Cement mortar - a mixture created on the basis of cement. This mineral substance has high durability, plasticity and versatility, so won great popularity in construction.

In this article, we will look at how to make cement yourself using special technology.

Content

Application of cement composition:

- used when pouring floor screed;

- in the production of concrete and w / b blocks;

- in the production of paving slabs;

- during plastering;

- for the construction of brick walls as a solution, etc.

The strength characteristics of the cement mixture are fully dependent on the technology of its manufacture and quality of components. Preparation of cement is a responsible process, to violate which should not, otherwise it can lead to the destruction of the structure. It is very important to observe a certain dosage of components.

When building residential buildings, a variety of piece elements are used: panels, bricks or blocks. And in order for the future design to have high strength, separate building materials should be associated into a single monolithic product. When creating construction solutions of high strength, special composition is used - Portland cement.

Cement do it yourself

Cement and preparation of the solution

The main components of the building lineup are:

- aggregate (sand);

- water;

- binding substance (plaster, lime, cement).

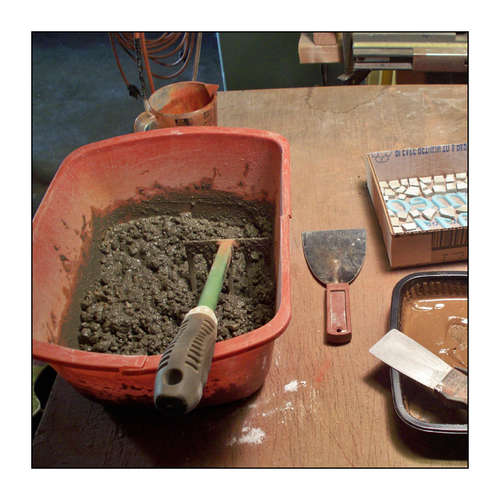

Preparation of cement:

- initially, you need to prepare a dry composition of sand (lime) and cement;

- sand for cement is taken in the ratio of 2-5 parts;

- cement and limestrokes are prepared from lime, cement and sand in a 2: 1: 6 ratio;

- if necessary, the amount of sand can be increased to 9 parts.

The use of cement-sand mixtures:

- for plastering internal and external walls;

- for floors of floors;

- during the construction of walls;

- when bookmarking the foundation;

- indoors with high humidity.

The use of cement-limestone mixtures:

- for plastering;

- for work inside the building.

Cement consumption for the preparation of the solution:

- for plastering, the ratio of cement and sand is used - 6: 1;

- with brickwork - 3: 1;

- bookmark the foundation - 1: 1 or 2: 1, etc.

Recommendations:

- when sifting sand sieve, you need to choose a certain cell size;

- or the river sand is better not to use;

- pay attention to the homogeneity of the solution;

- strictly follow the technological process;

- no need to take icy water;

- water, sand and cement should be added in small portions;

- the composition must be mixed thoroughly;

- the solution should not be spread and be overly dry;

- the use of the composition is needed for half an hour;

- store dry cement should be kept at low humidity and in a warm place;

- remember that masonry and plaster imply special solidification conditions.

The process of preparation of cement lime mortar:

- sand sieves with sieve with 3x3 cm cells;

- if it is used not to hate lime, it should be paid off (we fall asleep it into non-plastic barrel, pour water, closed the lid and leave for a day);

- we take cement 400 brand;

- the ratio of 1: 4: 1 (lime milk, sand, cement);

- then, in the tank, smear the sand, cement, sand, cement and mix;

- add lime milk, which is suitable through the gauze;

- next to the desired thickness, we pour water.

Recommendations:

- to determine the quality of the mixture, lower the shovel into it;

- if there is a lot of solution on it, then add the sand;

- if nothing has been naliply, add lime and cement;

- if the solution was nalyuple, then it is ready to use;

- the finished composition should be used in 2-3 hours.

Preparation of cement sandy solutions

Recommendations:

- for floors of floors, the ratio of sand and cement is normalized from 2: 1 to 6: 1;

- classic version 3: 1;

Cement-sandy screed solution:

- initially, mix dry components;

- then gradually pour water to the formation of sour cream;

- give a mixture to stand for 15 minutes;

- next, mix it.

If it is necessary to make plastered walls, then a lime solution is added to the cement-sandy mixture. The optimal ratio of lime mortar, sand and cement 2: 5: 1.

Brands of cement solutions

All grades of sand-cement formulations are applied in their own intended purpose, while each determines the strength and scope of the use of building materials.

The mixtures brand are created by a special recipe and can be:

- simple (with the use of exclusively main components: water, sand and cement);

- complex (using plasticizers, which improve the characteristics of the mixture).

Today, the following brands are available:

- M200;

- M150;

- M100;

- M50;

- M10;

- M4 and others.

At the same time, each of these species of decorative and building cement-sand solutions is used for certain purposes and has its own acid resistance, heat resistance, frost resistance, viscosity and water consumption. All components and parameters of solutions are regulated by SP 82-101-98.

By the main purpose of the brand are divided into:

- plaster;

- masonry;

- facing.

By density:

- heavy;

- lungs;

- middle density.

Using brands:

- for screeds, M200 and M150 brands are used;

- to fill the seams in coatings from piece elements and for interlayers - M400; M300, M150;

- for coatings - M300, M200, etc.

How to make the cement with your own hands video:

An article about anything. How to prepare buns from buns.

And how to make cement without cement?