Ceramic tile due to its aestheticism and durability today is one of the most common finishing materials. During its laying, it is practically impossible to do without cutting. To do this, use different tools, among which a special place occupies a tile car. In order for the work to be performed efficiently, it is important to know how to choose a stoveture. Its selection depends directly from the characteristics of the tile itself. Therefore, you first need to pick up the appropriate material, and then choose tool for it.

The tiles can be used to cut almost all types of tiles, including for tiled, stone and porcelain tiles. They can be cut, both facing and outdoor tiles. It allows you to make a cut not only at right angles (90 degrees), but also under smaller.

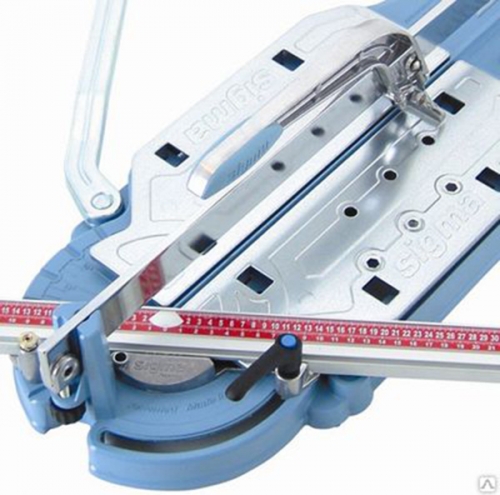

Modern stovetur consists of:

- cutting element

- floating base

- coromet

- one guide.

The most important detail in it is a cutting roller made of hardwly steel. Platekores designed for porcelain stoneware can no special problems cut the tile from this material, and high quality and fast. No other tool, even with the help of a grinder, one cannot achieve this quality cutting.

Distinguish plates:

- Manual. Designed for home repairs.

- Electric. Suitable for large-scale work.

How to choose manual stove

Characteristics of manual slabcoresis

Such a device can cut the tile to one and a half centimeters without any problems. Some tools are equipped with the so-called "ballet" required to cut holes. Sometimes this thing is really necessary, but you should know that on the cheap models of the "Balkerinki" slab cutting models very badly perform their functions. This feature is well thought out only for professional models. Therefore, if you need to do holes in the tile, you should buy only such tool models.

Unfortunately, all, even professional tiles, have one insignificant drawback. It lies in the fact that the tool can not cut off the tile edges small pieces of 4-5 millimeters width. For this purpose, water stoves are usually used, special nippers or, in the extreme case, Bulgarian.

Tools Tools

- First of all, it is worth paying attention to the strength of the frame. If the frame is weak, then such a tool cannot be used even for the work of the middle volume, it will quickly come into disrepair.

- Take into account when choosing a tool, that on its strength and durability affects the thickness of the metal thickness directly. The quality of the device also shows the presence of a tough and sustainable base. The strength of the instrument handle is affected by the lever. Pay attention to this when we decide which slab should be chosen.

- The next parameter to pay attention is the length of the tool. It is not necessary to acquire a short slab, even if the price for it is much more attractive and lower. Better buy a universal tool that will be equally suitable for performing different types of tasks, including cutting tiles, both for walls and for floors. This tool will have to be likewise, by the way when laying the tile diagonally.

- An important characteristic of any stoveture is its smoothness. It is achieved thanks to a special bearing. Although not all devices are equipped with such a bearing.

- Before using the tool in the work, it is recommended to test it. The gliding of the slab should be smooth. If this is all taken into account, then you know how to choose the right tiles. So you can safely buy such a tool. Costs will be accumulated.

- The main part of the manual plate is the cutting roller, made of hardwly steel. If this video is blunt, then the tool will cut very badly. Moreover, this video cannot be sharpened, it can only be replaced. On some devices there is a swivel ruler. It helps cut the tile at an angle.

- In the plotting discovered under well-known brands, it is possible to adjust the thickness of the material being processed with which it is necessary to work. This makes it possible to limit the course of the rolling paws. This prevents the edge to be prevented, even if you cut in a diagonal direction. But it should be borne in mind that such plates are not seeing.

High quality hand tiles from famous brands

Consider several tool models from well-known manufacturers to pay attention to. This will help you decide which manual slab should choose.

RUBI TM-70

- Rubi has quite a lot of sticker models. TM-70 - is one of the most popular. It is equipped with a high-power adjustable separator. They can cut the tile without any problems, both from ceramics and out of porcelain stoneware. You can use for threads of large-format ceramics.

- This model has chromed all-hand guides. Separately can be fixed from 6 to 21 millimeters.

- There is also a side limiter that allows you to perform repeated cutting at an angle of 90 and 45 degrees. The size of roller cutters is 8-22 millimeters.

- If you are looking for a tile cargo in which the price is combined with quality, then this tool is most likely suitable for your requirements.

- Rubi's price range is quite large. There are both models for an amateur and for a professional. Alternatively, it is possible to consider the Corvette plates.

Matrix 600mm

- This is a single 600 millimeters long-range slab. The guide rail in this model is represented in the form of a foreign rail made of steel alloy. The carriage is driven by a ball-bearing mechanism.

- To regulate the clamping girth there are special bolts. Thanks to them, the stoveture has almost no backlash. It allows you to achieve maximum sustainability during cutting.

- The ball has a good clutch with the bearing, which is achieved due to the special coating. In addition, the coating makes it possible to exclude the crawling of the carriage.

- One of the features of Matrix tiles is a very light handle. This model also has this feature. In addition, the tool has a bed of aluminum, which makes it easier to work and makes it more mobile.

3cm Sigma.

- The separating power of this stoveture is 1150 kilograms. Thanks to this such tool, you can cut even the most complex materials.

- You still need to mark a special handle-separator, which is equipped with a ball bearing and shock absorbing device. Thanks to this handle, a high power, smoothness and smoothness are combined in this Sigma tile.

- In addition, this model has a wing-base structure made of galvanized steel. Pretty conveniently located a centered line. It is located near the tiler. In this case, it can be quickly fixed enough at any angle. As an alternative, it is possible to consider the ZUGR tile.

Montolit 26pb.

- Montitol places can be used for a large amount of work. And no matter what strength and what size tile. This is a tool for real professionals.

- Due to the rigid design of the model from the montolite, make it possible to do almost perfect cutting without any deviations. Even if you deal with very durable ceramics using a high-strength cutter, you can perform sufficiently deep and even cuts.

- These stoves give a very good quality of the chip on the material with a thickness of up to 25 millimeters.

- In addition, the tool is equipped with the options for setting the thickness that allows you to adjust the foot of the paws. Due to this, when cutting, the material will not crumble.

Stayer 3310-60

- All varieties of Stayer Playcore are representatives of this German quality. This model is equipped with a circular cutter.

- This tool is most suitable for a straight cutting of ceramic floor tiles with a thickness of up to 15 millimeters.

- With the help of such a tiltcake, you can make circular cuts with a diameter of 30 to 80 millimeters.

- This tool has a remote ruler, as well as a square, allowing to cut not only under direct (90 degrees), but also at an angle of 45 degrees. It is possible as an alternative to consider PRORAB plates.

Basic Plus 60.

- This is a high-quality professional tool model that can easily be used for various finishing works. Often, during operation, there is a need to customize tiles under certain conditions. It is for such conditions that this model is suitable.

- Complete with it also comes a special case. Cutting tiles is facilitated due to the presence of aluminum beds.

- In addition, to relieve and increasing the speed of the tiles, equipped with two nickel guides. These guides are characterized by increased rigidity. They also have a chromium coating, which reduces friction during work.

- The carriage of this model is made of polymeric material. This material is not subject to oxidation, he does not need lubricant and it does not clog.

- In addition, due to long handle, the force applied when cutting the tile decreases. As an alternative, you can consider Bosch tiles.

Thread selection of electric stoveturis

Main characteristics

The tile admits to cut with such tools such as Bulgarian, glass cutter and mechanical tiles. True, the result in quality will not be so good. In addition, not all kinds of tiles can be broken after the mechanical tool roller passed on it. A similar device is almost impossible to cut the tile, porcelain stonewares and stone slabs. Almost all mechanical stoves should not be used for cutting from the tile of a small strip. The maximum, to which they are capable, is cut off the strip with a thickness of at least 30-40 millimeters. Of course, such a task can be performed with an ushm with a cutting diamond disk, but this tool gives a lot of harmful stone dust. As a result, the health of the worker suffers from dust. Moreover, this dust is covered all around. It is very difficult to protect from her nearby residential premises.

To ensure universal work, which many popular tools cannot perform, special electrical machines for cutting tiles were manufactured. Such devices are very similar to the circular, but still have their differences. So, in plottlegores, like the circular, is directly located the engine and the cutting wheel. For ease of use, in some models the circle closes with a protective casing. More such tools are equipped with a stable reference platform or a durable bed having a swivel head. The water supply is supplied to the working area through special devices. Also, the plates are equipped with a universal positioning system of the workpiece.

Pluses and cons of electrical tiles

How to choose this tool should already be slightly clear. Electric stoves have several advantages over mechanical instruments and an ush.

- So, they allow you to make a more flat line.

- The number and sizes of chips are minimal after them.

- Such devices do not create dust in the workplace.

- They allow cutting material at an angle.

- In addition, they are safer and produced.

- These tools allow you to cut the tile diagonally, make grooves and cuts in the middle.

- Such models can easily be used for cutting from the edge of the tile of only a few millimeters, if necessary.

- The thickness of the workpiece is mainly affected by the depth of the circle immersion.

If you think that it is necessary to choose electrical tiles, then in addition to the advantages of tools, their shortcomings should be taken into account.

- So, this tool should not be used if cutting on the curved lines is necessary.

- If you need a high-quality and functional tool, it will cost a rather round sum.

What type of tile cutter is better

Diamond Pila

- This electric stovetur can be used for quick dry and wet cutting. Externally, it resembles a circular.

- Equipped with an engine with a handle and controls. There is a cutting disc with a casing. A disc with semi-fouls may also be present.

- In addition, there is a support sole of a stamped material. It contains the adjustment mechanism to adjust the inclination and depth of the dive.

- This is pretty simple, at the same time reliable and comfortable types of plates. The platform is capable of moving during operation not only relative to the canvas, along which the cut is carried out.

- There are models of tile cutters, equipped with rollers for easy turning machine by material. Some diamond instruments are also attached parallel emphasis.

- This is a maneuverable and easy tool that is not used in fixed fixing. His weight assembly ranges from 3 to 5 kilograms.

- With this tool applies small discs with a diameter of 80 to 150 millimeters. At the same time, the maximum cuticle depth ranges from 20 to 40 millimeters, which should even be enough for separating massive stone slabs. This largely contributes to sufficiently powerful engines.

- The maximum speed of spindle rotation ranges from 12 to 13 revolutions / min. This speed is positively affected by cutting.

- Separately, it is worth highlighting such a powerful model as eibenstock EDS 181. Its power is 2300 watts, weight is 7.7 kilograms, and the disk diameter used reaches 200 millimeters. The depth of cutting such a typewriter is 63 millimeters. This tool can be used for fairly large parts.

- If the cutting is dry, then a special container for collecting dust or a simple vacuum cleaner can be connected to a diamond saw. In the event that the wet cut is required, a small plastic barrel should be fixed on the housing. In this case, water will affect the cutting zone.

- Today manufacturers make their tools as compact as possible. There are machines that work from the battery, and not from the network. One of these machines is the Ryobi LTS180 M model equipped with a 18 volt battery. Instead, you can use any other battery from the ONE + brand system. For example, you can take a nickel-cadmium or lithium battery. Examples of wireless models are also Makita 4191 DWD. This tool has a NiCD battery with a capacity of 2.6 a * h and with a voltage of 12 volts. From the same manufacturer there is a Makita CC 300 DWE model equipped with a lithium-ion battery.

Stationary tiles (stonecase)

- Similar equipment allows you to get the best quality of the tile saw. They are equipped with a diamond disk with a continuous edge. During the processing of the workpiece stacked on a cutting table. At the same time, water is necessarily applied to the zone. Stationary construction tiles are divided into devices that the engine is located below and the device with the engine from above.

- Stationary tiles, in which the engine is located below, as a rule, occupy less space and, therefore, more compact. At the same time, they allow you to cut the tiles of large size. After all, there are no dimensions on the table, for example, supporting structures. An example of such a tool is the model Ryobi WS721S. Only with such massive details a large tile will have to travel through the line manually. After all, the guide bus can move away from the disk only as much as the size of the table is grabs.

- In addition, in a set of such a tool sometimes there is an angular, which can be used for cutting tiles, both diagonally and in parallel to it. An example of such plotkores can be called Nuova Battipav Queen 180 and Husqvarna TS 230 F. The engine in such devices is fixed motionless. In this case, the table has the ability to lean, which allows you to cut even at an angle of 45 degrees.

- In such slabs, drives with a diameter of 180 to 300 millimeters are used. At the same time, this disc appears on the bed very little. Because of what the depth of cut is small. This can be partially explained by the fact that the cooling of the residues occurs by immersing its lower part into the liquid. This principle is observed in all stoves with the lower engine location. Examples of such machines can be called KVC-461, Feida TC 180II, RUBI BL ND 180.

- As for the tilt circuits with the upper engine location, they put massive machines with an impressive bed. They have much larger sizes, and their design is heavier and expensive. They are good in that with the help of them you can get almost perfect accuracy.

The design distinguishes two versions of such tiles:

- Console machine. These machines are fixed on the console, and the mobile part is the mobile part. It is on it that the processed billet is fixed. Example: Husqvarna TS 400 F.

- Bridge machine. In these machines, the head on the contrary is movable. It moves along the rails. Example: SIMA VENUS 125.

Extra options:

- In the other construction, the head leans at an angle of 45 degrees, which makes it possible to make facenetics.

- In addition, both designs have a strict limit on the dimensions of the material being processed.

- In addition, the same design provides for the flow of water to the working area using the pump.

- Both of them have adjusting the depth of the cut.

- Complete each will be tires, stops and guides.

- No matter how much slab cutting machine is chosen, much here it depends on how mobile parts are performed qualitatively. More considerable importance is the overall stability of the design.

- It cannot be said that stationary tiles are fundamental, safer and reliable.

Selection of plastic cuts according to the characteristics of the power unit

- An important parameter of the power unit is the power and diameter of the work disk. So, for cutting concrete, bricks should choose quite powerful cars. In such plotting machines, the mass is capable of overcome for 100 kilograms. Therefore, absolutely there is no point in choosing more compact and less heavy models. Professional models of clinker machines are equipped with large-scale up-to-2200 watt engines. Such machines are ideal for severe operating conditions. An example of such a tilt-cutting machine is the Husqvarna TS100R model. In the RD-1200S model tool, a disk with a diameter of 350 millimeters is installed.

- If large parts are not planned to be used in finishing works, it is better to consider lower power plates of less power. For cutting tiles and facing panels not very large thickness, it is quite possible to use stoveture machines with a capacity of 750 to 1500 watts. Such devices will provide sufficient torque for circles up to 250 millimeters.

- Two important parameters when the machine is selected, the disk diameter and the depth of the cut depends on it. Thus, the diameter of the work disk is one of the main indicators. It is he who affects the depth of cutting. The cutting depth parameter itself reflects how thick the workpiece can be cut with this tool. This parameter is especially relevant when working with thick marble and concrete slabs. It is also important if you need cutting paving slabs or bricks. An example of such a slab should be called the RD-1200S model, which is equipped with a disk of 350 millimeters, and the maximum depth of the cut is 135 millimeters. For floor tiles, these parameters are not so important. Almost all modern machines with the upper engine are equipped with adjustment of the depth of the cut. This is done in order to avoid overheating, jamming and damage to the edge. It is best if the head of the slab-cutting machine will be fixed in the desired position. An example of such an apparatus can be called Nuova Battipav Class 670.

- Sometimes when the device is selected, pay attention to the frequency with which the spindle rotates at idle. However, this parameter is not particularly important in further working with the tool. Since to ensure high-quality cutting tiles, the high speed of rotation is not needed. It makes no sense to adjust this speed. It is enough to buy a tile carving, having a speed of rotation of a diamond disk at a level of 2-3 thousand revolutions per minute.

- Many modern tile cutting machines are equipped with various electronics. As for stationary tiles, they are not equipped with the system of maintaining the frequency of rotation, and there are no smooth start systems. But they have protection against overloads, made in the form of a thermal. Some manual machines for the overload indication are LEDs. If they caught fire, then this means that the tool flow should be slowed down. An example of such a typewriter is EibenStock EDS 181.

Portable diamond tiles are also equipped with protection against unintentional start. In the machines such systems are not provided, but there are buttons for the on and off tool. Due to the proximity of electricity, moisture developers use improved shock protection. Safety measures are used as:

- high-quality cords,

- double insulation windings,

- built-in Uzo,

- tearing automata

- system of waterproof seals and housings.

Thus, a person working with the tool will be reliably protected from electric shock. However, grounding fixed machines are still necessary.

Manual tiles - video.

Electric tiles - video.