The available options for finishing the facade of the building are currently quite a lot: from banal plaster to high-tech ventilated systems. One of the latest construction in the field of construction has become composite materials for the arrangement of ventilated facades.

Content

What is composite panels

This design, in contrast to insulation, polystyrene foam has several advantages:

- The durability of the insulation, due to the removal of excess moisture.

- Fire safety due to the use of non-combustible materials.

- Excellent heat and sound insulation.

Among the disadvantages of ventilated facades, you can highlight the high price of materials and the complexity of installation.

For the arrangement of ventilated facades use a wide range of materials:

- siding,

- wooden lining,

- composite plates.

The latter appeared on the market relatively recently, but they rightly deserve popularity as among builders and among the consumer. The sphere of using composite panels is quite wide, but most often they are used to finish facades. About how the composite plates are used in construction, let's tell you further.

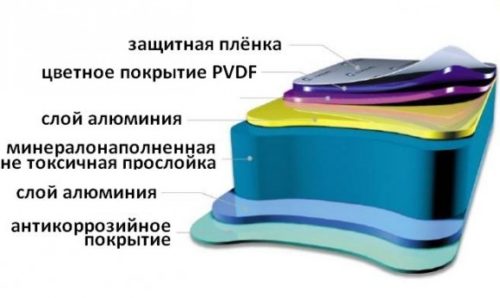

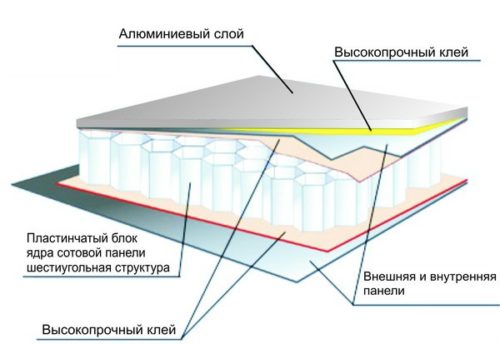

So what is the composite plate? A composite aluminum panel is a layered material consisting of three main elements: two sheets of aluminum alloy 0.2 - 0.5 mm thick and an average layer, which is a mixture of polyolefin-based polymers. Thanks to this structure, the panel has quite good performance characteristics, which allows it to be used both as finishing and as structural materials. For finishing the facades of high-rise buildings, composite panels are used with a thickness of 4 mm with a thickness of an aluminum wall of at least 0.5 mm.

The technology of manufacturing composite panels of the structure does not constitute anything complicated. At the beginning, the roll of fine aluminum is rolled and subjected to cleaning and coating with a layer of paints and varnishes. Next, a layer of polymers are applied to the inner surface of the sheet, after which 2 sheets of polymer layers are bonded into one. In this case, a high temperature is used, which ensures reliable sintering of two halfs to one panel.

Advantages and disadvantages of facade composite panels

The advantages of composite panels in the facade finish:

- Installation on the frame from the guides. Due to this, you can not align the walls to the perfect surface.

- Wide range of colors. Each of the manufacturers of composite panels has at least two dozen different colors and shades in its assortment. When ordering a large batch, for example, for finishing a large office building, it is possible to select the color of the panel. Thanks to this, the building exterior can be performed in any color, including corporate colors.

- Large service life. Due to the composition structure, as well as the use of aluminum in the production of such panels, they have excellent strength, do not affect moisture, and a special protective coating protects them from burnout in the sun. In addition, unlike plaster, such panels are easily clean, which is very important if the building is in production or in a dusty area.

- Excellent noise and thermal insulation. Moreover, when installing the ventilated facade on the basis of composite panels, these indicators are increased several times.

- Easy installation. Composite panels are very easy to refine on the installation site. They are just enough to bend, giving them the necessary form. During the work of work, no mixing of adhesive solutions is not required: everything is performed quickly with structural materials.

- Wide selection of composite panels for home. This allows you to apply panels for any type and size of the building, from a private house and to high-rise buildings.

Of the disadvantages of composite panels, they can be distinguished by a fairly high cost, which stops many in the selection of this material. However, according to experts, investment in such facades will pay off rather quickly.

Install decorative composite panels on the facade

Due to the absence of "wet" processes, as in the case of a polystyrene facade, the installation of a ventilated facade based on composite panels can be performed at any time.

Procedure for work:

- First of all, before starting work, it is necessary to mark the places where the brackets for fastening the framework will be installed. To do this, use the geodesic shooting of the building. By its results and mark the markup. If it is planned to install a ventilated facade only on a part of the building wall, for example, when insulating one apartment, then geodesy can not be carried out.

- When placing the wall, it is necessary to clearly output the horizontality and verticality of the lines in the level. Deviation vertically and horizontal will significantly work out the process of mounting the frame. For ease of work, you can use a laser level, and the mounting points of the brackets is better to combine the painting cord.

- Fastening brackets is made on anchor bolts. Their length and diameter must comply with the instructions on the installation of composite panels from the manufacturer. Otherwise, the mount may not withstand their weight and fall off. This is one of the ways of connecting composite panels.

- When attaching the brackets should be aware of the possibility of thermal bridges. The fact that the aluminum panel and steel profiles have a very good thermal conductivity, thereby, to the junction of the wall system will be delivered cold. To avoid this, the bracket is enclosed by a special seal that will prevent the transition to the cold wall. Particular attention should be paid to the length of the bracket. It depends on the insulation thickness. It should be enough to get between the insulation and the guide, which will be attached to the panel, there was a backlash air movement.

- If the arm is too short, a special console (Extension) is attached to it. He is simply inserted into the bracket and fixed with aluminum rivets. For this operation, you need a special tool (Riveter).

- Once the brackets are set, it is possible to start mounting the insulation. Typically, these studies used the glass or mineral wool. These materials have excellent thermal insulation properties, do not burn, do not give in to water. Some models of mineral wool have infrared reflective layer.

- Insulation can be strung on a fixed bracket, then strengthened by means of special dowels - fungi. This name they received due to the cap of large diameter. Dowel inserted inside the nail, which is bursting with it inside, not allowing to get out of the dowel holes.

- Drilling holes through the layer of mineral wool is quite problematic. Its fibers are wound onto the drill quickly, thereby contributing to the destruction of the material. The solution to this problem is quite simple. You will need a tube with a diameter of 2-3 mm larger than the diameter of the drill. It is inserted through the heater close to the wall and through the drilled hole.

- Once the heater is attached to the wall, you can begin the installation guide. They are attached to the extension of consoles by the same rivets. When fixing the guide should be strictly checked them vertically and horizontally. Only in this way it will be possible to achieve normal attachment panels themselves.

- When the vertical guide profiles are mounted, it is possible to start mounting element, which only applies when working with aluminum composite panels. This spacers slide. They are necessary to the panel more tightly against the guide. They attach to the rails rigidly fixed by rivets.

- The next step must be combined with drainage profiles with carriers (vertical), thereby finally forming a framework.

- The last step is attached panels. They are simply inserted into the spacer salazzas on the crate and attach to the profile along its entire length.

Processing composite panels

When installing composite panels, there may be necessary to be machined: cutting, molding, milling.

Cutting the composite panels can be frosic and hacker saws. It is necessary to control the speed of the cut. It should not exceed 5000 rpm. For milling panels, cutters with a head of high-speed steel are used. The frequency of its rotation must be no more than 3000 rpm. Code of composite panels can be as shaped mills, and disk. The first are most suitable for hand mills.

The drilling of composite panels is made by conventional radial drills for metal. The most preferred material from which the drill is made is the high-speed steel.

The bending of the panels is performed in the same way as the conventional steel sheet. This does not require special equipment. In order not to damage the surface in the process of bending, it is necessary to use gasket materials, such as foil or polyethylene thickness 1 - 1.5 mm.