It is difficult to present comfortable accommodation in the country house in the winter without a heating system. One of its integral elements is chimney. Our article we will talk about how to make a chimney of bricks.

Content

What is a chimney of bricks

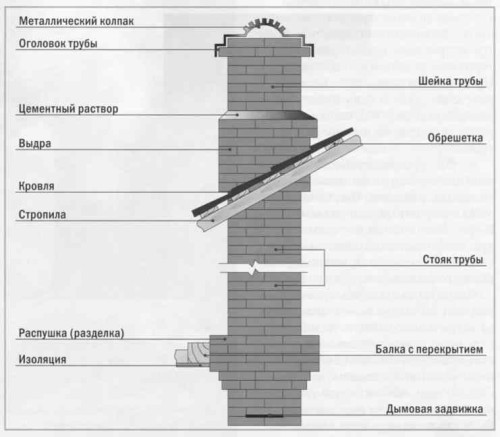

If someone thinks that the chimney is an ordinary pipe, he is mistaken. This design consists of the following parts:

- nasadny pipe;

- roller

- riser;

- otters;

- necks;

- podle.

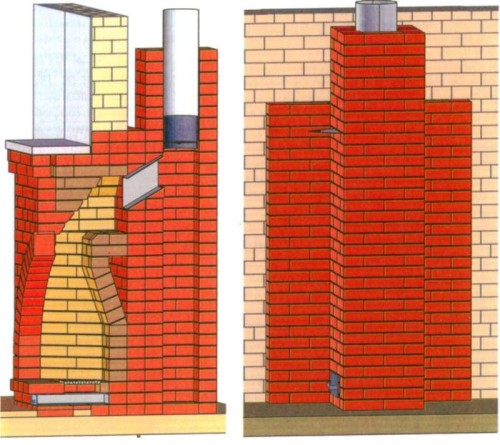

The housing tube is an initial structure in the chimney scheme of a brick. It is located on top of the fireplace (or furnaces). The laying of the onset tube is made with a mandatory dressing of each brick series. Usually 5-6 rows for the device of the housing pipe. The only nuance is that this part of the chimney should not touch the inter-storey overlap.

After creating a housing tube, the rush is laid out. There is a slight expansion of the outer part of the chimney (up to 25-40 cm). Its internal dimensions remain at the same level. After the roller, there is a riser that takes the space from the attic to the roofing system.

Under the device, the chimney is again expanding from the outside on each side of approximately 10-12 cm. The main purpose of the otter is the protection of the roof, carrying structures, overlaps and the attic from atmospheric precipitation.

Next constructs the cervical tube. The technology of its masonry is similar to the rising device. At the final stage of the chimney of the chimney from the brick, the cauldron is created. The masonry is expanding, and the deflector or metal cap is installed on top of it.

Choice of bricks

To ensure the absolute fireproof of the chimney, the masonry material should be correctly selected. What kind of brick is needed for chimney? It should be:

- baked;

- refractory;

- full-tempered.

For the chimney device, a brick can be used, which has a different firing stage:

- well burned;

- inexpensive;

- deceived.

Distinctive features of well-burned brick:

- red color;

- smooth edges and wall;

- metal szvuk when climbing brick.

The inexpensive brick has pink color. When tapping on it, it turns out a deaf sound. The checked brick has dark brown shades.

For the masonry of most sections of the chimney, a well-burned brick is used. From the checked material lay out the foundation. Alone brick is applied to create less important sites.

Calculation of the optimal characteristics of the chimney

The formation of a permanent movement of air flow from the bottom point to the upper (traction) is achieved by means of pressure drops and temperature regime. It is due to the pulling the correct functioning of the chimney.

The chimney design should be characterized by good aerodynamics and a smooth surface of the walls. Only so smoke will rise to the highest point without twist.

For this reason, the closest attention is paid to the accurate calculation of the diameter of the structure, in which the main requirement is performed: with an increase in the length of the chimney, the thrust should be improved.

Not the last place in creating maximum thrust and ensuring the uninterrupted functioning of the heating system in the winter time occupies the number and size of chimney channels. The magnitude of the diameter of the chimney channels is influenced by the power of the boiler or other equipment, which will be used for home heating.

With substantial exceeding the diameter of the channel over the calculated indicator there will be a significant reduction in thrust. As a result of this phenomenon, heating devices will work with permanent interruptions. If the size of the chimney of bricks will be less than the optimal value, it will lead to a complete stop of the boiler.

The minimum amount of the internal section of the channel should be 14 * 14 cm. When using round elements, the chimney diameter should exceed 15 cm. When constructioning of a structure with a height of more than 5 m, the diameter of the channels should exceed 18 cm.

Creating chimney channels is recommended to be carried out in heated rooms. So they will be protected from excessive cooling, which causes a reduction in thrust. It should also be used to ensure that the chimney channels in more quantities are located above the roofing material. What will significantly improve the efficiency of the chimney.

Based on the construction norms, 1 kW of the power of the heating device must correspond to the area of \u200b\u200bthe chimney cross section of 8 cm². Suppose if the cross-sectional area of \u200b\u200bthe brick design is 300 cm², then the boiler power must be up to 38 kW. Such equipment is quite suitable for home heating, which has an area of \u200b\u200bup to 350 m².

Preparation of masonry solution

To create chimney with your own hands, you will not need cement. For these purposes, sand and clay should be used.

There are a number of requirements that are presented to the components of the solution for masonry bricks. For example, it is recommended to use river sand and clay, mined from a depth of 1.4-1.6 m. The clay must be clean, without garbage and other impurities.

The preparation procedure itself consists of the following steps:

- careful sifting of clay and sand through the sieve with cells not more than 5 * 5 mm;

- mixing 1 piece of clay with 2 sand pieces;

- adding water to the mixture (approximately in the ratio of 1 h. mixtures and 4 hours of water);

- insoleting the solution for 10-12 hours (so that the solution is ready for the morning, it can be used in the evening);

- after complete "deoxidation" of clays, the finished mixture is mixed with a construction mixer to sour creation consistency.

Laying smoke

Now let's start directly to how to put the chimney from the brick. The process is not too complicated. Just need to observe several technological nuances.

Nasadny tube

Begins the process from the device of the nasadny tube. Over the outlet of the fireplace (or furnace), the series of 4-6 bricks with the creation of a cavity for the channel will be caused through which combustion products will be output.

A specific number of bricks in a row is determined based on the power of the heating equipment. If the boiler power is up to 3.5 kW, then a channel made of 4 bricks is enough for the device of the housing pipe. At a higher power capacity, it is better to use 6 bricks masonry.

The optimal dimensions of the housing pipe should be:

- internal - 27 * 14 cm;

- external - 59 * 45 cm;

- the width of the seams should not exceed 1.5 cm.

The correctness of the stacked vertical rows is checked by a plumb, horizontally - using a construction level.

Laying Flap

To create a reliable roller, use the metal bar, which is strengthened by the whole design. Their installation is made in such a way that the chimney canal does not overlap.

Masonry increases by one brick. If at the bottom of the chimney consists of 4 bricks, then 5 bricks are used for the roller device. Moreover, the process begins with styling of halves or quarters.

Bricks of the new row should hang a little on the extreme part of the previous series. The third row also increases the size of the roller. The chimney cross-section becomes equal to 65 * 51 cm. To prevent an increase in the diameter of the channel, brick plates are inserted into the inner part of the chimney with a thickness of up to 6 cm.

After laying the fourth row, the exterior sizes of the design should be within 71 * 57 cm. The fifth and sixth, the flush end. In the fifth row there are laying of two whole bricks next to each other. In the sixth row, bricks are shaped similarly. The only difference is the presence of dressing.

Riser and otter

The creation of the housing tube and the roller ends work inside the residential premises. The chimney laying is made in the attic where the rising device is performed. In the roofing material, a hole is pre-done, which is intended for the output of the chimney into the street.

For the construction of the riser, it will not be necessary to conduct any settlement work or increase (decrease) the size of the chimney. Two rows of riser must rise above the roofing material. After that, the creation of otter begins.

There are the following nuances of creating this part of the chimney:

- in total, 9 rows are laid out;

- in size each subsequent row wider than the quarter of the brick of the previous series;

- the increase in the size of the design is carried out first in width, and then - in length;

- the sizes of the internal channel must remain unchanged.

For successful implementation, internal brick plates are adjustable in practice. Laying bricks occurs so that only one step in front of the front part is obtained. At the edges, the size of the chimney should not change.

The third row of exhaust is done wider (by nulling bricks). Their front protrusion should go over the side of the bricks of the previous series.

Laying the fourth and fifth brick rows occurs in such a way that the side protrusions increase in length. It is in these ranks that the clearance is begun, which is made between chimney and roofing material.

The bricks of the sixth row completely overlap the gap, and the seventh row finally generates side protrusions. After laying 7 rows, two side and one front protrusion should be. Creating rear speakers is carried out in the eighth row. The main requirement is to carry out bricks dressing. Moreover, the use of brick plates should not change the external dimensions of the chimney.

Cervical and headband

With 9 rows of otter, the laying of which is carried out similarly to 8 row, actually begins the creation of the cervix. 6-8 brick rows are enough for its device. The main condition is compliance with the rules that relate to the height of the chimney over the skate.

The brickwork is made in the same way as the roller was created. The upper part of the head closes with a deflector (or cap), due to which the thrust improves and the chimney channel is protected from precipitation.

Several recommendations

There are a number of requirements that are presented to the chimney of bricks for the boiler. In most cases, they depend on the type of fuel used for the heating of the room. The combustion temperature of various fuels can range from 100 to 400ºС.

The basic requirements of the device of the brick chimney canal include:

- Absolute tightness when exposed to high temperatures. Combustion products should not fall into residential rooms.

- In the vertical chimney there should be no extensions and narrowings. The deviation from the vertical plane of the structure is allowed only within 3 cm per 1 m length.

- The strength of the brickwork depends on the thickness of the seam. Than he thinner, the stronger the chimney.

When using a gas boiler, a brick chimney is necessarily equipped with a steel or ceramic liner. The liner is inserted directly into the channel when carrying out masonry.

The wall creates a hole for cleaning the combustion products and a condensate sump. The liner does not need to be close to the end. Between it and the wall should be a gap, thanks to which the liner will be shifted without any problems.

Special attention is paid to the height of the chimney. There are the following norms for its exceeding the roofing skate:

- 0.5 m - with a nearby ice skate (up to 1 m);

- more than 0.5 m - when the chimney is at a distance of 1-3 m.

The minimum height of the chimney, built for gas heating, is 5 m.

Video about creating a brick chimney: