Puzzle plates produce many manufacturers, including very well-known, but the products of the company Knauff are the most optimal option. Why? After reading the article posted below, you yourself make sure.

Content

What is a Knauf stove

The monolithic block of a rectangular shape with a size of 667x500x80 mm with a zip-groove type lock made of construction gypsum with the addition of binding components, and there is a Puzzle plate KNAUF. Used for mounting internal partitions, but sometimes used even for cladding walls of houses.

Advantages of Puzzle Plates Knauf

The use of these products reduces both the cost and complexity of laying partitions. Specific example: One PGP replaces 20 standard red bricks with a size of 25x12x6.5 cm or 14 pcs. Silicate half-and-and-half bricks 25x12x13.8 cm. In addition, gypsum puzzle plates KNAUF provide the same heat insulation as a wall of concrete 40 cm thick. The following facts are indicated about the economic benefit of material:

- installation is performed easily by gluing (dry construction);

- plastering are excluded. The front surface of the plates is distinguished by high quality. All that is required is to close the seams and stalind;

- when installing there is no need for special equipment;

- nails are easily clogged in the stove, they can be plane, saw, milling, therefore, the issue with electrical wiring and gasket pipelines in partitions is easily solved;

- the wall immediately after installation is ready to paint, cladding with tiles or pasting with wallpaper;

- pGP partition occupies a smaller area than brick;

- when the opening device from 0.7 to 0.9 m, it is not necessary to strengthen the top with the jumper beam;

- kNAUF puzzle plates having a sound insulation coefficient is 41 dB, perfectly reflect noise waves, are a dielectric;

- the acidity of the material is the same as the skin of a person, there is no smell;

- the material is suitable for erection of both single and double partitions with 4 cm by air interval, depending on the requirements for noiseing;

- plates are mounted with high accuracy and firmly connected together;

- the inner walls of plaster CNAUF are kept without additional strengthening the weight of shelves, kitchen cabinets, plumbing devices, etc.

The benefits of material include such its qualities:

- fire resistance;

- environmental friendliness;

- parry permeability.

Types of Puzzle Slabs Knauff

Distinguish puzzle plates:

- ordinary;

- moisture-resistant.

The first is used in dry rooms, and the second there, where moisture by definition SNIP II-3-79 is high.

Puzzle plates Knauf moisture resistant

Gypsum have the following characteristics:

- dimensions - 66.7x50x8 cm;

- mass - 28 kg;

- water absorption indicator - 5%;

- capacity per 1 square. M - 3 pcs.

Due to the presence in its composition special hydrophobic additives, Puzzle plates KNAUF Moisture-resistant perform the following functions:

- support the optimal level of humidity in the room, absorbing the excess moisture;

- select moisture when the air is very dry.

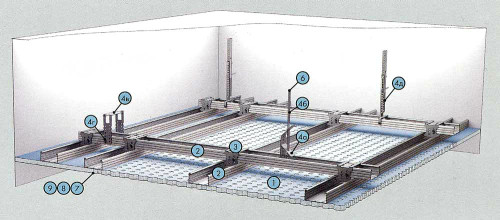

Installation of Puzzle Gypsum Plates Knauf

Puzzle plaster plates Knauf as far as easy to install, that even a non-specialist in a construction business will be able to build a septum at home. The question is only in time spent. For a professional, for example, nothing worth putting 20 square meters during the working day. m wall.

Before starting work, it is important to determine the requirements for sound insulation. From this depends on the method of adjacent partition to the designs in contact with it. If there are no specific conditions, the partition can be rigidly connected. In the case of increased requirements, an elastic adjoination is performed to sound insulation.

The installation process consists of the following steps:

- Preparation consisting in the selection of the necessary tool, removal of dust and garbage from the floor, walls and ceiling.

- Marking. On the floor draw the projection of the partition.

- Transferring the projection markup on the ceiling and walls using a plumb for strict compliance with verticality. Here I also celebrate the location of the openings.

- Horizontal inspection. If there are deviations, align.

- Laying of waterproofing strips. A film width is 2 times more than the thickness of the design.

- Preparation of the solution. Dry putty pour into the container filled with water, withstand about 25 minutes, mix. As a result, a mixture should be obtained, a consistency resembling a thick sour cream.

- Applying a solution. The prepared mixture is applied on the surface that will be in contact with the erected design - floor, walls, ceiling.

- Sticking the cork elastic gasket around the perimeter to the wet solution in a strictly horizontal position. This work is performed only when the elastic fastening method is selected in order to enhance sound insulation. Otherwise, a layer of plaster mortar is sufficient between puzzle plates and enclosing structures as a fastener.

- Installing beacon rails along walls for more convenient installation.

- Installation of the first row of plates. In the case of elastic mounting, it is started 0.5 hours after installation of the gasket. Plate's grooves can be directed both up and down. The first option is considered to be more successful from the point of view of the best distribution of putty in the puzzle castle. There is one nuance - in the first row from all plates the comb is removed. We apply the mounting glue to the upper and side sides of the plate and proceed to work. Laying tiles is accompanied by the control horizontally and vertically with the help of rules and levels.

- Further installation. When laying 2 rows and subsequent first apply a plaster solution in the end grooves and in the groove, if at the top, or on the crest of the top of the plate. The glue composition is better not to save. An indicator that it was applied in sufficient quantity is the leaking of glue from the joints between the plates after their connection. Next, we take the rubber hammer and seminding all the plates. Drinks immediately remove, and the seam equal. Watch that both vertically and horizontally, the thickness of the adhesive seam did not exceed 0.2 cm and conduct constant control using the rule, plumb and the construction level.

- Installation of the last row. The plates here are stacked in a horizontal position on the line is longer with a slope. A gap of 10-20 mm should remain between the overlapping and partition, to be filling with putty.

Important:

- when laying the PGP, as well as when performing masonry from a brick, mandatory is the disintegration of end seams vertically, i.e. The middle of the slab of each subsequent row overlaps the joints of the plates in the lower row;

- if the partition is high, then every 4-5 rows should be waited until the mounting glue is grabbing.

Insulation Knauf Thermo Plate

In addition to PGP, Knauf Thermo Plates, which are thermal insulation of fiberglass. From these plates, the thermal insulation layer is mounted during the device:

- scanty roofs;

- floors;

- overlaps, both attic and multi-storey;

- external walls and partitions separating rooms with large temperature dispersion.

Types of thermo plates Knauf

The company produces 2 types of thermo plates:

- Knauf Insulation - They are used by professionals.

- HeatKnauf - performed by technology 3 in 1, and are used in private house-building, produced in different modifications:

- Teploknauf (KNAUF) "Cottage" is a plate size of 1230x610 mm or a roll material with a thickness of 50 mm;

- "Cottage +" - characteristics are the same, but 100 mm thickness is not available in rolls;

- HeatKnauf House - made by the innovative technology "3D-elasticity", thickness 50 mm;

- Heat Knauf House + - thickness 100 mm, standal plate dimensions - 1230x610 mm;

- Heat Knauf Cottage - Releases only in rolls.

The advantages of thermo plate Knauf

Releases Knauf Termo Plates, having significant advantages over similar products of competitors:

- in the manufacture of ECOSE Technology technology, therefore, the material does not represent health hazards;

- possess high sound-absorbing properties;

- non-combustible;

- simple in installation, elastic and flexible, and therefore practically usable;

- have a small weight and well retain the form;

- vapor permeable;

- there are no smell, do not irritate the skin.

Knauf acoustics

Application of acoustic plates

In addition, Knauff slabs are in demand in such places:

- trading halls;

- offices;

- waiting halls;

- lobby and corridors.

These plates are also facing technical premises, including with aggressive environments:

- machine branches;

- ventilation chambers;

- pumping;

- boiler.

Specifications

| The size | 1,188x1,1998 M. |

| Perforation | 6,2-23% |

| Sound absorption coefficient | 0,6-0, (m) |

| Burning group | G1. |