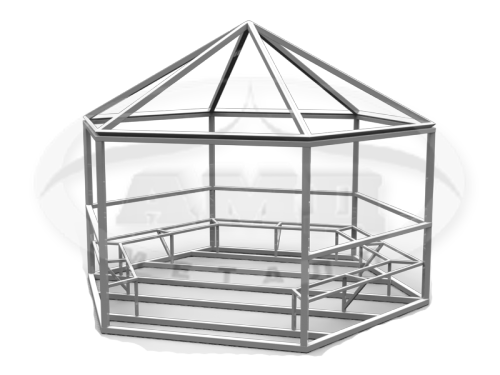

The gazebo is an integral attribute of a well-kept country site. Summer kitchen, dining room, living room, recreation area - all these functions can perform a gazebo. This design can be built from various materials. Now we will tell about how to make a gazebo of polycarbonate.

Features and advantages of material

To build a summer gazebo from polycarbonate, it should be used by the cellular (cellular) variety of material. The cellular polycarbonate should include a special film due to which the material will be absolutely resistant to mechanical loads.

The cost of cellular polycarbonate is below the monolithic. In addition, it can be bent. Bending radius is usually indicated in the instructions that are attached to the material. If the bending radius is non-compliance with the polycarbonate can break.

In the process of drawing up a drawing of a gazebo from polycarbonate, it is necessary to take into account the fact that the canvas have rigidity ribs. Stiffness edges should be placed in such a way that moisture is not delayed on the polycarbonate.

The advantages of cellular polycarbonate include:

- high strength;

- smoothness of the material (snow and water is not delayed);

- ability to delay ultraviolet rays;

- incompetence of rotting and rust coating;

- resistance to temperature differences;

- absolute fireproof;

- variety of shades;

- simplicity of installation work;

- easy to drill and cutting;

- attractive appearance.

It should be mentioned that there may be completely different and the size of the gazebo of polycarbonate. This makes it possible to create a design, absolutely not similar to standard samples.

Location of construction

Polycarbonate gazebos for giving can be mounted in any part of the country area. But still, when the capital construction is constructed or it has a large area, it is recommended to adhere to several conditions.

Main conditions:

- the presence of a smooth and dry surface;

- low groundwater occurrence;

- lack of drafts.

It is desirable that the gazebo with the roof of polycarbonate was located near the trees. In sultry summer days it will not be too hot. But the main condition (especially relevant for regions with high humidity) is that water should not accumulate in the place of construction after the abundance of abundant precipitation.

Carcass device

For high-quality construction with your own hands, gazebo from polycarbonate should be paid to the arrangement of a reliable framework. Naturally, the installation of wooden support columns will be much cheaper. But wood has many drawbacks:

- rapid loss of the initial type;

- provision of regular care;

- the probability of swelling or drying.

In connection with this, the best option for the design of the framework will be the use of support elements made of metal. This design will be characterized by maximum strength and minimal care.

Universal material for the manufacture of a metal frame in a gazebo with polycarbonate are profile pipes that have a different cross section. Profile pipes are used in the arrangement of walls and roofs of the structure:

- cross section 4 * 4 cm as reference racks;

- 4 * 2.5 cm - for roofs and basic jumpers;

- 2 * 2 cm - for the construction of auxiliary jumpers.

The process of creating a carcass itself involves the implementation of such actions:

- Drying six pits: Four - for columns in the corners of the gazebo from polycarbonate, two - at the entrance to the construction.

- For maximum adhesion with concrete solution, metal liners are brewed for one end.

- In the dumped holes there are fixation of the support columns. For the correct location of the racks in terms of the level, you can use any retaining materials.

- After a thorough check of the correctness of the location of the pins of the pit is poured with concrete solution.

- Further work is embarking on 3-4 weeks after concreting columns.

At the next step, welding pipes with a cross section of 4 * 2.5 cm, with the help of which the support columns are connected. This procedure is carried out at an altitude of 1.1-1.3 m from the surface of the Earth.

The pipes not only connect the columns, but are the basis for the subsequent attachment of the wooden railings or the plating with the same polycarbonate. The only nuance - the welding of pipes is not made between the columns at the place of the future doorway.

Next, the welding of pipes is carried out in the upper part of the wall of the structure, where the roof of the polycarbonate will be adjusted. At this stage, it is planned to create a slope that is needed for normal drainage. To achieve this, you should:

- place two pipes horizontally, but at different levels;

- side tubes are placed under the tilt.

After the framework of the frame, all protruding pipes are cut with a grinder. To prevent water from entering inside the design, the holes arisen are brewed with pieces of sheet metal.

Next stage - Installation of the roof crate to which polycarbonate will be mounted. At the very beginning, profile pipes are mounted in the top row. The distance between the pipes should be so that the polycarbonate sheet is without any problems in width.

In most cases, the work begins with the central part of the roof with a gradual movement in both directions. The installation of polycarbonate sheets occurs in a similar way.

After installing the carrier ribs, they are connected by transverse jumpers. Due to this, the gazebo from the polycarbonate will be withstanding the weight of snow with heavy snowfall in winter. Installation of transverse jumpers is performed in the upper part of the supporting pipes at a distance of 0.9-1.1 m from each other.

If desired, the lower part of the structure under the railing is also squeezed by polycarbonate. This will be a reliable obstacle from the gusts of the wind. After the framework of the frame, it should be treated with primer and paint.

Mounting work

In order for the gazebo of polycarbonate in the photo and in fact absolutely similar, special attention should be paid to the high-quality cutting of the material and drowning holes for fasteners.

Polycarbonate sheet marking is carried out with a wax chalk or pencil. All nuances accommodate fasteners and other parts are taken into account. To cut the material, you can use any cutting tool starting from a conventional knife and ending with an electric logger. Immediately there are points where the polycarbonate sheet will be shrinking with profile pipes.

The best fasteners for the installation of polycarbonate are metal screws (texes). They have a hexagon head with a press washer and a gasket made of rubber. When attaching polycarbonate, the screws can not be very tightened. Otherwise, the casing can split.

The connection of sheet parts is carried out. This is explained by the fact that when fixing the details of the jack, the obtained slots will be filled with water. It is possible to give ease and transparency by a gazebo by cutting in the walls of the ornament. When sunlight enters the curly holes, the design acquires a more openwork form.

To give a more correct direction to sheets of polycarbonate, they can be laid in a special profile. The profile installation is carried out on both sides in such a way that the polycarbonate is inserted without effort into adjacent profiles. After that, the trimming material is attached to a metallic base with a step of 0.4-0.5 m.

Despite the fact that the profiles from the end part cover the inner part of the polycarbonate, the inside of the material is quite large amounts of dust. Over time, it accumulates and worsens the appearance of the arbor. To prevent this, you should use silicone sealant.

There is another polycarbonate mounting technology, which is used when creating a scope or flat roof. It is applied much less frequently and is called a wet way. Installation work provide:

- frame device;

- coating with polymer mastic;

- pressing polycarbonate to mastic to its complete drying;

- sealing of joints and ending elements.

When working with polycarbonate sheets, such recommendations should be followed:

- Installation work is carried out only in windless weather. Otherwise, there is a likelihood of polycarbonate damage. It will be difficult to fix the sheets with severe wind gusts.

- The drilling of the holes is carried out between the ribs of the canvas. It is not recommended to drill holes at a distance less than 4 cm from the extreme part of the sheet.

- The lower end portion of the polycarbonate is not closed by the profile. Moore should go past them.

- After the final fixation of the polycarbonate, the chips and dust from the inner cavities are removed.

- When arched design, it should be envisaged that the ribs of stiffness are directed along the arc.

- When choosing a material, it is necessary to consider that colored sheets are heated and expand to a greater extent than transparent material.

The final stage of the construction of the gazebo from polycarbonate is the arrangement of its internal space. Original tables and chairs, various decorative elements (live flowers, tablecloths, floor lamps, lanterns) will add a stylish modern look. If there is a desire and the possibility, then we can engage in the construction of gazebos from polycarbonate with a mangal.

Video on the construction of a gazebo of polycarbonate: