In order to obtain designs from metal of the right form, with respect to the parameters specified in the project, the processing of all its items is pre-carried out. For this there are several ways that are most demanded from which - milling. The accuracy of the work performed directly depends on the correctly selected cutter - directly cutting material.

Content

Main Criteria Selection Cutters

To select the most appropriate type of tool, follow the following criteria:

- Scope of work and their diversity

- Quality of the required finish (primary or secondary processing)

- Metal quality (softness, thickness)

- Geometric surface shape (holes, grooves, flat stove)

- The specified size accuracy.

Important! When performing mass work on molding multiple surface types with different lines, pay attention to the sets. In this case, the price of metal cutters will be significantly lower, and a variety of configuration will help perform several types of work.

What to pay attention to the selection of mills on metal?

- Manufacturer. When choosing pay their attention to the brand, time-tested and users, in order to avoid the rapid breakdown, defective or malfunctioning sharpening parameter figured cutting on cutters. List of recommended manufacturers:

- The principle of operation of the mechanism. It is also important when choosing a cutting tool to take into account the quality of the machine: manual cutter for metal, semi-automatic or automatic device. To him by selecting suitable attachments.

- Compliance with internal attachment. In addition to the quality of working directly with the outer surface, it is important to match the internal bore and having veneer parts for a snug fit to the base of a rotational mechanism.

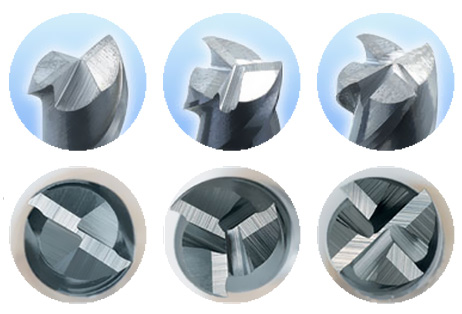

- The diameter and structure. cutters size affects the value and usability of the tool, so choose for themselves the most efficient combination. By type of cutter structure is divided into:

- Quality sharpening. Please note that the better sharpened instrument, the higher the quality of design of cut and less time spent on its implementation. Please note, some manufacturers create a unique sharpening that is both a disadvantage. This mill is difficult, and often impossible to recover on their own after it is worn. Interesting offer of some manufacturers - replaceable blades, which provide long-term use.

- The material of the cutting member. Separately, we note the importance of quality used tool material, regardless of the selected cutter design. Especially popular in this respect the use carbide cutters for metal due to its high rate-hot temperature.

The advantages of their use:

- external strength and necessary rigidity of the tool

- high-hot temperature, which prevents the rapid heating during operation

- inner core cooling equipment, through which is extended the possibility of continuous processing.

Important! Tungsten carbide cutters are ideal for hard-to-strength alloys:

Possible manifestations in the process of performing work that reduces its quality

In addition to the main selection criteria, keep in mind and some nuances that may occur during the processing process:

- vibration

- strong heating (up to the coating temperature), both the tool itself and the designated parts

- curling chip

- shrinkage material

- the appearance of growths when molding parts from plastic, soft metal.

Important! Take advantage of special attention to the specified conditions. All these manifestations significantly affect not only at the time of work, significantly braking the process, but also on the quality of the obtained part.

What works use cutters?

Based on the appropriate selection criteria indicated above, consider when purchasing the appropriate type of tool, focusing on the challenge of the work on milling:

- Chernovaya and decorative processing of planes

- Registration of shaped products

- Cutting

- Creating grooves and lesions

- Sleet holes

- Cutting teeth and threads.

Recommendations for choosing a cutter type under a certain type of work

To perform each type of work allocated in the classification above, several varieties are available. Check out the recommendations for the use of the most popular, in accordance with the specifics of the alleged work.

Blacks and decorative processing of planes

Depending on the type of tool itself for draft work, you choose:

- larger diameter of the working rod

- larger-size teeth and lesser frequency on the working surface

- fewer feathers, for example, for the terminal milling mill.

Important! All initial processing cutters are designed for rough finishes, creating outlines of the main geometric shape of the product. At the same time, a thicker layer of material is removed.

Decorative finish is performed by milling cutters of smaller diameter, length, teeth, lots of feathers. When performing finishing finishes, only a thin layer of material is removed.

Important! It is impossible to give clear recommendations for sizes, as they are selected for hidback, and for pure work, clearly under a certain task.

Technological novelty of some current manufacturers are universal cutters that can be performed at any stage.

Creating shaped products

To perform such works, special cutters of a suitable profile are used. The easiest option is to create an angle of a certain degree. For this, the angular cutters of the corresponding sharpening are used. Multiprofyl nozzles allow you to make the grooves of a complex structure, exactly the corresponding project.

Cutting

Details of cutting mills for metal have the shape of a flat circle with teeth along the edge, located in a certain order.

Depending on the intended works, pick up one of the species, given the frequency and size of the teeth:

- frequent

- middle

- large.

Also note when the cutter is selected on the metal metal and the thickness of the circle itself.

Registration of ledges and grooves

To process and maximally create simple and complex geometric shapes on the product use several types of cutters. The main criterion for choosing is the type of specified ledge:

- triangular

- rectangular

- trapezoidal.

Important! In this case, apply and round cutters for metal, and end, and end, and disc. The tool with round plates is especially interesting when creating a bulk form and a variety of alleged work.

The location of the ledge or groove also affects the choice of a certain cutter:

Important! For external recesses of different types and shape, end mills are perfectly suitable for metal. End allows you to perform work not only on the outer surface, but also to arrange deeper and internal grooves, ledges, various joints perpendicular planes. Multistage surfaces of structures are created using cylindrical milling mills.

Sleet holes

To cut through the holes of the desired depth or through, use end, straight edges or cutters cropped for metal.

The latter due to the cutting of the metal only on the edge of the opening is in high demand. To perform this work, pick up the parts corresponding to the diameter of the future holes.

Important! To facilitate the work, use the cutter for metal to drill, which allow you to purchase all the holes as quickly, accurately, clearly and without excessive vibration load.

Separately, we note another type, without which the adjustment of the inner surface of a variety of valves, created by a spherical form, is the cutter of the metal. Its application allows not only to adjust the geometric shape, but also to give the desired surface texture.

Cutting of teeth and threads

To work this type, prepare the cutters of a worm special coating profile or disc modular appropriate size.

Important! It is noteworthy that it is possible to obtain the desired thread, as a single tool (thanks to a specific sharpening, the hole is first drilled, then the thread is cut) and several specially selected (separately to create a hole, the second - for applying notches).

Conclusion

A distinctive feature of this tool for metalworking is a manifold of forms, types, sizes, profiles, destination. Therefore, before making the final selection of cutters, make sure that you have viewed all the available options for the categories of interest and chose the best.