There are many building materials to protect premises from moisture. Previously, it was used for this natural clay, beeswax, bitumen mastic, today the most popular waterproofer are rolled products. But they are invented so much that the injecting person will be very difficult to make the right choice and do not overpay for it. This article is created just for such cases - here you will find detailed characteristics of the most popular rolled materials for waterproofing and be able to choose the optimal option for your needs.

Content

What makes waterproofing make?

The very first fractured waterproofing was made on the basis of an oxidized bitumen. The process was as follows: bitumen heated and passed through it air bubbles, as a result, contact with oxygen caused the reaction, and a durable hydrophobic coating was obtained. Since raw bitumen had low heat resistance, it was replaced by oxidized, able to withstand heating to + 85c. However, raising heat resistance, the developers faced the problem of losing the elasticity of the material. Air bubbles, in fact, were a bitumen, and he became short-lived (the service life is no more than 5 years). Due to the high fragility, it was impossible to use on flexible surfaces.

The bitumen began to add modifiers to make it more elastic and prevent premature destruction. The material containing the APP and SBS modifiers has better performance, including high heat resistance to + 110c.

SBS is deciphered as styrene-styrene styrene and is a polymer artificial rubber with high elasticity. Coatings with SBS are characterized by good adhesion and high resistance to variable loads. The elasticity of such a material without base is from 1500% to 2000%. In the process of modifying the rolled waterproofing with the participation of the SBS, they create a polymer matrix in the form of a three-dimensional grid, which is obtained as a result of the interaction of polystyrene blocks. Inside the grid, bitumen is distributed as very small dispersion, which makes it high strength and reliable coating.

The second modifier is atalyactic polypropylene, or the APP, is a special thermal plaister with a high melting point. Thanks to this property, the APP makes rolled waterproofing resistant to heating, ultraviolet and stretching loads. To work in a hot climate, experts recommend choosing materials from the APP.

But to get rolled waterproofing, bitumen is necessary to apply for something. The basis use glass choles, fiberglass and polyester. Glassball consists of the finest glass threads placed in chaotic order. It does not differ in high strength or elasticity, so it is most often used in a pair with fiberglass. She, in turn, consists of intertwined threads and has greater tensile strength, but completely devoid of elasticity. In case the roof changes linear dimensions, fiberglass will only go away from the base, while maintaining the waterproofing qualities, and the canvas will immediately break.

Polyester is the most expensive and qualitative basis for bitumen consisting of chaotic fibers. Polyester has great strength, and its elasticity is 50%.

Classification of waterproofing

There are several criteria for the classification of rolled waterproofing: according to the method of fastening, labeling, price, composition, etc. Consider those of them that will be useful when choosing a material in the store.

By way of fastening

The method of attachment determines the convenience and speed of installation. Rolled waterproofing can be mechanically attached, adjust or stick on mastic. In the first case, it is fill it on the surface that is necessary to isolate, and nailed with brackets or nails. It can be fixed as each cut individually and the entire surface of the whole.

The welded waterproofing today is the most popular, since significantly simplifies construction and does not require special efforts. It is enough to put a roll on the surface, warm the back side by a gas burner and roll to the base. Gradually having warmed the bituminous layer, unfold the entire roll and remove waterproofing over the entire surface. The main advantage of this method of installation is the possibility of working on curved surfaces without losing protective properties.

The inlet rolled waterproofing is designed for sticking to special compositions and bitumen-polymer mastic.

Different methods of fixing materials are explained by their different compositions. So, rolls, fixed by brackets or nails, include fine sand. The welded waterproofing has a layer of a polyethylene film, which becomes viscous when heated and creates a sticky basis.

Not so long ago, another kind of rolled waterproofing appeared - self-adhesive:

Marking of waterproofing

On the packaging of rolled waterproofing, you can see the following abbreviations: HPP, TPP, EPP, HCP, TCP or ECP. They will be in a dead end, because to choose the appropriate material, you need to know what these letters mean.

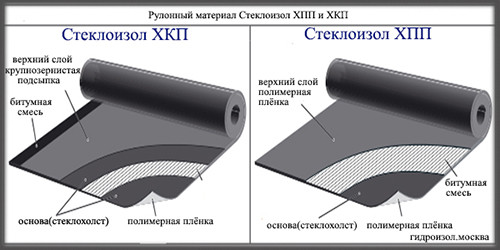

So, if at first it costs x, it means, the bitumen is placed on the basis of the glass cholester. T is the base of fiberglass, E - polyester. The last two letters indicate the materials of the layers from above and below, respectively. P is an easy-to-reflective film (in the melted rolls), to - shale or sandy sprinkle.

Depending on what is based on the basis of the material, which is a bitumen-polymer binding layer and what is the percentage of modifiers, the product class is determined.

Service life and cost

Even the most qualified specialist will not be able to call you accurate timelines for the service of rolled waterproofing, since they are determined separately for each specific case. The safety of protection depends on the climatic conditions, the characteristics of the coating, loads, the frequency of implementation of preventive repair work, etc.

The price of rolling waterproofing is calculated quadrature and depends on the class of material. On average, the Russian market is 1 kV. M bitumen-polymer waterproofing costs from 150 to 300 p.

Types of rolled waterproofing

The most common variety of rolled waterproofing is welded. It can be styled in two ways: full or partially moving. Depending on the roof slope, the number of layers varies - than it is stronger, the less layers needed. This is due to the fact that with a large bias, the moisture is not delayed on the surface and cannot destroy the protective coating.

The most popular materials of rolled waterproofing:

- tehnonikol;

- bikrost;

- eco-tape;

- glassizole;

- uniflex;

- linocur;

- uniflex-VENT;

- technoelast.

Waterproofing TechnoNIKOL

Technonol is a major corporation leading in the production of insulation materials for all sorts of needs. Tekhnonol rolled waterproofing is designed to protect the foundations, basement floors, walls and roofs. The range of materials is very wide, so for convenience it is divided into classes depending on the price and quality.

Premium rolled waterproofing:

- Teleelast Stop Flame - protection of the outer bed of the roofs. Contains antipyrene, so used for buildings with high fireproof requirements. The top layer is made of shale powder.

- Technoelast Prime is a type of inlet waterproofing, fixing on mastic or glue.

- TechnoElast Thermo - Universal Cutting Material, Different High Strength and Ability to transfer extreme weather conditions. He has a non-burning basis.

These are the three most popular premium products. The service life of each of them is from 25 to 30 years.

Waterproofing Locarrome

Designed to protect roofs with a small slope. The basis is fiberglass or glass cholester, treated on both sides by a bitumen-polymer binder and protective film. The bottom is easily placed, on top - a film with a coarse-grained supper from granite, slate or asbagal.

Locarur is also actively used for waterproofing foundations and pools. This is a universal protective material related to the business class and standard class. Does not contain in the composition of toxic components.

Waterproofing is removed by gas burner. For convenience, manufacturers apply an indicator pattern that disappears when the film is warmed up to the desired temperature. The material is guided by "on themselves", mounting the cuts of the brass 6-10 cm along and at least 15 cm at the ends of the rolls.

Glass insulation bicroelast

The bicroelast on the structure is similar to a linocome - an unbinding basis is processed from two sides by a bitumen with polymer additives. Bituminous layers are protected by special films with large or fine-grained powder.

Bicroelast is used to create a reliable waterproofing coating on the roofs with a small bias, the protection of foundations, walls of basements and basement floors. It does not lose elasticity even at a temperature of -10С and is able to withstand heating to + 85c. For this reason, SNiP allows it to apply it in all climatic zones.

Glass insulation of ecoflex

Rolled waterproofing for roofing, walls and foundations. Refers to business-class products with a service life from 15 to 25 years. Can be used to protect underground structures. It has a high degree of heat resistance and is able to withstand the heating to + 130c (there is an APP as part).

Fiberglass or polyester can be based on the basis. On both sides, the material is covered with bitumen layers with fillers and additives. From the top there is sprinkled from sand or slate, closed by a polymer film. The ecoflex is recommended for use in regions with a hot climate and in places with increased temperature modes.

Glass insulation of glassizole

Glassizol are made of glass cholester, fiberglass or mixed base, which is impregnated by bitumen. It is used both for roofing, and to protect walls, pipes, foundations, floor. Among the advantages of this material can be distinguished by non-combustion, durability (15 years), inconsistence of rotting.

The roofing and lining glass is distinguished, which is indicated in the labeling of the corresponding letters - "K" and "P". Both species are used for insulation of non-exploitable roofs with a slope of no more than 10 °.

Depending on the thickness of the bitumen impregnation layer varies the weight of waterproofing from 25 to 40 kg / roll.

Working with glassware is recommended at a temperature not lower than -10C in dry and windless weather. At temperatures below 0, it should be at first to hold the day in the warm room, otherwise it can crack. Before laying on a concrete, you must apply a layer of a primer that increases the adhesion of the material.

Glass insulation bikrost

Bikrost is one of the most popular insulating materials in the domestic market. There are several varieties depending on the basics and components applied to it. Thus, the bicrost on the glass cholester is suitable for economical owners, and if fiberglass is based on, it is possible not to worry about the strength of the coating. Choosing an expensive material on a polyester basis, it is better to have the skills of laying and at least minimal experience of such work.

Bicket is used as rolled waterproofing for floors and roofs. Shalasting sprinkle protects the material from the devastating ultraviolet exposure. The heat resistance of the material is up to + 80c, the binding begins to collapse at -15c.

Since there are no polymer additives as part of the biccrost, it does not differ good adhesion, but it is much cheaper than other waterproofing (which is explained by its popularity).

Glass insulation uniflex

Polymer-bitumen waterproofing class standard, which contains a SBS modifier. A glassic or polyester can be based on the basis of the material of the material.

The uniflex has good adhesion to any fundamentals, so it can be used to protect not only horizontal, but even vertical and inclined planes made of non-combustible materials. The uniflex is used to arrange roofing carpets of buildings, isolation of foundations, repair of old roofs, protection of underground tunnels and bridges.

Uniflex VENT is an improved variety of material that provides natural ventilation of structures and structures without loss of waterproofing qualities. Specialists recommend using the VEnt Uniflexal in a humid climate or to protect premises with high humidity. The peculiarity of this waterproofing is that it contains special vapor-having channels. This technology is unique in its operational characteristics. The binding layer is represented by bitumen, polymer additives, fillers and butadiene-styrene thermoelastoplast. From the bottom side there are strips of a bitumen-polymer substance, between which the fine sand is located. The cost of such waterproofing is impressive, but its quality and durability pays off any costs.

Choose waterproofing for the construction of the house, repairing the roof or any other purpose is not so difficult. The most important thing is to understand the principles of the material and rationally assess its operational capabilities.