The terrace at the cottage is the place where the whole family is going to warm summer evenings. For its construction, you can use various materials. Our article we will talk about how to make a wooden terrace.

Content

Why better choose a tree for the terrace

It is clear that the brick or concrete building is a more solid construction. But for such buildings, a massive foundation is assumed. If we use wood, then over time the terrace can be increased in length or width. And the construction can be made any form.

In addition, a wooden terrace is characterized by:

- ecology;

- slight weight;

- excellent strength;

- resistance to mechanical stress and strong vibration;

- the presence of a comfortable temperature at any time of the year;

- lack of deformation seams.

The only nuance is mandatory wood treatment with special impregnations. Moreover, it is necessary to acquire only high-quality compositions, thanks to which there will be a fire safety and operational period of construction.

Location Building

In most cases, wooden terraces (in the photo) are an extension to the main building. For this reason, one of the main criteria for their placement is the ratio of the parties to light.

The terrace that will be used only in the summer period is better to arrange from the northern side. Throughout the day, the sun rays will not fall into the room. Moreover, if necessary, you can take the entire northern side of the house. This is usually done when there are no windows on this side.

If a terrace is erected without contact with the house, the best place is near the water bond (reservoir, stream, waterfall or conventional pool).

By drawing up a wooden terrace project, attention should be paid to the correct definition of its size. After all, the amount of material used and the total cost of installation work depends on this indicator.

The most common material is a timing segment 1 * 1 m or logs, which have a thickness from 1 to 1.2 m. The simplest solution is a square or rectangular extension to the house.

The construction technology of the terrace involves working on the device:

- foundation;

- wooden flooring (floor) and frames for walls;

- roofs;

- additional elements.

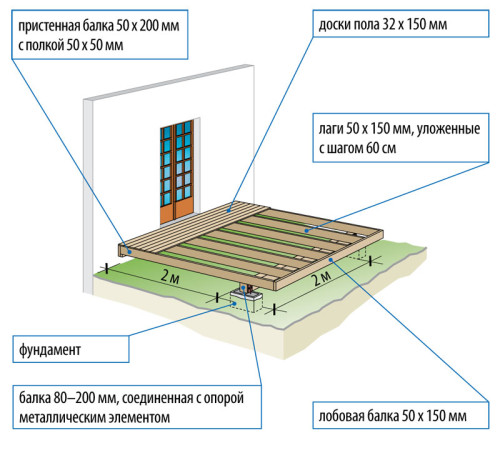

Creating a foundation for a wooden terrace

The manufacture of wooden terraces begins with the markup of the site under the foundation:

- armature (wooden pegs) is driven around the perimeter;

- between it stretches the cord;

- at the corners of the future foundation, the support elements are mounted;

- lags are stacked on the supports (with a slight bias for water flow);

- everything is exhibited in a single horizontal plane (for alignment under the support, the brick battle is placed);

- there is an alignment of the stretched cord with its subsequent fixation to the reinforcement (it is done on the upper side of the lag).

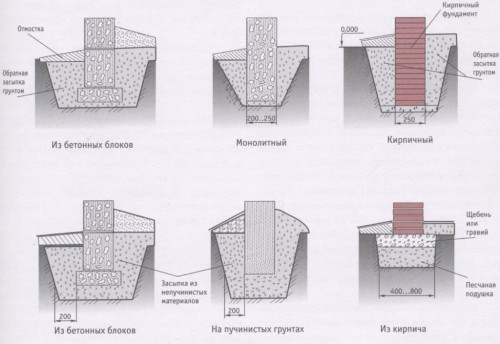

After conducting marking works, the foundation is embroidered:

- lags are cleaned;

- at the corners of the base, columns from cement are mounted (their height coincides with the size of the support elements);

- trench between the pillars made;

- concrete poured into it;

- paving borders are installed in concrete (enough half a height);

- all items are checked by the level of the correct horizontal location;

- concrete is frozen;

- all empties near the border fall asleep with sand.

If the area often go rains, then you should provide drainage. To do this, the inner part of the base is filled with rubble and pave pipes for water lead.

During the construction of a wooden terrace, which is adjacent to the house, necessarily carried out the binding of the two foundations. To this end, in the basement of the house drilled holes which are driven into the reinforcing bars.

Flooring and frame

To create the floor is carried out:

- installation and fixing the lag screws to the posts and curbs;

- marking Places boards connections;

- stacking boards with a locking mechanism by means of corners and lag;

- flooring planks;

- alignment electric jigsaw at parts of the floor;

- painting wooden flooring.

Strapping device for the lower corners of the steel used for connecting struts. Simultaneously with the tie-lag should create a special section of the grooves 50 * 50 * 50 mm, which are designed to studs. For fixing struts apply staples or nails cantrail elements to the posts and trusses - pins and staples.

Garden is better to use wood from hardwood. When laying the boards are left to vent gap, while they themselves are covered by boards antiseptic. If terraced decking will be applied, it is necessary to make a space from the wall in the 1-1.5 cm.

The end of all elements made of wood treated with a special composition. This reduces the moisture absorption of the particles from the air. The connections with the wall at home waterproofed.

Roofing

This step is the creation of a wooden terrace with his hands suggests:

- establishment run under the roof: the beam is attached to the wall by means of anchor bolts;

- fixing the ends of rafters to girder;

- lathing apparatus of boards, which is connected with the truss system;

- flooring over the roofing battens.

The possible use of slate, polycarbonate, metal, sheet metal roofing material. If the terrace adjacent to the house, between adjacent roofs should not be gaps.

When the construction only in the summer, you can make a removable roof. For this use an awning fabric, open in automatic or manual mode.

Construction of additional elements

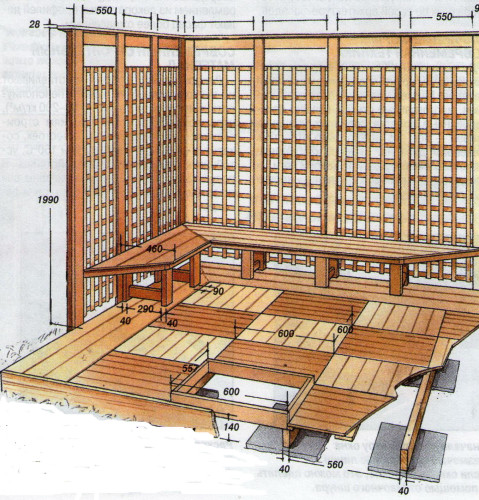

Inherent attributes of wooden terraces are the doors and walls. In some cases, the design is complemented by the window.

To install a window, you must build a windowsill. His mount is made at the height of 0.6-0.7 m. The covering of space between the floor and the sill paneling or boards used. Door installation is carried out in the most convenient part of the terrace.

For the manufacture of walls, we usually use rope boards or coniferous trees. As for the exterior decoration, there is a variety of options: the interior in a rustic, colonial or Japanese style. You can simply build a grille that grapes will cover (cultural or wild).

When using the terrace in the winter it must be insulated. For this, the penplex or foam-thickness is quite suitable for 4 cm thick, which can be mounted on the floor and walls. The joints of the heat-insulating material are sealed using a mounting foam, and the plates themselves are coated with a waterproofing film.

Features of the Wood Polycarbonate Wood Polycarbonate

Polycarbonate is one of the most sought-after materials. This is explained by its excellent features: refractory, flexibility, strength, simplicity of assembly, attractive appearance.

To bind the terrace with polycarbonate, it is necessary to make a frame from BRUSEV. The distance between the bars is 0.8-1 m, between the support pillars - 1-3 m.

In most cases, this material is used in the roof device:

- in the cellular panels are made openings at a distance of 0.3-0.4 m from each other;

- the sheets are fixed on the frame of self-drawing with special washers (self-tapping screws must be made of stainless steel);

- joints between the adjacent panels of polycarbonate (it is necessary to leave up to 5 mm) close up using decorative slats;

- the top end of the panel closes with a ribbon (so as not to moisture and garbage);

- in the lower part of the sheet, the ribbon with perforation (for the flow of condensate) is stacked.

Video about creating a wooden terrace: