For the wells, special rings are used, which are made from different materials and can have various design features. In this article we will talk about the types, properties and characteristics of concrete rings and give recommendations for their choice.

Content

Types of wells

Wells are classified by appointment and constructive features, distinguishing the following types:

- Drinking wells - structures designed to fence water suitable for drinking or any household needs. They are always equipped with a device for lifting water to the surface.

- Water wells - have inside all the necessary equipment for the operation of the water supply.

- Drainage wells are used to control and washing the drainage system, while at the same time act as a tank for collecting dirt and sand.

- Weightful wells are needed to keep track of the sewer and warn her clogging on time.

- Telephone wells are needed for laying communication networks.

- The wells of the gas pipeline - are placed with strict observance of the GOST.

- Celley wells are used as peculiar sewage and also require compliance with certain rules of the device.

- Storm wells are needed for removal of rain and melt water.

Tops of rings for wells

Rings, as mentioned earlier, are made from different materials and may differ in the type of construction. Depending on the material there are such types of rings:

- Reinforced concrete - with the help of such rings do wells for laying communications: sewage, water supply, drainage system. They perform the features of the protection of these systems from any negative external factors. Each type of well matches its kind of concrete rings.

- Plastic rings are considered more durable than concrete. They have good tightness and do not spoil from water.

According to the constructive features of the rings for wells, there are such:

- Plastic rings with a tray in the lower part are invented to direct the flow of water in the desired side, thereby avoiding its delays in the well.

- Wall rings are used when creating round wells, for example, a sewer tank or pipeline. The diameter of them, as well as height, can be completely different and are selected for a specific structure.

- Dobly or auxiliary rings are distinguished by non-standard dimensions and are made under the order.

- Prefabricated rings are used to improve wells of well-defined sizes. Such rings can be concrete or plastic, the latter are divided into smooth and corrugated. The wells made from the prefabricated rings are considered expensive, but they can be done completely any height. There is also a minus in the deep structures, the strength of the walls may suffer.

- Rings with a bottom - these are monolithic structures, the advantage of which is the absence of risk of leaks.

- Rings with lock - used to seal joints between simple rings. As a result of their application, the design is more durable, its parts are not shifted relative to each other.

- Rings with a slab of overlapping, as a rule, are made from reinforced concrete and perform the function of the final part during the arrangement of deep wells.

The height of the rings for wells is different. Popular parameters: 290 mm, 590 mm, 890 mm and 1180 mm. The diameter of concrete rings varies within 70-200 cm.

Benefits and disadvantages of concrete rings for a well

If we talk about the advantages of concrete rings, then it is worth highlighting the following:

- installation of structures is performed in a short time;

- stand rings from reinforced concrete relatively inexpensive;

- their installation to each other provides good strength and tightness of the joints;

- the well made of concrete rings is distinguished by strength;

- the service life reaches several decades.

But concrete rings for the well have a number of shortcomings:

- they weigh quite a lot, which complicates both their transportation and installation;

- when installing the rings, you need to use the installation technique, and this is additional costs;

- you can only carry concrete rings using vehicles;

- if the installation was incorrect, and an uneven load acts on the wall walls, cracks may appear in the rings.

Concrete rings for well, photo

How to choose concrete rings: useful tips

- If the well is designed to fence drinking water, rings must be responsible for all hygienic standards.

- When buying it is necessary to check the quality of the reinforcement of the blanks. Good reinforcement is the presence of a wire mesh in the material. To date, there are poor quality rings in which instead of the grid there are only a few rings out of the wire.

- Rings must match the desired size and forms.

- Concrete must be durable, have a good hardness.

- By purchasing concrete rings for a well, check the availability of product quality certificates from the seller.

How to make concrete rings for a well do it yourself

Making form

To make a concrete ring, it is necessary to create a form at first. The form can be made of metal barrels.

- First, locate 2 thick-walled barrels of different diameters. Big will be responsible for the outer diameter of the product, smaller - for internal. Be sure to take into account the fact that the finished ring, and therefore the outer barrel must coincide with the diameter of the future well or be slightly less than it. The difference in diameters should be about 15 cm.

- Working with barrels will be easier if you cut them and secure the door loops. To do this, finish the bottom of each barrel, and make an internal blank above the external 10 cm. Then, spend two longitudinal markups on each barrel. By these markups, install two doorways so that the bending loops passed on top of the marks and along them. Fix the canopies with a welding machine or attach them to the barrel rivets for metal.

- To the thickness of the walls of the future rings everywhere was uniform, install several struts inside the design. Put a smaller barrel to the larger, measure the distance between them in a circle, align and drill in several places of the hole for the studs. Stiles in this case will serve the segments of a metal rod. On each side of such a segment it is necessary to make a thread. The holes in the barrels are done opposite each other, then they screw the studs in them and tighten into nuts, thereby fixing parts of the form.

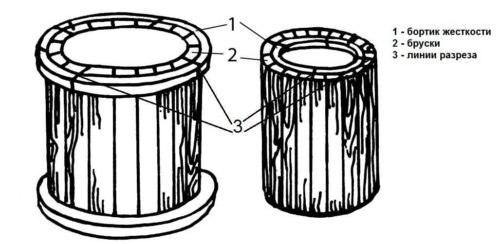

If the barrels in the farm did not turn out, you can make a formwork from sheet metal. This is done in this way:

- Take a metal sheet and cut the band of the desired size. Its length should be equal to the length of the circumference of the future ring plus 10 cm on the edge connection. The width of the sheet will be the future height of the ring minus 10 cm on flights.

- On top and bottom of the form you need to make fires 5 cm, along the edge of the strip also need a side of the same size. From the side to drill holes for the bolts to pull the metal into the ring. Top side care every 20-25 cm or less, depending on the ring diameter. Bend the metal and torn the bolts.

- The framework of wooden bars will help to give stiffness. Cut them with fragments of 20-25 cm and install under the side, attaching the screws through the metal. Then install wooden bars vertically along the entire ring, so that the walls of it were durable and not bent.

Someone work with wood is lighter, so the shape for concrete rings can be made of wood. For this purpose, narrow bar are suitable. They must be collected like barrels and secure metal rings at the top and bottom. Outside the greater formwork and inside the smaller also need to make sides.

Remove the finished ring will be easier if the form is pre-lubricated. For drinking wells, you need to choose safe lubricant, such as vegetable oil. But for technical wells, you can use machine oil mixed with working out.

Concrete fill in forms

By making a shape for rings, you can proceed to their direct production:

- Prepare sand, cement, water and crushed stone in the desired quantity. Also find the concrete mixer, lift or crane.

- Mix the cement with sand and water, prepare a concrete solution. Soak rubble and add to the solution, mix thoroughly.

- Put the shape on a flat flat surface inside the formwork, install the valve from the grid or wire.

- Fill the concrete mass between the shape walls and leave to stick. When the ring becomes solid, remove it from the formwork and stand another 30 days.

- Make measurements, and if everything matches, the ring can be used for mounting.

Installation of concrete rings

Installation of the rings for the well is carried out like this:

- It requires several people. At first, in the selected place, the pit of the desired depth is digging and the first monolithic ring is immersed in it. Immediately check the mechanism of installation by bubble level. Dissolves are eliminated immediately, dumping the soil in the right places. If irregularities are not eliminated, all subsequent rings will also become on top of each other with distortion, which will affect the strength of the structure.

- In this way, concrete rings put on each other, each time checking their vertically with a plumb and correcting the shortcomings.

- Fixed rings, causing concrete solution.

- The final stage on the well is mounted slab with hatch.