The drill is a cutting tool that serves as an addition to the instrument handle with an electric motor. They can only work in aggregate. Drills are often designed to drill holes of various diameters on the material of many densities. Nowadays, any professional builder does not represent its work without such an assistant. In domestic conditions, it is also often used, for example, in order to make repairs, hang a picture on a concrete wall or install furniture.

Content

Drills: Features

- There are many different types of cutting tools. Drills for metal different from that of the tree so that the former is present TCT, while the second has a unique sharpening trident.

- At first glance, it may seem that the drilling of the holes is a fairly simple process, however, it seems only until you start to do it with your own hands. After all, it is necessary to understand which metal drill to choose and how to use it based on the surface material for work.

- The novice builder when buying a drill is not easy to navigate among a large assortment of tool. Without the help of a specialist hard to decide and dwell on a suitable model.

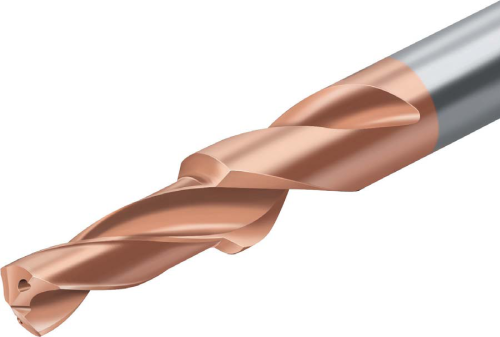

- The usual drill consists of three zones: cutting, calibrating and shank parts.

- In the first part there are edges that perform a cutting function. For this component there is a calibrating part on which there are grooves that ensure the decoration of chips. This zone is responsible for the quality and uniformity of the hole, and also sets the desired diameter size.

- At the end of the metal drill is a shank, which is attached to a tool or machine. This detail has several forms: conical, cylindrical or hexagon.

- The conical metal drill is inserted directly into the machine, and the cylindrical is in the cartridge of the tool.

Types of drill

We will describe in more detail all types of drills for metal and determine how to choose them under a certain job, as well as what should be care for them.

Spiral drills

This is the most common type of drill. It has a spiral form, so it is called. On the instrument there are two swirling longitudinal grooves with an angle of inclination from 10 ° C to 45 ° C, which are incremented during operation. The end of the drill is always sharp. This type is used both for manual drilling and to work on machines.

Metal conical drills

For a stationary machine or special drill, a metal drill with a conical shank is used. It is clamped in a special machine with a specific ending for clamping. Use this type of tool to drill large diameter holes. Such drills have five sizes.

Coroned metal drills

Such a drill will easily make a hole in a metal tube or a fairly thick sheet. It can make a hole of a rather large diameter and depth. It helps save energy due to the fact that only affects the outer edge of the future hole, due to which he reduces the wear of the electric motor and the drill itself. Such a tool does not require frequent sharpening and help when driving a drill with a smaller drill, which makes it possible to speed up the running time. Crowned drills can make holes from 5 mm.

Step metal drills

Such drills are also called conical. Step drills have a view of a cone on the form of the working part. This is a pretty new kind of building tool and users of ordinary drills do not yet understand what their advantage. Think about whether there will be a waste of money, the acquisition of this type of tool. After all, the price of such a type of metal drill significantly exceeds other traditional samples.

Advantages of stepped drills

- The edges located on the conical part of the drill have a high strength indicator due to which provide a large working resource.

- Resistant to overheating.

- The drill cone is designed in such a way that with each edge diameter becomes more and more, and it increases in the form of a New Year tree. The hole made in this way becomes universal, so you can make holes in various diameters, and this is saving not only tools, but also time on the selection of the tool.

- Step drills are used to drill on the material of various types: plastic, metal, plywood, tree and other surfaces.

- Another advantage of such drills is the drilling rate, as a result of which, even in a thin sheet metal, the edge quality is not reduced.

- During operation, there is no need to apply additional centering elements, which significantly speeds up the surface processing process.

- A special strength of the product gives abrasive spraying, so that there is no need to constantly sharpen the tool.

- During the treatment of surfaces, such drills does not arise from sowing and peeling the paint coating, and the holes are obtained smooth and beautiful.

Disadvantages of stepped drills

Metal cone drill users mark only 2 disadvantages - this is a small height of the edge, which provides a smaller depth of drilling, and the high price of this type of metal drill.

Level Drills with left-sided rotation

On sale this tool can be found very rarely, as their use is narrowly specialized. Apply them to drill "broken", "burnt" bolts or other fasteners.

Carbide Metal Drills

- The tool received such a name due to the equipment of the drill plate of solid alloys. They are used mainly to work with cast iron, as well as with non-metallic material, for example, marble, plastic, etc.

- Such drills are not popular in everyday life, they have a number of disadvantages, such as:

- large axial load;

- insufficient drill mount;

- the rate of drilling change;

- large width of chips, and, therefore, and the high probability that it will be stuck in the groove of the product;

- insufficient power and a small number of revolutions, the risk of vibration.

- They are not found on sale, but you can buy under the order.

High accuracy drills

These drills are buying those owners who are important high accuracy of the result. The degree of quality defines the type A1 or B1. The higher the accuracy, the topics of the drill will be much larger.

Drills for thread

The product is designed to create a thread on the ready-made hole. At the same time, choose the drill must be smaller by 1 mm. For example, if you need a hole thread in 5 mm, you should take a 4 mm drill.

Dimensions: Specificity Application

Metal drills are distinguished not only by its own characteristics of the structure, but also sizes, as well as diameter. Thus, the drills are divided into elongated, long and short.

Elongated drill

- The elongated metal drill is used in most cases to drill holes passing through, as well as in the items with a deep length.

- Use them when working with alloyed and unalloyed carbon steel, non-ferrous metal, cast iron and bronze.

- For the elongated drill, low performance is characteristic, but it has excellent resistance to breaks.

- When buying such a tool, pay attention to the product color, labeling, sharpening angle and material from which it is made. We will talk about these characteristics in more detail later.

- This design may have several types of tools: spiral drills, as well as tools with conical and cylindrical shanks.

Long drill

- Long metal drill has a number of valuable positive qualities:

- able to make a deep hole on hard surfaces;

- in such drills there is no beating;

- it serves long enough;

- does not overheat while working;

- you can use on the machine or install in a special drill cartridge.

- It should be understood that the longer the drill, the greater the diameter of the drill, because if it is, for example, a length of 200 mm, and in a diameter of 2 mm, then the product will simply break, not having time to start work.

- The diameter of long drills for metal is from 1 to 20 mm, while it can range from 19 to 205 mm.

Short drill

- Short drills for metal are more efficiently used for small neat holes.

- Work with them can be done on low revs.

- Such a tool is used mainly for handmade metal.

- Also, thanks to this plan, the drills can more clearly center the locations of the hole, if there is no initially suitable drill to work. The diameter of such drills is from 0.3 to 20 mm, the length varies from 20 to 131 mm.

Metal drills: how to choose the best

Choose the perfect drill for your needs is easy, you only need to follow the characteristics of the tool:

- colour;

- quality and appearance of the drill;

- fulfillment of product sharpening;

- diameter;

- manufacturer;

- the form.

Before you purchase a drill, you need to decide for what works it will be required, and what value you are counting on.

Metal Drill Color

The first criterion when choosing a metal drill is the appearance of the product, in particular, the color. According to it, they find out what material it is processed. The following color characteristics are distinguished: gray, black, faded golden and intense golden color.

Gray drill

- It suggests that the tool was additionally processed.

- It is the cheapest and most unreliable material, so it will last a short time, it will be good if you can finish at least one process of drilling.

- The only advantage is its low price, but it does not justify the funds in the purchase of such a tool.

Black color drills

- This color indicates that the drill was treated with overheated steam, as a result of which his service life is significantly extended.

- The cost of such a tool is a bit more expensive, but its acquisition is quite accessible.

Flusted golden color drills

Such a shade is obtained after vacation in the manufacturing process, for removing the voltage in the censum metal. Due to this processing, the strength of the metal increases and the service life of the drill is extended.

Intense golden color drills

- This is the most expensive type of product of all of the above, which is the only drawback in the product.

- Drills of such a shade are covered by the most strong material - titanium.

- The tool provides high wear resistance, reduces friction during operation, which facilitates the conditions for its operation.

- The most durable and reliable material with which it is pleasant to work.

Before buying, decide on the intensity and duration of work with the tool. If you are a builder and there is a need to deal every day with the drilling of the holes, then the best option for the purchase will be drilled intensive golden color. Remember that saving on the acquisition of high-quality drill, you risk losing more time to work and inevitably quickly come across the need to buy a new tool through a short period of time. For household conditions, cheaper options are suitable, black drills or flexo-golden.

Marking drills

It is important to pay attention to the labeling of the drill, which indicates the size of the product and the type of metal, from which they are made. The main designations include:

- letter P, denotes that the drill is made of high-speed steel;

- the alphanumeric Latin designations speak about the alloy material and its number in the product. For example, M2-2 - parts of molybdenum are in the composition of the drill, and, accordingly, K3-3 - part of cobalt;

- imported manufacturers have the HSS Metal Marking Drills, and in addition to such an abbreviation, the material alloy also indicates and for what processing they are intended, for example, HSS-G TIN - it suggests that in the manufacture of titanium-aluminum-nitride spraying, especially Sustainable corrosion and provides a long service life.

The HSS metal drill kit is, perhaps, a dream for every wizard working daily with a tool in the professional sphere.

Metal Drill Manufacturers

Thanks to the experience and numerous practical reviews of buyers, several leading firms for the production of metal drills can be distinguished.

- Domestic manufacturers. If you saw the SSR sign on the marking, buy this tool without thinking, the drills of the old hardening are very durable and durable.

- Bosh Metal Drills have taken a worthy place in our construction market. This firm develops a large number of different high quality tools.

- Ruko has gained great popularity with its pricing policies and relatively good performance.

- Haisser production. Specialists consider the drills of such a firm with the most powerful and most elite, they are used both in production objectives and in domestic ones.

Store drills in special boxes that come with a tool, each in its place. The tool is not necessary to wash, it is better to just go through the drill with a rigid brush or tassel to remove chips or dust formed during operation. Observe safety equipment while working, wear glasses and gloves.

"... At the same time, you need to choose a smaller size by 1 mm. For example, if you need a hole thread in 5 mm, you should take a drill on 4 mm ... "

This information is not very accurate, the drill is taken by the diameter of the "thread diameter minus step". This is if approximately. And if it is necessary to accurately, GOSTS are used.