The foundation on the screw piles is the best solution in the construction of buildings in the area with relief drops. About the nuances of his device and will be discussed in our article.

Content

Advantages and disadvantages of the pile foundation

The construction of the foundation on the screw piles is the priority necessity if available:

- moving unstable soils;

- too much water in the ground (swampy sites).

The main element of the base is the pile, which is capable of withstanding soil shifts and solid lateral loads. The pile consists of three main parts:

- screw blades screwed into the ground;

- steel column;

- podle.

The diameter of the piles ranges from 8 to 13 cm. But the quality of performance depends not on the size of piles, but on the type of screw blades. It is the presence of a steady screw that makes the prevalence as reliable as possible.

According to reviews, the foundation on screw piles can be used on any soils, with the exception of stony.

The advantages of the pile base include:

- lack of earthworks and special equipment;

- the inability to clearing the site or removal of the upper layer of the Earth;

- speed mounting (you can cope in 2-3 days);

- the ability to dismantle piles;

- construction reliability.

It should be noted that after the screw foundation, it is not necessary to take a break in the work (as it is done when creating concrete bases). And the pile base is destroyed much slower than the foundation from concrete.

It may seem that the cost of the foundation on the screw piles will be high enough. But if you compare all expenses on its construction with a tape fundament device, there will be significant savings.

Minuses of screw piles for foundation are:

- corrosion exposure;

- the impossibility of screwing near the already erected structures;

- the complexity of determining damage in a patch hidden underground;

- the option with the construction of the basement is excluded.

To eliminate such a lack of foundation on screw piles, as corrosion exposure, the metal should be treated with anti-corrosion coating before carrying out installation work. Only so you can avoid premature wear of piles.

The process of creating a pile foundation consists of such stages:

- settlement;

- marking of the site;

- minting piles;

- base strapping.

Calculation of the foundation under the foundation on screw piles

At the initial stage, you should get information about the plot. From the type of soil will depend on the carrying capacity of the structure.

If the foundation device will use standard piles with a diameter of 10 cm and the wall thickness of 0.4 cm with a screw blade with a diameter of 30 cm, then the bearing capacity of each pile will be:

- up to 4 tons - on alumina soil;

- up to 6 tons - on loose soils, where the clay content does not exceed 10%;

- up to 9 tons - on the sandy and soup soil.

When calculating the foundation, take into account:

- load on the ground;

- depth of groundwater;

- maximum atmospheric loads (wind, snow).

It should also be noted that:

- the standard pile length is 2.5 m;

- the minimum depth of screwing is 1.5 m;

- when freezing the soil at the high depth of piles, they drop by another 20-25 cm;

- when lifting the base, longer piles are purchased.

Marking of the area under the foundation on screw piles

After applying the scheme of the layout of piles on paper, go to its transfer to the terrain. The error should not be greater than 2 cm in both the steps between the adjacent pile and in the vertical plane. Otherwise, this can cause a skew of a home or reduce the bearing capacity.

Piles are arranged so that the load is distributed evenly. To do this, take advantage of the building of the building. The house is conditionally divided into rectangles. Knocks or other identification items are driven by pegs or other identification items.

The amount and scheme for placing piles are determined based on the load. The distance between them is within 1.5-3 m. Piles are necessarily mounted:

- at the corners of future rooms;

- in the central part of the beams;

- under heavy equipment (for example, a gas boiler).

Miscarding piles

The structure of the foundation on screw piles includes:

- drilling holes to a depth of 0.6-0.7 m in places where the pegs are drunk (it is natural that the pile diameter should be less than the pile diameter);

- applying anticorrosion material on pipes;

- installation and screwing of piles in the hole (preferably below the level of ground freezing);

- cutting the top of the piles in a single horizontal plane;

- filling of pipes with concrete solution;

- welding of ads with a minimum thickness of 1 cm;

- processing of seams.

Start the process should be taken from the installation of angular piles. After that, intermediate support columns are installed. Work is better to exercise together or threesome. For the screwing, you will need a rod inserted into the upper holes of the pipes. A lever must turn out, with the help of which the pile rotates.

During the rotation every 4-5 revolutions, the correct vertical position of the piles is checked. If they won't be vertically, the foundation will not be able to withstand the planned load. The screwing process ends when pipes immersed on the necessary depth. The completion of the work also indicates the maximum resistance of the soil.

When making installation works, it is prohibited to unscrew the piles to align the horizontal surface. This is due to the fact that over time the design can be asked as a result of the bursting of the soil.

If the pillars stumble upon an irresistible obstacle, then you can solve this problem in two ways:

- screw the pipe elsewhere;

- change the estimated length of piles.

If the silent itself fell into unstable soft soil, then it must be deepen. In the case when there is not enough pipes along the length, you will have to boil another piece on it. Naturally, this procedure is not recommended to be carried out with several consecutive pile, mounted close to each other. It is fraught with a decrease in the bearing capacity of the foundation.

The fill of the concrete solution inside the piles pursues one goal - preventing the corrosion of the inner surface.

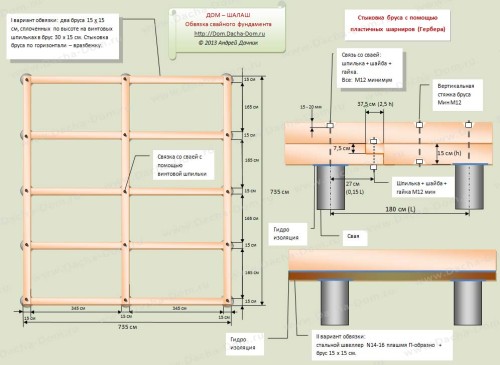

Stopping the foundation on screw piles

For the strapping of the pile foundation can be used both a wooden bar and a metal chaserler. Naturally, the bruse strapping is carried out with the subsequent erection of a wooden house. If the building is brick, gas-silicate or foam concrete, then it is better to use the metal strapping.

An integral element of the strapping - pile headband. It is a flat metal platform (10 * 10 or 30 * 30 cm), welded to the pipe. The weld is covered with an anti-corrosion mixture and paint.

With a wooden strapping on the heads, waterproofing material is settled. Only on top of it the wooden bar is stacked. Horizontal structural elements are connected by writing in half a tree and fixed with nails.

When the cutting of the metal is built, the chapeller is mounted on the ledges, and the 2-way beams on the lower shelf. In places of metal compounds in the corners, under the angle of 45 ° is carried out. All elements are welded with a double seam. In order to maximize the welds from cracking, the blockage is additionally enhanced by bolts.

As for the price of the foundation on screw piles, it ranges from 60 to 90 thousand rubles. On average, one pile costs 3 thousand rubles. For a small country house with an area of \u200b\u200b35-40 m², 20-30 pipes will be required.

Video on the bookmark of the foundation on the screw piles: