It is quite difficult to exaggerate the value of concrete in modern construction. Using it at various stages of the building of the building, starting with the creation of a foundation, ending with the final work of a decorative nature of the landscape of a green zone near the house.

Content

- What is concrete?

- What is concrete?

- What are the main ingredients of the solution?

- Criteria for selecting concrete components

- Marking concrete

- How to make a concrete solution?

- Preparatory work

- Concrete standards

- Conditions for cooking

- Manual solution manufacturing method

- Capture concrete mechanically

- Video preparation of concrete mix

- Conclusion

What is concrete?

In its physical properties, concrete is an artificial stone prepared from a certain set of components.

What is concrete?

All components are divided into four groups in accordance with the principle of the component action:

- binding basis

- liquid mixing

- aggregate

- additional substances.

Important! The materials of the latest category are used primarily when laying concrete in difficult conditions or at the request of the manufacturer.

What are the main ingredients of the solution?

To create a concrete mix, prepare:

- Water

- Cement

- Sand

- Crushed stone.

Important! The building materials market presents a wide range of dry concrete mixes, which are enough to dissolve with water exactly with the instructions. But, cooking concrete with your own hands, with properly selected components, is also not difficult.

In the process of choosing the finished construction mixture, be attentive to the presence of specific additives. Some of them affect the frost resistance, the speed of solidification, the degree of plasticity of concrete.

Criteria for selecting concrete components

Water

In the production processes for the preparation of concrete mixture, water is used, the composition of which correspond to the regulations of the GOST. With independent manufacture, prepare drinking water.

Important! Check the quality of the water, it should no alkali, sugar, oil, acids and other impurities.

Cement

The general name of the binder, the basis of which is merghelistic, lime, clay rocks. Most often, portland cement is used in construction, with a high percentage as part of calcium silicates.

Cement classification:

- No additives, that is, their content in the composition does not exceed 5%. Marking "To" or "Sem I".

- With additives, the percentage indicator of which varies in the range of 35. Marking d + The indicator of the content of additives in percent, for example, "D15" or "Sem II".

When buying, pay attention to the following nuances:

- a permissible use of the mixture

- storage conditions

- make sure that the level of humidity is properly, that is, the cement is not refunded

- check the flowability of substances (it should not be parted, compressable)

- make sure the appropriate marking on each bag

- the cement brand must exceed the brand of the planned concrete (see this below) by 2-3 times.

Important! Do not buy cement too early, quite enough for 1-2 weeks. In case of failure to meet the timing and storage conditions, it loses quality, which will affect the strength characteristics of concrete.

Sand

The selection of sand has its own conditions and requires the right approach.

Pay attention to the following points:

- The size of the granules. There are several species, the size range of which varies from 1.2 to 3.5 mm. Prefer large sand.

Important! Consider the smaller the granules, the more sand consumption in the manufacture of a concrete mix and a smaller strength of the finished hardened composition.

- Purity matter. Use the maximum clean material without impurities and dirt (particles of plants, sludge, clay, glass, soil, dust). Check them with sifting or washing sand.

Important! This criterion affects degree of grasp., Cement consumption for concrete and water.

- Fruit. The sand should be well dried, not wet, as the number of dry matter is in recipes.

Important! In any state of the sand, it presents a certain percentage of absorbed moisture, which is usually taken into account when drawing up proportions of substances. In dry - this indicator does not exceed 1%.

Crushed

Pay attention to the following criteria:

- The quality of the material. Three main types are distinguished:

- The size of fractions. The largest fragments should be within 150 mm.

- Form rubble. Cuboid fragments will provide greater strength.

- Purity. Pay attention to the absence of dust and other contaminants.

Important! If nevertheless, the crushed stone is not very clean, be sure to remove all the extra particles before observation.

- Brand Take rubble with an indicator 2-3 times higher than the specified brand of concrete.

Important! Consider, most often, the quality of the rubble affects the strength of concrete.

Ceramzit

This material does not apply to the main components of the concrete, but to create a lightweight solution (in order to reduce the load on overlapping and frame design) quite often use clay instead of rubble.

When choosing this material, pay attention to:

- fractions size - from 3 to 5 mm

- fruit substances

- clean and homogeneity.

Marking concrete

Classification of concrete is performed by:

- class (B)

- brand (m).

The concrete brand indicates compressive strength and permissible load. Indicators vary from 50 to 1000 kgf / cm2. That is, for example, concrete M300 withstands up to 300 kg / cm2.

The solution class indicates a guaranteed strength of 95 cases out of 100. Range of indicators from 3.5 to 80.

Plan a specific type of mix based on the destination.

The table below shows the allowable brands and classes of concrete with strength indicators.

How to make a concrete solution?

You can prepare a mixture yourself in two ways:

- manual

- mechanical (using concrete mixer).

The first will, naturally, more laborious, but, with a minor amount of work, it is quite acceptable and economical.

Use concrete mixer with large volumes or increased requirements for the strength characteristics of the concrete mixture.

Preparatory work

Preliminary work is necessary independently of the further method of preparing the solution. They are in the preparation of materials.

Sequencing:

- Suck sand.

- Rinse crushed stone.

- Dry both substances.

Concrete standards

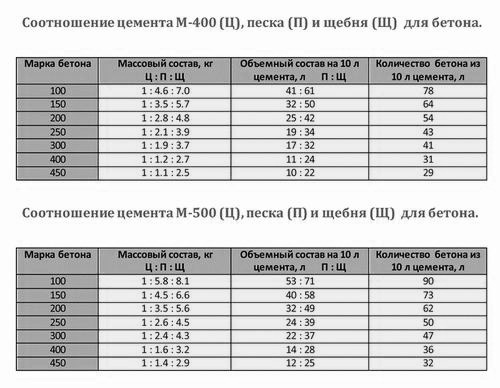

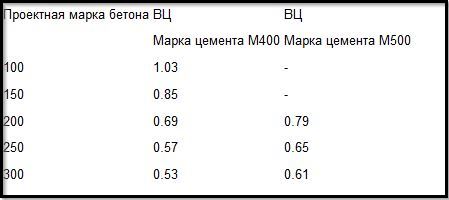

In order to get a concrete of a certain brand and strength, comply with the preparation formulation.

Choose the most convenient principle of the calculation of the consumption of components:

- kilograms

- litres

- percentage

- number of parts.

Carefully consider below the tables in which the various possible options for the preparation of concrete are indicated.

Important! Note that in each individual case, deviations from the norm, which are regulated by the quality of materials.

Conditions for cooking

With independent preparation of concrete, be sure to observe not only the technical moments of the process, but also the conditions in which the solution is produced:

- air temperature 15-20.

- humidity level within 90%.

Important! If the fill is carried out under conditions of severe dryness or low temperatures, use special additives that regulate the process of frozen, thermal insulation materials and additional irrigation.

Manual solution manufacturing method

The order of cooking concrete:

- Prepare a container for mixing or special platform (shield) with a solid smooth surface.

- Prepare shovels, buckets, watering can.

- Measure all substances according to the recipe.

Important! All measurements are performed by one bucket to save the accuracy of the parameters.

- Mix sand and crushed stone.

- Make in the middle in the resulting hill dry mix depression.

- Pour cement into recess.

- Mix thoroughly to a homogeneous mass.

- Make in the middle deepening.

- Pour a small amount of water by water drill.

- Push up the mixture from the sides to the full absorption.

- Mix the shovels with chopping movements.

- Repeat the procedure for adding water and mixing before creating a homogeneous mass of the desired consistency.

Important! Ready concrete is a thick, but fluid mass. With an internal screed, the use of a liquid solution is permissible, but its strength will be lower. Hard concrete will require a thorough rambling.

Capture concrete mechanically

Types of concrete mixers

There are two types of concrete mixers:

- gravitational

- forced action.

In the first case, the mixing occurs due to the rotation of the drum with fixed blades installed inside it. In the second - mixing is performed by blades rotating in a certain mode with fixed Badier.

Each of the species has its advantages:

- compactness, light weight, low cost is inherent in gravitational apparatus

- higher mixing quality will be obtained when using a forced type concrete mixer.

Important! For independent preparation of concrete at home, a fairly gravitational apparatus is quite enough. Note that with a very large amount of work, you will most likely need not one, but 2-3 concrete mixers.

How to cook high-quality concrete?

In the process of preparing concrete in a concrete mixer, an important factor is the component load sequence. From how correctly the technology is chosen, the quality of the prepared mixture directly depends.

There are many opinions on this. Below is the technology of a more rational approach to the fulfillment of this work.

Cooking technology

- Install the concrete mixer on a flat surface.

- If necessary, create additional substrates to increase the stability of the apparatus.

- Lubricate the blades and walls of the concrete mixture with a mixture of water, cement and aggregate of small fractions.

Important! This action will prevent the solution of the solution.

- Turn on the device.

- Fill half of the prepared water.

- Put the crushed stone to the drum - half of the total.

- Lose 2-3 minutes of mixing.

- Add cement.

Important! When applying cement after rubble, larger fractions of the filler prevent the cement sticking on the walls and the blades. Plus rubble helps to split the formed lumps.

- Look out some time mixing (about 3-5 minutes).

- Add sand.

- Leave for mixing for 2-3 minutes.

- Add the remaining crushed stone.

- In the process of mixing, pour the remaining part of the water, bringing the solution to the desired consistency.

Important! After adding all components, no rotation is recommended for more than 2-3 minutes. This can lead to loss of plasticity, bundle and evaporation of water.

- Turn off the unit.

Important! During the fulfillment of all work, follow safety techniques:

-

do not shove your arms and shovel inside when rotating

-

Work in protective gloves

-

Do not lean close to the drum.

-

- Pour a small piece of the cooked mixture into a wheelbarrow.

- Check the quality of concrete.

Important! One of the ways to verify the quality of the solution is to make several ribs shovel. If the concrete of the desired consistency is - they will retain the form. But, while the mixture should be fluid.

- Unload into the container if the desired plasticity is achieved.

- Put the mixture back and mix again if the concrete is not ready, then unload into the container.

- Wash the concrete mixer.

Important! Consider the allowable amount to mix the specific apparatus you have chosen. The main criterion is a major aggregate, which, with an excessive amount, interferes from making a full-fledged proper level. For example, for a concrete mixer with a capacity of 132l, the limit number of rubble for one preparation is 4 buckets.

Video preparation of concrete mix

Conclusion

You can use the finished concrete mixture throughout the limited period, so count your actions and time to avoid long-term storage of the mass and premature drying of the solution. This will lead to a decrease in the original quality, and accordingly affect the strength during operation.