Pollination of polyurethane foam (PPU) is an innovative method of thermal insulation, which consists in filling out the material of the building wall cavities. This technology is used for thermal insulation of buildings of various purposes - residential buildings, industrial enterprises, office space.

Content

Features of the application of material

Polyurethane foam in its physical properties is a plastic thermosetting mass having a cellular structure. The strength of the material gives the crystalline solid structure, which is 3% of the total mass. By 97%, the mass consists of pores and cavities filled with gas, characterized by low thermal conductivity. PPU is formed as a result of mechanical mixing of components. In the course of this procedure, two components come in one chamber and mixed. In this case, it is necessary to eliminate the presence of compressed air.

Polyurethane foam composition at the exit has the form of an elastic smooth jet. At that moment, when the contact between the two components occurs, a chemical reaction is carried out, the result is the formation of polymer polymer. In the reaction process, carbon dioxide and heat formation occurs. Carbon dioxide contributes to the formation of a porous structure, and under the influence of heat, polyurethane raising. As a result of this process, polyurethane foam is formed.

Sphere of use of Polyurethane Polyurethane

The PPU has good sealing properties and is widely used for processing thermal seams in panel houses, as well as in the field of road construction. In addition to its main function, which consists in creating a heat-insulating effect, the use of polyurethane foam allows you to solve several more important tasks for the operation of the building. With it, high-quality sound insulation is provided, the walls also obtain a protective coating, which prevents the damage to the material as a result of the effects of external negative factors.

An important quality of polyurethane foam is the possibility of its use in those places that cannot be insulated with other materials due to the structural features of the building. For example, the processing of such gaps where slaughter and rolled insulation cannot be applied. And thermal insulation using granular materials will require dismantling the wall or roof fragment.

In addition, the use of PPU allows you to improve the appearance of the wall and get rid of various defects. And due to the elasticity of the material, in the event of a shrinkage of the structure, the insulation will not crack and keep fully its qualities.

Advantages of using PPU

- Among all materials of similar purpose, the PPU is characterized by the lowest thermal conductivity coefficient.

- The coating has a monolithic structure in which there are no slots and seams.

- Quality noise insulation.

- Material has neutral biological indicators.

- PUP is resistant to the appearance of various fungal formations and mold, and also does not represent interest for rodents.

- The material has a long service life - 30 years and more.

- The possibility of applying in hard-to-reach places.

- Material retains its thermophysical properties throughout the entire period of operation.

- Parry permeability, resistance to mechanical effects.

- High properties of adhesion.

- No shrinkage.

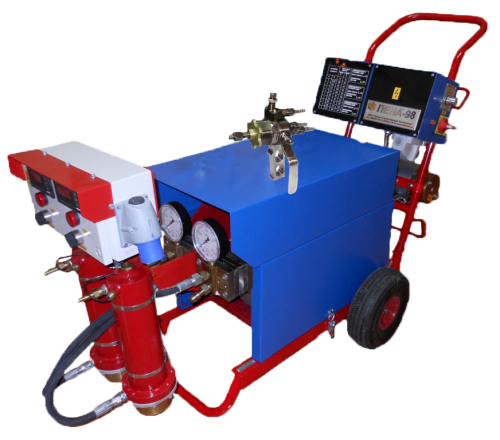

Principle of operation of equipment

Equipment for polyurethane foam is divided into three categories by type of application. According to this criterion, installations are distinguished, which in the course of work are carried out:

- high;

- low pressure;

- foam generators.

Models operating at high pressure during application does not apply compressed air. This type of equipment has a number of benefits:

- high performance indicators;

- dosage accuracy;

- ease of operation;

- mixing components is carried out at a high level, which positively affects the quality of the material;

- PPU can be sprayed with small portions;

- thanks to an airless method of applying, the formation of fine particles is reduced to a minimum.

The disadvantages of this equipment include the complexity of the service and the high cost of component materials.

The work of low pressure equipment is to use compressed air. The advantages of such installations are as follows:

- low cost of components;

- ease of maintenance;

- easy design.

As a lack, you can select a large consumption of material and not fairly accurate dosage.

A separate category includes foam generators that produce mixing components by air supplied by special compressors.

Characteristics of installations for filling PPU

Equipment for filling polyurethane foam UZK-20 and narrow-10 has a high productivity at relatively small sizes. These installations allow you to perform both fill and spraying the material. The devices are equipped with an upgraded casting head, which in addition to a long service life and reliability is characterized by smoothly regulating performance. Also, the equipment is equipped with a timer that allows the PPU to be supplied in the form in the required quantity. The small weight of the structures simplifies their operation. These installations can easily move one person.

The package includes a spray gun that allows you to perform high-quality spraying. The reliability of installations is provided by a three-phase motor. The control panel contains the performance and remote control panel. The presence of a digital timer makes it possible with accurate mass definition and the volume of the final item to install the time required for filling. This feature allows you to prevent overflow or nothing the material and thereby significantly reduce its loss.

Also at the production of casting installations specializes in the company GK Rosteplozolation. The company's products include such models as: PGM-75At, PGM-45At, PGM-30T. These aggregates have in their configuration of the tanks of high capacity, which have the function of automatic heating of the material. They make the fill with the method of molded products with a volume of 0.4 m 30.6 M. 3 and 1 M. 3.

The company also specializes in the production of universal equipment. That is, installations with which in addition to the fill you can perform and spraying. It is PGM-10A, PGM-10BN, PGM-18M, PGM-18C, PGM-20At, PGM-20BN, PGM-27M, PGM-27C, PGM-36M, PGM-36C. Such installations are characterized by simplicity of the design and the possibility of setting the necessary proportions of the material.

Features of the technological process

Polyurethane foam is made at the construction stage and after its completion. In the elevated building, the insulation of walls with the help of PPU is performed in the following order:

- In the wall with the inner and the outer side, holes with a diameter of 10-15 mm are drilled. The holes must be drilled over the entire wall surface in the vertical and horizontal direction after 60 cm.

- Next, starting from the bottom up, the hole is supplied to the hole. By filling out one level, you should proceed to the next and thus treat the entire wall.

- The technological order of fill from the lower direction to the upper point is due to the result resulting effect. With this approach, the material is evenly distributed across all the cavities, which eliminates the formation of gaps due to the presence of which it would be warm out of the room. Also, polyurethane foam completely filling all cracks, contributes to the strengthening of the wall and increase its strength. Spraying polyurethane foam is performed under high pressure through special equipment.

- A gun equipped with a special nozzle delivers material inside the wall. The PPU is in the liquid state, spreads along the bottom. After that, the material foams and fills the entire cavity. The process of foaming is carried out by the smallest resistance. This is of particular importance when working with brick masonry, since thanks to this foaming, the free space is filled, but it does not extrude the masonry. For frosting polyurethane foam requires 1-2 minutes. After that, the material forms hermetic, dense coating.

Pamp Filling at the construction stage is carried out as follows:

- During construction, the space is observed to fill with thermal insulating material.

- Pouring is made 1.5 meters all over the arms. In this case, certain PPU grades are applied with reduced density. This material is not frozen, but after a certain period of time expire, everything is evenly filled with emptiness.

- In addition, the weight of this insulation is small and as a result of its use, an additional load on the bearing walls will not be created. During the operation of the house, this nuance is also important.

Conclusion

Polyurethane foam is allocated among other materials that have a similar appointment with a significant amount of advantages. The use of this composition is quite simple and carried out by special high-tech equipment. Today manufacturers offer a wide selection of installations that make it possible to get a good result without spending a lot of effort.

The insulation process of polyurethane foam on video is shown below: