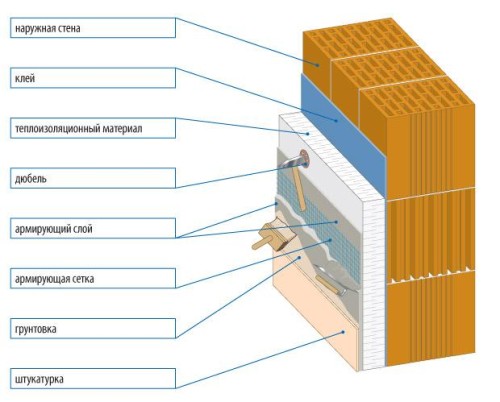

The grid under the plaster is a common material that is used for the strength of plaster composition. If the finishing coating is applied directly to the surface of the ceiling or wall, then the cracks will form on the basis of the material. After that, the coating will disappear completely. To avoid similar consequences and maximize the service life of the finishing material as the basis use a special grid. It takes on most of the load and thus prevents the appearance of cracks. In addition, the use of the grid makes the clutch of the plastering with the surface is more durable.

Content

Varieties of material

Specialists distinguish between several types of material, each of which varies with operational characteristics, target destination and cost. Consider more detailed every species:

- Metal plaster grid is used mainly for interior decoration work. The product is made with cells of different sizes based on cold rolled or stainless steel.

- Universal - the nets are made on the basis of polyurethane. In turn, they are divided into three groups depending on the cell parameters (small, medium, large).

- Laying mesh - made of polymer material. The cells of small size - 5x5 mm. This type of operation is provided for a brick base.

- Steel mesh - is made of steel rods that are welded at the nodes. The product may have a different mesh size.

- Fiberglass mesh. For the manufacture of this product is used specially treated glass fiber, which is obtained by passing the molten glass through small holes. The size of each cell is 5x5 mm. The grid of this species is fairly popular due to its high strength and resistance to the influence of different chemicals, and temperature extremes.

- Galvanized plaster mesh - a kind of material which is made by soldering galvanized rods at the nodes. Suitable for all types of finishes. In this case, different durability.

- Armaflex. The basis of this item is polypropylene. Mesh reinforced nodes differs, however applicable when applying a thick layer of plaster mixture. The cells have an average size - 12h15 mm.

- Plurima also made from polypropylene. Typically, the small size of the cells - 5x6 mm. Distinguished resistance to aggressive chemical components. It is used for exterior and interior decorating.

- Sintofleks - a polypropylene base, medium to large cells. It applies to all types of finishes.

The advantages of using

- Plastic mesh for plaster prevents occurrence of cracks on the coating, and increases the strength of finishing. In addition, it can be an alternative to metal products.

- These nets are not subject to corrosion, thus avoiding the formation of rust stains in the finish.

- This material has a low weight, it significantly facilitates the work.

- In addition, the grid on a plastic base provides high-quality adhesion to the solution and is suitable for finishing both outside and inside the building.

- Grid-type glass cloth has a light structure, resistant to the corrosive processes, and to the effects of chemical components. This is quite important property because plasters are characterized by alkaline environment, under the influence of which the metal begins to corrode.

- The glass is processed by special means that make the grid resistant to the negative effect of the alkaline medium.

- Also, the material does not lose its operational properties in low and high temperatures.

- Due to the flexibility, the mesh without effort is attached to the surfaces on which there are irregularities.

- The metal-based mesh does not allow the finishing material to be detached as a result of the effect of its own weight. Thanks to this property, this product is mainly used when applying a finishing coating on the ceiling.

- The plaster grid for external work on the first floors is also made from metal, since these places are most often mechanically exposed. Such meshs are the most suitable material when working with clay surfaces.

Features of choice

To make the right choice among such a variety of materials, initially follows from the type of work, which are supposed to be performed. Therefore, it is necessary to navigate the thickness of the plastering:

- if it does not exceed 20 mm, then the grid for plaster works is not required at all;

- with a thickness of the coating up to 30 mm, it is recommended to use the fiberglass;

- if it is necessary to apply a coating with a thickness of 50 mm, it is recommended to replace the fascination with another type of finish. For example, a ceiling that has significant defects, it is more expedient to establish a suspended or tensioning design.

To get a high-quality finish after applying a solution, in the process of work, you need to adhere to certain rules. The main aspects should include:

- compliance with the required proportions;

- ensuring in the premises of the required level of humidity and temperature.

In the absence of these conditions, the plaster coating will be low-quality. The use of the grid is a prerequisite when working with walls having significant defects, as well as with clay surfaces. Since in this case you need to apply a thick layer of plastering composition. The finish that was performed through this mesh retains its operational characteristics longer. Also, this product is necessary when the surface of the walls is reinforced before having wallpaper or painting.

Fastening the mesh under the stucco

The mounting method depends on the method of applying a plaster mix:

- by spraying;

- through the crossbar.

The lower layer is rejected from top of the applied composition using a grid. The most optimal option will be fastening the valves by means of special elements to the dry wall.

When finishing small surfaces, a plaster composition can be used as a fastener. In this case, it is applied point, then the plaster coating is evenly distributed throughout the workforce.

Metal Mesh Installation

This type of product is used when applied to a thick layer exceeding 30 mm. The most convenient in the work will be a grid with cells of 10x25, 10x10, 10x12. The advantages of the mesh on a metal basis are the low weight and ease of use. To cut it will not be much effort. Also after working with such a material there will be no traces of rust.

The workflow is made in such a sequence of actions:

- Before mounting the mesh on a metal basis, it is necessary to pre-process and degrease it. This can be done with the help of ordinary water or wet vet.

- Next from the grid should be cut the canvas. To determine the sizes, you need to focus on the placement method - along or across.

- If rusts are located on the surface of the ceiling, the grid does not need to be divided into fragments. In this case, it is placed in general in the longitudinal direction regarding each seam.

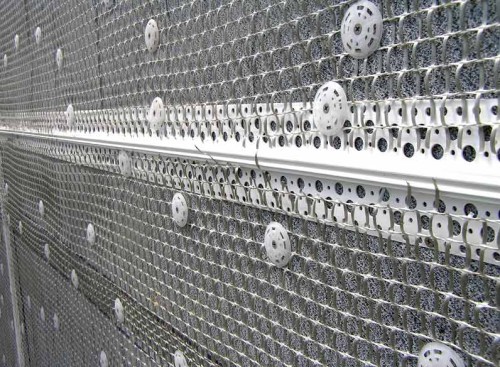

- At the next step, using a perforator, it is necessary to drill holes with a diameter of 6 mm. Their depth should be 3 mm to exceed the length of the dowel.

- A distance of 25 cm should be taken between each hole. Thus, 16 holes should be made on one square meter, in which the dowels are then inserted.

- After that, the mesh is fixed on the surface of the working base by means of screws and the mounting tape. In the process of fastening, you should not lose sight of the edge, they should be firmly fixed. The canvas are mounted.

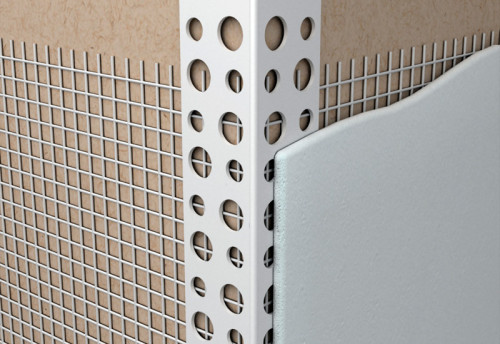

- In conclusion, plaster beacons are installed on the fixed grid.

Given the significant thickness of the finishing layer, the composition is recommended to be applied in two stages. At first, the first layer is applied to the grid bracket. To ensure good adhesion of the solution and the working surface, the plaster must be applied so that it penetrates through the grid. It should be pressed for this. After that, the solution is evenly distributed on the base by means of a grater or spatula. Then you should wait until the first layer of finishes dry and the second time to treat the surface.

How to mount a mesh for fiberglass plaster

Fiberglass mesh is used when applying a coating from 3 to 30 mm. When purchased, you should pay attention to the compliance of the characteristics of this grid standards. Cells must be at least 5x5 mm, as well as have a sufficient density indicator. In addition, the product must have resistance to alkaline substances.

Before starting installation work, the mesh is cut into fragments, the size of which depends on the method of location. The product can be placed in a longitudinal or transverse position. If there are rusts on the ceiling, it is necessary to place the grid fragments along each seam. In their absence, the method of accommodation does not matter. But the grid should cover the working surface completely. When cutting, it is recommended to leave a 14 cm reserve to strengthen the seams between the ceiling and walls.

The mount is carried out as follows:

- The first layer of solution is applied to the surface.

- The grid is stacked on top, which needs to be pressed into plaster.

- Next is applied the following layer. As a result, the grid turns out to be placed in the middle of the finishing coating. When performing this operation, you can wait for the drying of the first layer, but this is not a prerequisite.

When applying a thin layer, the fastening is recommended using screws and brackets. The work is performed in the following order:

- The beacons are made markups, according to which holes are drilled.

- Then the dowels are inserted into them.

- Screws are mounted on the level on each line of beacons.

- After that, the first layer is applied by the width of the grid.

- Then the grid is stacked on the coating.

- Next is fastened to the neighboring canvas. And thus the entire surface is processed. The canvases are located on each other, whose capture should be at least 10 cm.

- Then you need to wear metal lighthouses and apply plaster. When working with a fiberglass mesh, the plaster composition is applied evenly over the entire surface, after which it is smoothed towards the direction from the middle to the edges.

- To fix the ends of the grid, rules or a wide spatula are used.

Mounting on nails

Nails can also be used as fasteners. This method is suitable for fixing both metal and fiberglass grid. The plaster grid for internal works by means of nails is set as follows:

- Locking begins with an angle, from what exactly it does not have.

- Next, 20-30 cm should be retreating from the first nail and score the following. So the whole range is formed.

- When fixing the next line of nails, you need to shift 10-15 cm relatively to the previous one. So the fasteners will be installed in the chess sequence.

- Between the rows, a distance of 30 cm should be observed.

- After all nails are clogged on the working surface, you need to pull and fix the grid. In this case, it is necessary to monitor the canvas did not resist.

- To increase the reliability of the attachment, the upper part of each nail should be beatened. In the process of laying the canvases, they need to be placed on Van.

- This installation is completed, you can start finishing.

Conclusion

The plaster grid increases the coating strength, contributes to the best adhesion of the finishing layer with the base and significantly prolongs the period of operation of the finish. These products are produced on the basis of various materials, as a result of which are divided into several types. Each species has its own features of application. Installation is performed in several uncomplicated stages. Installation does not require considerable effort, so you can perform finishing using a grid yourself, without the help of specialists. To do this, it is enough to familiarize yourself with the procedure for work and ensure the required conditions.

Mounting rules are listed in the video: