One of the main issues that you have to solve in the Global Repair Process - replacement of the old floor covering on a new one, which is more modern: parquet, laminated, etc., as well as the creation of its quality noise insulation. The last improvement is necessary because the space of the room is filled with various stimuli in the form of sounds that interfere calmly relax. This constantly incorrect sound impact sufficiently negatively affects human health and does not allow to restore the strength.

Content

The main goal of noise insulation in the floor of the floor is to reduce the level of penetrating sound, which is formed by impact, friction or contact with any object. This problem can be eliminated using elastic building materials as an outdoor coating, for example, cork, carpet or linoleum. However, this case will not end, because it will be necessary to take care of other means of isolation.

How to create noise insulation

The insulation of the floor in the apartment is created using eco-friendly, practical and functional construction materials that have not very much thick, which allows you to put them under parquet, laminate or tile, while the space area is practically not affected.

Before beding such a soundproofing substrate, the optimal floor design should be ensured. This is necessary because in its destination it does not serve to align it. If you neglect the styling of the substrate, the floor will become a murmur, starts to knock and even trust with small grains.

After the screed is made, you can start the installation of noise insulation. Today, the most popular material is a foamed substrate. In addition to the fact that it has an acceptable cost and is considered a wonderful soundproofer, it also has insulating properties. However, with a constant load and uneven field, its surface can be used, which will damage the castle compounds of the laminated coating.

Also, the noise insulation of the floor can be equipped with a cork substrate, which consists of a natural crushed plug. This material is considered the most appropriate because it has an increased degree of sound absorption and is heat-conducting. In this case, the cork coating is quite firmly and steadily for deformation.

Noise insulation floor in the apartment, materials

In some types of the most functional premises, effectively create noise insulation using different types of insulation:

- polyenopolster;

- perlite;

- ceramzit;

- minvata.

These materials are stacked around the perimeter of the compound of walls and gender. In addition, this method will ensure excellent insulation, the room will additionally receive a warm coating.

Modern soundproofing materials:

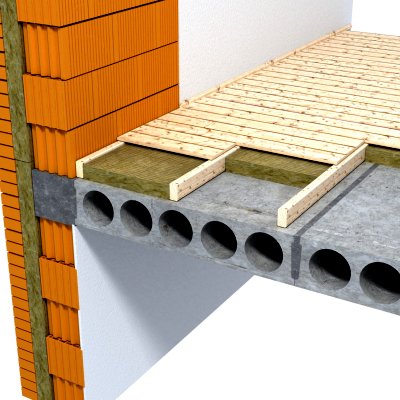

1. Eau return (sufficiently light noise-absorbing plates made from minvati based on fiberglass thickness 5-10 cm. Used when creating floor on lags).

2. Vibrastek-V300 (elastic rolled building materials 4 mm thick, designed to isolation from shock noise. It is used as a substrate and base for a floating type of screed).

3. Noise (elastic building materials, having a 2-cm plates with a thickness, intended for insulation from shock noise. It is used as a base for floating type of screed).

4. Shumane (elastic rolled material having 3 cm thick for insulation from shock noise. It is used as a base for a floating type of screed).

5. The underground plate of isoplat (made of coniferous chopped wood with a thickness of 0.7 and 0.5 cm. It is used for flooring floating type floor with a laminate coating or a parquet coating).

6. Isoplat softboard (fiberboard soft stove, having a 2.5 cm thick. Can be mounted under a concrete tie).

7. Texound (soundproofing heavy membrane, made on the basis of an aragonite mineral and having a thickness of 3.7 mm).

Noise insulation of the floor in the apartment with your own hands

As noted above, the most optimal option for sound insulation of the floor covering is a cork floating floor system. This type of flooring is a sand-cement screed, separated from the base and walls of vibration-sensing elastic building materials. This design is an elastic, remarkably absorbing vibration and not transmitting sound to the room, located below.

The role of the churring and noise insulating floating floor material can be performed:

- polymer foamed building materials;

- basalt wool;

- glass gaming;

- equata, etc.

Sequence of work:

- cleansing and leveling of the base, elimination of recesses;

- if minvat is used, steamproofing, whose joints are sized;

- then the installation of vertical elements, which separate the elastic layer;

- next, the flooring of the separation horizontal layer is made, which is stacked throughout the surface with small gaps;

- all pipes passing through the overlap must be wrapped with elastic material;

- on the damping layer laying the polyethylene film;

- we create a pouring of a sandy-cement screed using reinforcement and lighthouses;

- we produce styling the finish coating with certain gaps;

- fix the plinth either to the floor or to the wall.

When using this classical system of noise insulation, it is possible to install heating elements - a warm floor.

However, in addition to this option, there are technology of floating "dry" screed and precast coverage. Its main difference is that during installation, instead of cement-sand composition, gypsum-fiber plates are used, which are styled in 2 layers with overlap of the joints and sizing layers of specially intended glue.

Precast coatings for gender, which can be shared over the floating system:

- punching boards;

- prefabricated parquet;

- laminated coating, etc.

These outdoor building materials are stacked on an even base over the lining elastic material, which most often serves foam polyethylene.

Advantages of floating gender:

- is a reliable and durable system;

- does not assume the presence of special skills;

- uniformly distributed load on the floor;

- the presence of a gasket layer with a small indicator of thermal conductivity;

- lack of a mechanical method of fixation;

- increased sound insulation of the room.

Wooden floor insulation in the apartment

There are 2 wooden floor insulation methods:

- soundproofing of finished floor;

- noise insulation overlaps.

In both cases, the floating gender improvement is ideal.

Soundproofing overlaps:

- first you need to nail the bars to the beams for which the rolled noise insulating building material with an occasion at the wall;

- then the floorboard is fixed to the bars;

- plinths are fixed to the floor.

For noise insulation of the finished floor you need:

- single a soundproofing building material at him with a wall at the walls;

- welcome lags and nail the floorboards to them.

Floor insulation on lags

Progress:

- the floor is covered with soundproofing thin material, and lags are mounted;

- lagges made of timber are installed so that a 2 cm gap remains between the wall and the timber;

- this gap is filled with noise insulating soft building materials;

- there are soundproofing plates between lags with a thickness of at least 5 cm;

- then the base is poured with a screed of concrete or plywood sheets are styled (you can GMPs);

- next, the floor covering is laid.

Insulation floor under the tie

Consider the option using Vibrastek, Shumastop and Shumanet.

Progress:

- Shumanet is sprinkled with a mustache, and the joints are sickling with scotch;

- the reinforced screed must be a thickness of about 60 mm;

- schumastop plates are mounted closely over the plates of the overlap, separating from the walls with ribbons of the plug-in building material;

- then they are covered with a polyethylene reinforced film that comes under the walls on the thickness of the screed;

- Vibrations are steeked on the basis of the jack;

- between the coating and walls are paved vibratek tapes;

- next, everything is covered with a polyethylene reinforced film that enters the walls.

Noise insulation floor under laminate

Consider an option using isoplast.

Progress:

- the plates are mounted directly on the screed and align small irregularities of the base;

- Isoplat stele at an angle of 45 ° in relation to the floor covering and fasten with the help of glue, which is applied with points;

- laminate is mounted directly on the plates.

Noise insulation floor under linoleum

Consider the option using Vibrastek material.

Progress:

- the cloth of this building material is sprinkled closely, and the seams are fixed by scotch;

- linoleum is stacked on top;

- the design is fixed by the plinths that are nailed to the floor.

Floor insulation in the apartment video: