Facing the stove with ceramic tiles will not only make its surface aesthetically more attractive, but will also contribute to improving heat transfer to the room. But in order for the tile to serve for many years, it is necessary to comply with technology. On the features of work - in the article materials.

Content

What materials can be used for facing the oven tile

The mode of operation of the stove dictates increased requirements for the selection of materials to finish its surface. It is important to know what tile and what adhesive solution must be selected. The highest temperature is able to withstand the following materials:

- The mixture for plastering works intended for furnaces. This is a special mixture capable of withstanding a plurality of heating cycles to high temperature and cooling.

- Plastering metal mesh required for high-quality and reliable gluing ceramic tiles. The grid binds the facing material into a single integer.

- Tile glue - a special heat-resistant composition.

- Ceramic tile capable of withstanding heating to 600 ° C.

In addition to ready-made plaster and adhesive mixes of Quick-Mix, Ceresit, "Plovetonite Super Fireplace", "Extra" (B-107), you can use mixtures of your own preparation. To do this, the PVA, asbestos and clay are added to the cement-sandy solution. Resistance to temperature is increased by adding salts in the proportion of 1 kg / 12 liters of the mixture.

Among the variety of options for ceramic tiles, for facing the furnace is suitable:

- glazed ceramics;

- clinker;

- majolica;

- tiles;

- porcelain stoneware;

- terracotta.

The tile should be low and have a thickness of at least 8 mm. The largest side of the tile should not exceed 200 mm.

Tip: Tile for facing the stove should be purchased with a margin. You need to add 10% for the "trimming" to the amount calculated on the area, to compensate for the possible marriage and on the battle.

Facing Technology Furnace Ceramic Tiles

Features of the facing of various types of furnaces are that before the design should work for at least two months. This is necessary in order for the masonry of the furnace gave shrink. This process, due to repeated heating, passes faster than in conventional brick walls, but as a result, cracks are often formed. The algorithm of work on facing the furnace is next.

How to prepare the surface of the stove to facing tiles

From compliance with the rules for the preparation of the furnace to cladding depends on the quality of the tile sticking and its service life. Preparation is performed in stages.

- Dismantling of old coating and surface preparation to facing tiles with their own hands. It is necessary to carefully clean the brick from whitewashing and plaster (for old furnaces) with a spatula and metal brush.

- The surface is purified from dust and processed by primer deep penetration. It will "connect" the microparticles of building material, make the laying more durable. The soil is applied two or three times: until his absorption stops being active.

- Fastening reinforcing grid. To do this, in brickwork, the furnace chopulates a lot of holes with a diameter of 6 mm for the bierbach dowels 6 × 40 mm. Such dowels are used without plastic fillers, which is due to the high surface temperature. The metal grid is stretched and fixed with dowels in increasing about 250 mm.

- After mounting the grid, the dust formed is sweeping, and the stove is once again handled the primer.

- We mix the plastering solution (it should be slightly liquid) and confuse the grid.

- After drying the first layer of plaster on the furnace, an aligning layer of plaster is applied. In order to get a flat surface, set beacons, between which the plaster is distributed with a wide spatula or rule.

- After drying, the plaster twice is processed by primer. After the first applying, the primer must dry completely.

IMPORTANT: Special attention should be paid to the process of installing beacons. To do this, use special metal profiles that are fixed on a plaster solution. The position of the lighthouses check the level.

Preliminary drawing and cutting tiles for furnace cladding

In order for the tile on the surface to be organically, it is necessary to properly distribute it on each side of the furnace. It is important to know how to measure the measurement and calculation of the tile. While working, enjoy the following recommendations:

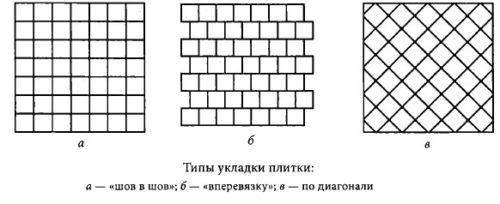

- Considering the design and sizes of the tile, it is necessary to determine the cladding method. The main options for laying the tile do it yourself: rows without dressing (seam in seam), rows with a dressing (with a displacement), diagonally.

- The width of each side is measured to calculate how much whole tiles fit in the row and what will be the size of the "trimming". It is important to avoid narrow "trim" (they look not organically). It is required to decompose the tiles along the walls from the edge to the edge so that they filled the side of the oven, after which it is removed alone, and the rest to distribute from the center to the edges.

- The height of the flicted side of the furnace is measured, the amount of entire rows vertically is determined. In order for the upper row to be laid in the whole, "trimming" should be shifted towards the lower, first row.

Laying tiles on the oven: phased description

The following tools and fixtures will be needed for laying tiles:

- slab;

- toothed spatula;

- trowel (Kelm);

- cellular machine (Bulgarian) with cutting and sharpening circles;

- marker;

- roulette;

- level;

- plastic crosses 2 mm;

- electrode and mixer for the preparation of the mixture;

- capacity for mixing the solution;

- tile cleaning vehicle.

Facing technology provides a certain sequence of actions:

- With the help of the trunk, the tile is applied adhesive solution and is uniformly distributed to the toothed spatula.

- The tile is pressed against the facing surface, ranging from the left lower angle. It is important to put the first tile correctly: the position of the remaining tiles depends on this. The correct gloveting of the first tile and the remaining is controlled by level. At the same time, the left side must coincide the vertical of the corner of the stove.

- The second and third rows are stacked immediately after the first. Between the tiles, remote plastic crosses are inserted. After laying three or four rows, a break for two or three hours. The technological pause is necessary to frighten the glue, otherwise the facing can be asked under its own weight.

- After laying the tile, it should be wiped with a rap, to clean the adhesive traces.

- After three days, the seams are filled with grout, for which the special composition is also used.

Tip: The corners of the stove are drawn up with a metal profile or are formed with a tile with ragged grinding chams.

How to bust oven

The technology of facing in the articles of the furnace at the stage of its construction is complex and is available only to those skilled in the art. For the acting stove, a more affordable method is used. The phased description is as follows.

- In the brickwork drill holes with a diameter of 6 mm for the bierbach dowels.

- Dowels cling to a wire designed to communicate tiles and bricks in the masonry. Wire winds around a dowel hats. The dowel in the masonry is not fully driven, and so that the hat remains outside.

- Tiles are installed on the hats of the dowels.

- The space between the masonry and tiles is falling asleep dry solution of heat-resistant glue. Subsequently, he absorbs moisture from the air and reliably glues the tile to bricks.

Tip: Tile should also post space before furnace. This is necessary in order to accidentally falling hot coal failed the fire.

The article describes in detail how plastering and laying the tiles with their own hands is carried out. But in order to have a more complete picture of what facing the furnace with their own hands - video with explanations of the wizard.