of the house, window and doorways are covered with rails around the perimeter;

- work on the device of the crate begins at the bottom of the wall, and ends on top.

Warming construction

In the process of the framework of the framework, thermal insulation works can be carried out. The insulation is better to use mineral wool. The foam deficiently disappears, which is able to delay moisture and prevents the "breathing" of the walls.

The process of surface insulation provides:

- cutting the harvesting of heat insulating material;

- laying mineral wool between slats;

- drilling holes under the dowel;

- fixing the insulation with umbrellas.

After laying the insulation, the installation instructions for siding involves the creation of a vapor insulating layer:

- a desired piece of vapor barrier film is cut;

- it is screwed to the places of contact with the profile;

- this is done with screws that have a wide hat;

- film strips are attached to the mustache (moisture should not get to the insulation);

- the joints of the vapor barrier are sick with scotch;

- on top of the film, wooden planks 2 cm thick are screwed;

- the space between siding and vaporizolation should be ventilated.

Fastening accessories

To secure the siding panels to high quality, it is necessary to correctly install the appropriate accessories (starting strip, corner strips, J-profiles for doorways and windows).

First, the starting strip is installed:

- the bottom point of the trim is determined;

- 1-2 mm above this point is driven by a nail;

- at the level of this nail robbed nails in the rest of the corners of the house;

- on all walls, flat lines are fighting off (the correctness of their application is checked by a construction level);

- the starting strip is attached to the wall (its top edge is located on the lines made);

- if necessary, the attachment of the adjacent starting strip is made at a distance of 7-10 mm.

The angular planks are designed to close the end edges of the siding panels converging at the corners of the house. They are attached with the help of nails, which are clogged in the center of the holes at a distance of 0.2-0.4 m from each other.

If there is a need, the planks can be knocked out. For this, 2.5 cm is cut off the side part from the top edge of the bar (in no case cannot be trimmed by the central part). The imposition of the subsequent plank is carried out with the presence of a gap to 0.5 cm. Thanks to the gap, the deformation of the material is prevented during temperature differences.

J-strips are used to edge door and window openings around the perimeter. When installing this accessure, the main problem lies in the correct formation of angular joints of horizontal and vertical slats.

The fastening technology of J-slats involves the following actions:

- a horizontal plank is taken, which will be mounted above the window opening;

- at its bottom, on the one hand, the "ear" is cut out up to 2 cm long, which bends into the lower part;

- the same procedure is carried out on the other side;

- the front bent part of the bar cuts up at an angle of 45º;

- in the side bar on the bottom there is a rectangular cutout (its depth is 2 cm);

- there is a connection of lateral and top planks;

- the final fixation of the slats is carried out (a nail is nailed in the center).

Installation of panels

In most cases, the installation of siding is produced in the bottom upward direction:

- the first panel is taken;

- her lower edge is laid behind the protrusion of the starting plank;

- the top edge of the panel is nailed to the crate;

- the fastening of the second row panels are engaged only when laying the first row.

Installation of panels is carried out in such a way that they stood freely. They must move from side to side. If this is not done, the deformation and trim damage can occur as a result of the temperature difference. In addition between the end part and the vertical fittings (J-strips, corner bar), the gaps of up to 6 mm are necessarily left.

In the process of carrying out installation work, you can encounter such a problem as the excess of the length of the wall of the house above the sizes of the siding panels. In the length of the panel in length can be one of two ways:

- By installing the docking n-molding at a specified location.

- By laying a cladding material of the brass with the overlap of panels by 2-3 cm. The joints of the joints are locked.

After fixing the last panel, the finishing plank is installed. The edged part of the panel is snapped into the groove of the finish plank, and the plane itself is flush with a cornice in the top of the wall.

Features of the installation of base siding

The technology of installation of base siding is largely similar to the cottling of the house with vinyl material. Its main stages are also:

- preparation of the foundation;

- creating a crate of out galvanized profile;

- fastening panels.

Instructions for the installation of baseline siding provides for the fulfillment of the requirements that are presented to the fastening of a material made from vinyl:

- Siding is fixed to the crate is not too tough. The clearance ensures the safety of the material with thermal expansion.

- When installing work on a cold day, the gap between the panels should be within 9-11 mm, in the warm time - 6-8 mm.

- Screw the screws (lifting nails) only in the middle of the mounting hole. Otherwise, with a strong heating, siding will burst.

Distinctive features of fastening technology of baseline siding are associated with increased requirements for waterproofing the surface of the walls. With close grounding ground and in the northern region, laying an additional layer of waterproofing material will be required before mounting.

In most cases, polyethylene film is the waterproofing material. Although it is possible to use special mastic, which includes moisture-resistant resins.

If the foundation humidity at a depth of 3-5 cm exceeds 4%, then this can lead in the future to the deformation of the skin. For this reason, in addition to the waterproofing material, the base is processed by the primer-antiseptic of deep penetration, which will not allow the appearance of fungus and mold.

Useful advice

To implement high-quality siding installation, the following technological nuances must be observed:

- When working in cold weather, the material must be ruined 10-12 hours in the warm room. So the panels will become more flexible.

- When connecting the adjacent panels, it is forbidden to press them hard or stretch. Siding must maintain a natural state.

- Nails are clogged only at right angles. The presence of only one bent nail can be a hindrance for normal displacement. What will immediately lead to the "bloating" of siding.

- It is impossible to engage in the sealing of the joints of the panels in places that come into contact with the corner profiles and J-strips. If siding is increasing, then the connections are also not necessary to process the sealant.

- When installing short panels (for example, between window openings), it is not necessary to immediately navigate the vertical J-strips. When inserting panels, they will need to be slightly flex. The final fixation of the J-slats is carried out after installing short panels.

- When installing platbands, an electrical cable and other elements of the hole in siding make such that their diameter exceeds the size of fasteners by 5-7 mm. Only so siding will shrink without any problems and expand at temperature fluctuations.

- Mounting siding without a framework device is allowed only in one case - when a new house is built of wood or walls are trimmed by plywood, dvp, chipboard or similar materials.

Special attention should be paid to the correct cutting panels:

- for these, it is better to use the electric bike or a grinder;

- when cutting off the panel from the length, 1 cm should be deducted (the material is heated and expands slightly);

- measurement of each subsequent panel is carried out after installing the previous one;

- cutting material is allowed only in the upper part, where perforations are located.

Video instructions on siding montage: