The rise in energy prices makes think about using the sources of free electricity of many country house owners. In addition to savings, alternative sources are necessary in unstable power supply. Therefore, the following information is for those who are interested in how to make a wind power plant. This is the most affordable way to provide your dwelling with cheap energy.

Content

Tools and Maintenance Mounting Windmaster

Wind power station with their own hands is not a difficult thing. In order to start its installation, you need to stockpenter. It will take:

- The electric motor with a power supply is 260V and 5a of a direct current, equipped with a trimming sleeve of 150 mm. It allows you to generate a current by force 7a at wind speed close to 48 km / h. The size of this unit is relatively small, the cost is also. The windmill generator is any engine (for example, from a treadmill) capable of producing current more than 10a. In the absence of a sleeve - it can be replaced with a gross adapter of a suitable diameter.

- Materials for the manufacture of the carrier bar: a pipe with a length of 920 mm square cross-section with a side of 25 mm, a pipe (round pipe with a length of 150 mm with a diameter of 50 mm), a screw of 19 mm long.

- Bolts 8x19 mm (for engine).

- Diode bridge from 30 to 50a.

- PVC tube with a length of 280 mm with a diameter of 75 mm.

- For the manufacture of the shank, it is necessary to tin 300 × 300 mm.

- For the manufacture of blades, a pipe is 600 mm from PVC with a diameter of 200 mm (painted for protection against UV radiation), washers 6 mm, 6 × 20 mm bolts, tape and paper.

In the manufacture of some components, the mechanical connection of parts can be replaced with welding.

Requires tools:

- Electrode with a set of drills (5.5 - 7.5 mm);

- gas and adjustable keys;

- electrolovka with a pilot for metal;

- screwdriver;

- roulette, transport, circus, transport and marker;

- tap ¼ × 20.

Making blades

The wind power plants for the house work efficiently if their blades of the right form. You need to make nine blades (three sets). Phased on how to make a windmill.

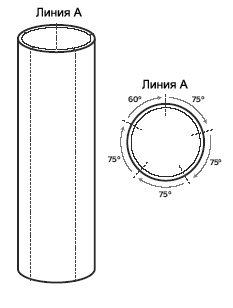

- PVC pipe Install the end to the plane together with a tightly pressed square tube. On the pipe from PVC along the contact line, a line should be carried out, denote by its letter A.

- Having postponing 1.5 cm from the edge of the pipe, put the labels at the ends of the line A.

- Three sheets of paper A4 paper glue length, after which they wrapping them the pipe and the marks take turns to apply paper to the pipe. At the same time, the short side of the roll of paper should lay down to the line and tightly, the long overlaps exactly at the places of the adhesion of one layer to another. Along the edge of the paper should be conducted from the ends of the pipe. Denote the lines formed by the letters in and C.

- The pipe orient so that its end, located near the line B, was at the top. At the point of intersection A and in, it is necessary to set marks along the line in with an interval of 145 mm in the direction of Left from A.

- Using a square tube, the specimens of opposite ends are connected.

- The electric bubble tube should be cut according to the marked lines. As a result, four bands of equal width (145 mm) and a narrow segment are formed.

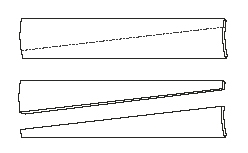

- All bands orient the concave part down, after which you need to put the label points on a narrow part of the bands, retreating 115 mm on the left and the same - on a wide part by retreating 30 mm in the same way. By connecting the points, we obtain the diagonal lines for which you need to cut plastic.

- The blades are put on a concave surface down and at a distance of 75 mm from their wide part make a mark. Other you need to put 25 mm at a distance of a straight edge. According to the line, connecting the point, cut part of the blade: it will not allow the wind to climb them with wind.

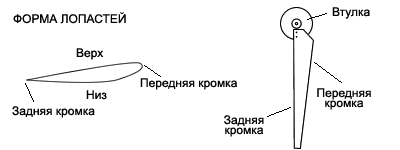

In order for the blades to be strengthened, they need to be treated with sandpaper and remove sharp faces and burrs. The front edge is spinning, and the rear is formed acute. This will reduce the noise and increase the efficiency of the entire system.

Production of other details and assembly

For the correct orientation of the horizontal wind generator, a shank is required. The dimensions of its values \u200b\u200bdo not have: sufficiently a piece of rigid tinsel size of 300 × 300 mm. The shank is mounted with self-draws to the square pipe, at the opposite end of which the engine is installed. The bushing with blades attached to it is attached to the motor shaft. If necessary - the engine housing should be closed by a protective sleeve made from PVC pipe with a diameter of 75 mm.

Homemade wind generators are different systems. The choice depends on the features of the terrain and strength of the wind. A wind generator with a vertical axis or horizontal can be used. Each of these systems has its advantages and disadvantages. The wind generator vertical is more efficient at low wind, but for areas located on the hill, it is recommended to use the horizontal type wind generator circuit.

How to make a wind generator: phased instructions for further action.

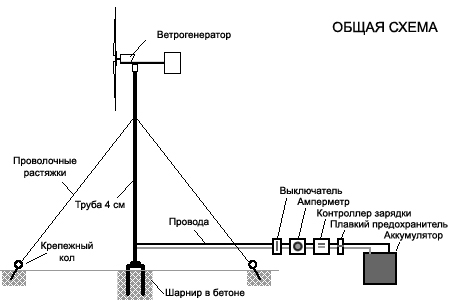

- After mounting the engine to a square tube with a bolts of 8 × 19 mm next to him, a diode is fixed. One of the engine conclusions (black wire) is connected to the plus contact of the diode. Red wire (second engine output) - to a negative contact.

- The blades to the sleeve are fixed with 6 × 20 mm bolts using washers. Tightening bolts should be tight.

- To the flange using the gas key, the nozzle is attached 50 mm.

- All metal parts need to be painted to protect against corrosion.

End of wind generator installation

To completely assemble the wind generator with your own hands, you need to install the mast on which the electrical cable attached to the engine is being laid. The mast is installed on stretch marks and should withstand the strong gusts of the wind. If necessary (if the windmill failed), it should be possible to lower it. Wind power stations are able to produce electricity for several decades.

There are other methods of manufacturing wind power plants capable of providing a housing with consumers with a capacity of up to 500 W. One of these ways is presented on video.