Mosaic is a finishing material that is used to create original images and is an alternative to painting. With it, you can decorate both the facade of the building and interior. Using a mosaic, you can create a panel pattern, as well as perform a solid surface cladding forming a chaotic image, where contrast elements are located in a basic color background.

Content

Features of sticking mosaic

For convenience, decorative mosaic passes on a paper or mesh base. Laying is performed by the web, which makes the procedure more convenient and significantly makes it easier. Mosaic is manufactured in two ways:

- The first is the manual execution method. This method allows you to adjust each element under a certain place in the picture of the type of material, color and texture. But this manufacturing takes quite a long time. In addition, the finished product is quite expensive.

- The second method of manufacture is carried out using machines. The product thus obtained is distinguished by relatively simple patterns. But at the same time it is more affordable, since its value is significantly lower.

One of the positive properties of the mosaic of decorative type is aesthetics, because The seams during the docking of the elements are practically invisible. In addition, the mosaic is characterized by the manifold of drawings and patterns, which allows you to form a unique image. This type of finish is resistant to mechanical impacts, moisture, does not require special care. Mosaic is distinguished by the simplicity of laying, it will not be difficult to put both on a flat surface and on the surface having deformations.

Varieties of material

Mosaic is divided into species in two criteria:

- based on materials used as raw materials for manufacture;

- at the destination.

Depending on the materials distinguish the following types:

- Ceramic mosaic, which differs from ordinary tiles only by parameters. Today on the market you can find a large selection of shades and textures of this type of cladding. The mosaic of this type can be performed in the form of a square or rectangle. The texture is also diverse:

- inhomogeneous structure;

- glazed surface;

- small cracks;

- two-color mosaic.

- Mirror mosaic is made of small fragments of mirrors. But it is not necessary to fear its use. Thanks to the special processing of the edges, this material is completely safe in use. With the help of such a mosaic, you can create a creative and exclusive interior. The scope of cladding is small rooms where the lack of natural lighting is felt. For example, a bathroom or an entrance hall. In addition, the material from the mirror will help hide the irregularities of the wall.

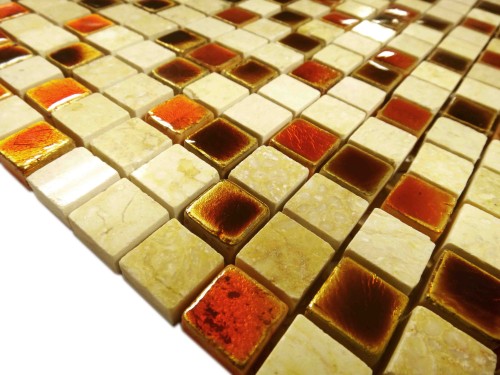

- Mosaic from natural stone. As a starting material for such a cladding, tuffs, yashma, sandstone, marble are used. The material is made round or incorrect shape. Due to the fact that it is almost impossible to find two identical pebbles, this kind of mosaic allows you to create a fairly unique finish. Stones are convenient to handle, they are easily amenable to polishing or an artificial aging procedure. The most widespread use of this mosaic as an outdoor coating. Using this finishing material, floors and garden tracks.

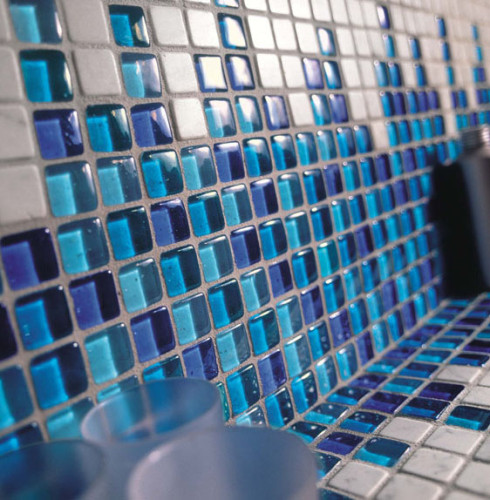

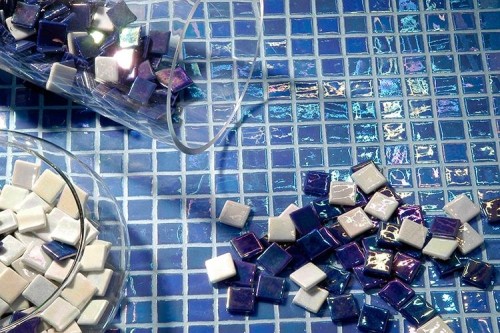

- A mosaic based on Venetian glass has a special aesthetic effect. It has a huge variety of shades. Such effect is achieved due to the presence of such components as selenium, pearl and cadmium. The coating made of this mosaic has enough long-term operation and is resistant to various aggressive effects. This coating is used both for wall and floors and for the scenery of fireplaces, furniture, interior items.

- Another material that is widely used to obtain a mosaic is a smalt. This is a glass that has passed a certain processing. The material is treated with oxidized metals, after which heated to a high temperature. Due to such processing, the mosaic acquires good performance:

- high resistance to mechanical damage;

- low temperatures resistance;

- wear resistance.

The mosaic of this species has a special visual effect - the refraction of light. As a result of granite or marble mixing technology with mirror glass, mosaic fragments are formed with an internal flicker effect. This coating has a number of positive properties. Such cladding is durable, is quite strong, has an attractive appearance. This material is used as an outdoor and wall covering for premises of various purposes, pools and staircases.

Technological features of laying

If you set out the purpose of decorating the dwellings or interior items with this facing material, it is necessary to find out a number of features of PVC panels mosaic: how to glue such a cladding, which composition you need to pick up and how to care for mosaics. So, consider the more detailed question of sticking decorative material.

For work it is necessary to prepare:

- toothed spatula;

- epoxy adhesive;

- knife;

- putty knife;

- nippers;

- ironing rubber press;

- tile grout.

The process of sticking is as follows:

- Work must be performed on a clean and dry surface. Therefore, before glue a mosaic, the base should be cleaned from the existing pollution and sharpen.

- Next, with the help of a spatula on the surface, a layer of adhesive composition is applied. It must be remembered that the adhesive dries quickly, so it is impossible to apply it to the entire surface immediately, it should be processed at one time only a small part.

- Then you can proceed directly to the laying. Tile sheets do not need to handle glue. After applying glue, the mosaic immediately stacked on the base. At the same time, it is necessary to place the material with a paper side up. To ensure a dense grip, the material is pressed through an ironing press. This will remove air bubbles between glue and mosaic.

- After the first element is glued to the base, you must apply marking. This will provide even lines between fragments. In the process of work, it is important to take into account the moment that the mosaic after drying has the property. In particular, this refers to a large material. Therefore, before glue a mosaic on the wall should be performed at the bottom of the double gap. In this case, the mosaic as a result of the effect of its own mass will take the required place.

- After 20 minutes, you can remove the paper sheet from the mosaic surface, because During this period of time, glue will already dry. For this, the sheet must be pre-mixed with water, after which it gently wipe the surface with a wet sponge. It is necessary to do it carefully not to shift the glued mosaic.

- After the paper sheet is soaked in moisture, we remove it with a slow motion. The direction of movement should be from the upper portion to the bottom corner. Performing laying must be monitored so that the seams between the elements were smooth.

The final stage in the question of how to glue the panel of the decorative mosaic is grouting seams. But before you go to it, you need to wait 2 days to glue completely dry. Previously, remove the remnants of glue and paper from the surface of the mosaic. This process is performed using warm water.

Grout is applied in a diagonal direction by ironing press. After 15-20 minutes, the mosaic should be wiped with dry soft matter, and after walking along the material with a wet rag or sponge. After another 15 minutes, the mosaic is polished with dry tissue. It is necessary to process all the coating at once, in the reverse case, the raid will not be removed subsequently.

Adhesive mixes

Choosing on what glue to glue a mosaic, it is necessary to take into account the features of the main manufacturers of compositions:

- Litoplus K55. This adhesive is used both for internal and external facing. With it, it is placed ceramic, glass and stone mosaic. Before use, this mixture should be breeded with water, after which it acquires an elastic pasty state and high adhesion qualities. Since white cement is present in the glue, the mixture has white. For this reason, it is not recommended to apply it to work with a transparent, mirror, as well as color mosaic. The glue of this brand is particularly convenient for cladding vertical surfaces, as the material firmly fixes and prevents it from slipping. It has environmental safety, resistance to low temperatures and moisture effects.

- Ivsil Mosaik. The main component of this mixture is white cement and polymer impurities. It is used primarily for laying a mosaic of white marble, glass, ceramic granite and tiles. Applied to concrete, gypsum, brick bases, as well as on the old tile. It is characterized by such properties such as frost resistance, elasticity, resistance to moisture, high adhesion.

- Unice BelFix. Used to work with marble, ceramic and glass mosaic. Suitable for facing vertical and horizontal bases. In addition to fixing the material, the composition can also be used as grouting.

- LitoElastik - suitable for both wall decoration and for laying outdoor coverage. The mixture can be applied to work with any base, in particular with plastic, glass, wood, metal.

Conclusion

Mosaic is a decorative finishing material that has unique aesthetic properties and allows you to create an interior in any style. In addition, decorative facing is characterized by a number of operational advantages, among which there are durability, resistance to mechanical damage, and moisture, as well as the simplicity of the styling process. The article addressed the features of how to glue the mosaic panels, and also shows the characteristics of the adhesive compositions.

How to glue a mosaic. Video: