Despite the diversity of modern materials, wood remains popular among our compatriots. But there is one negative nuance: wooden coating can be destroyed due to a fire. For this reason, it is necessary to process wooden structures with flame retardant composition (it is also called antipiren).

Content

Classification of flames

The principle of operation of flame retardant materials is based on physicochemical processes that occur with the components belonging to the flame retardant. The main components of fireproof compositions are:

- low-melting substances (salt solutions of borne, phosphoric or silicon acids);

- substances that secrete gas (ammonia or sulfur gas).

When heating low-melting substances, a film appears, due to which oxygen can not get on the surface of the wooden coating. As a result of this process, an increase in wood fire. This improves the fire resistance of the material.

Due to the use of gas producing substances, the combustion process itself is depressed. Non-flammable gas protects wood from ignition by removing oxygen from the surface.

Antipirens are divided into:

- coatings;

- impregnations.

Fire retardant coatings have a significant drawback. They hide a textural tree drawing. What leads to a worsening of the appearance of wood. For this reason, the coating is better to use for the processing of hard-to-reach structural elements.

More advisable to take advantage of fire impregnations that happen:

- organic;

- water soluble.

Organic products suggest the use of solvents that are fairly flammable enough. It is unacceptable for wood. The most optimal option is the use of water-based impregnations that happen:

- chalked;

- laborious;

- unqualified.

Processing impregnates are subject to structures that are exposed to a wet environment in a minimum. Therefore, most often use the lighted compositions.

Selection of material

Any fire fighting must have a corresponding certificate and imprisonment of the sanitary and epidemiological service. If there is no permissive documentation, the flame retardant composition does not meet the generally accepted standards and requirements.

The most famous flame retardants for wood are:

- "Antipiren PP";

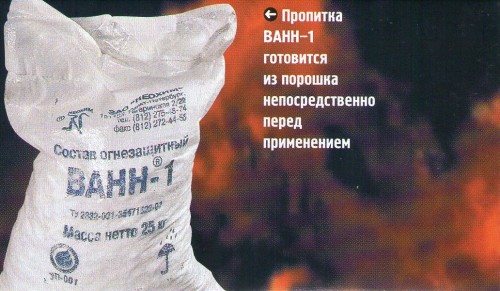

- "Baths-1";

- "Old Elm".

Formulations are available in powder form and dissolved in water. When working with them, elementary safety rules should be followed.

Treatment of wood impregnation

Depending on the degree of treatment, impregnating materials are two species:

- with superficial penetration;

- with deep penetration.

Surface flame retardant composition is distinguished by a low cost. The main component of impregnation is substances that prevent the process of burning the tree. In connection with the shallow penetration of impregnation, the protective characteristics of the wood are not very high. The application of the flame retardant can be carried out using a conventional brush or roller.

The treatment of a wooden surface of deep colorless impregnation is made using an autoclave or a special container in which the timber is soaked. After drying, wood is consumed for its intended purpose.

Another option of applying deep anti-fire impregnation is a vacuum technology under pressure up to 8 atm. and preheating to + 60ºС.

Regardless of the method of applying impregnation, the maximum efficiency of its use is achieved only if all the instructions prescribed by the manufacturer of products are reached.

When applied, impregnation should also be considered:

- season;

- the probability of impact of atmospheric precipitation.

If open areas or a unheated roof are subjected to processing with flame retardant composition, winter impregnation is purchased.

The use of fire painting paints

The principle of these flame retardant compositions is to create a layer, due to which heating is prevented and wood ignition.

Fire retardant paints are divided into:

- swept;

- unappropriate.

Pumping compounds are characterized by the fact that when the temperature is raised, the coating with the release of inert gas and water occurs. This leads to an expansion of the protective layer (10-30 times).

Unchecked paint consists of anti-view fillers and liquid glass. Depending on the variety and manufacturer, the flame retardant composition can have resistance to the direct effect of fire for 90-120 minutes.

In addition to the protective function, the paint does not allow the rotting of the wooden coating. The application of the flame retardant composition for wood is carried out using a pulverizer or roller. The minimum frequency of surface treatment is 10 years.

When creating a fireproof coating, you can use fire-resistant varnish. Moreover, it is applied not only for carrying structures, but also on wooden floors, furniture, laminate and polyvinyl chloride coatings.

There are the following features of the application of the material:

- varnish can be produced on a painted surface (with the exception of water-dispersion compositions);

- the process is carried out at a temperature of more than + 5ºС;

- application of several layers of varnish occurs with a time interval of at least 12 hours;

- the frequency of wood coating varnish is 6-7 years old.

The only nuance that should be taken into account when purchasing paints and varnishes is their target destination. For outdoor work, only facade materials are suitable, which are characterized by increased wear resistance and flame retardant.

Alternative options

In addition to impregnations and paintwork products, it is possible to improve the fire prevention wood properties by using:

- materials with which a refractory lamp is created;

- other constructive solutions.

Among the flame retardant materials should be noted gypsumless sheets. Due to the non-combustible material, the influence of heat on the carrier structure is limited. But there is a condition - all profile items must be processed by a special solution. Most appropriately used only in cases where it is impossible to apply flame retardant.

The use of rolled firefare (foil insulation) is the best solution for fire protection woods in hard-to-reach places (attic floors, attic, other low-transmitted premises).

As a constructive solution, the creation of a refractory belt (and better than a few), which will become an obstacle to the spread of fire. Places are determined with the greatest probability of fire. After that, refractory belts are created near them. In some cases, it is better to use a plastering mixture with a vermiculite or additionally build a reinforced brick frame.

Conclusion

Check the quality of wood processing by:

- visual inspection of the design;

- selective integrity examination and thickness of a layer of several sites.

Checking with fire is made using PNP-1 sensors. According to the results of research, acts are drawn up, which allow the operation of the object.

To check the quality of the flame retardant layer can be independently. For this:

- from the processed section, the sample is cut with a thickness of up to 1 mm;

- with the help of a lighter, a sample is ignited from the side where the flame has been applied;

- the billet should not support combustion or smoldering;

- after 20-30 seconds, the surface of the sample turns and coats (without flame appearance).

For comparison, you can take a piece of wood, which is not processed by flame retardant. When you turn on the lighter after 4-5 seconds, the blank will begin to burn.

Naturally, the combustion process directly depends on the type of wood. For example, oak sinters are difficult to set fire and without impregnation. For this reason, all checks are carried out on the basis of pine wood, which is easily flammable.

Video on the processing of a wooden structure with flame retardant composition: